Device and method for butting single-phase single-sheet transition conductor of bus duct connector

A connection device and a technology of busway, which is applied in the direction of conductive connection, open busbar installation, connection, etc., can solve the problems of uneven force, inability to achieve close contact, and inability of all conductors of conductive bars and busbars to be in close contact. The effect of large flow, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical problem to be solved by the present invention is how to balance the force on the entire contact surface of the joint conductors so that all the joint conductors are in close contact.

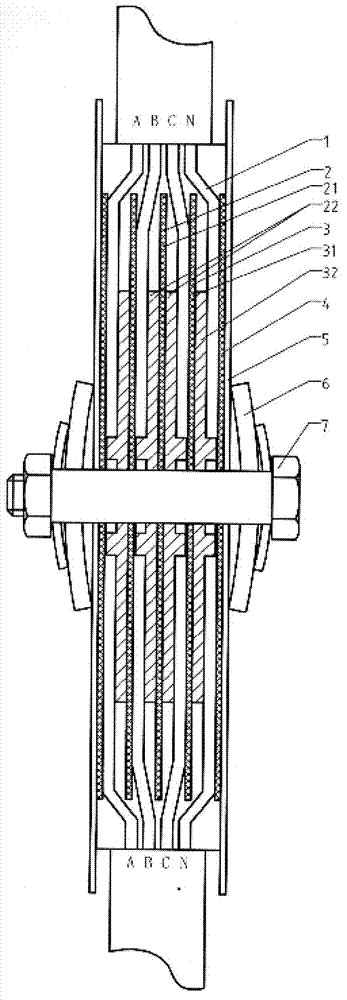

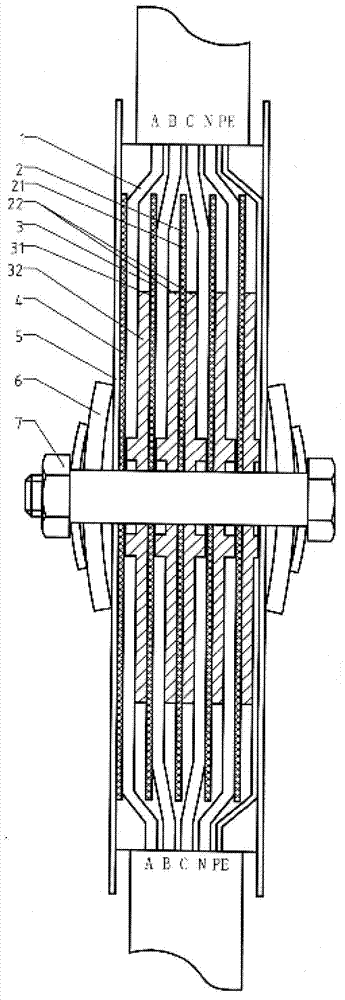

[0011] The connection method adopted by the busway joint of the present invention is a docking type, and the device includes double-blade busway joints 2 and single-blade busway joints 3 arranged in sequence. The sequence is: single-blade busway joint 3, double-blade busway joint 2, single-blade busway joint 3; double-blade busway joint 2 is composed of two-phase insulating sheets 21 and transition conductors 22, The single-blade busway connector 3 is composed of two-phase insulating sheets 31 and transition conductors 32; when the power supply is a 3-item 5-wire system, the arrangement sequence of the device is: single-blade busway connector 3, double-blade busbar Groove joint 2, single-blade bus duct joint 3, single-blade bus duct joint 3; fastening insulating bolts 7 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com