Method and device for ultralow-load stable combustion of pulverized coal fired boiler in power plant

A pulverized coal boiler, ultra-low technology, applied in the direction of combustion method, combustion using block fuel and powder fuel, combustion using liquid fuel and powder fuel, etc. No effect, pipeline deflagration and other problems, to achieve the effect of easy on-site transformation, fast response, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

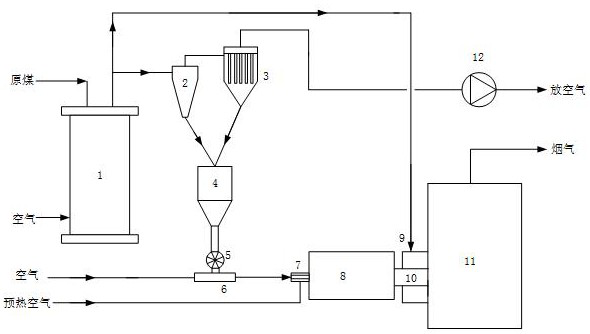

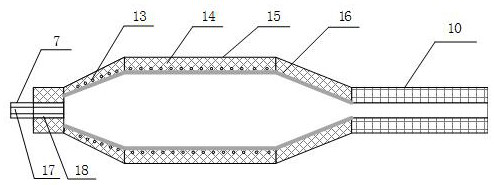

[0040]A method for ultra-low-load stable combustion of pulverized coal boilers in power plants involved in this embodiment includes the following steps: using high-activity Datong bituminous coal as raw material; firstly, using electric heating element 13 to preheat the stable burner to 800-850 ℃; the raw coal is first fed into the coal mill 1, and the raw coal particles are ground into coal powder with a particle size of less than 150 μm. Bypass, control the flow of induced draft fan 12, and the primary wind carrying 1-1.5% of coal powder enters cyclone separator 2 and bag filter 3, and the collected coal powder enters intermediate silo 4; the coal powder in intermediate silo 4 Under the control of the feeder 5, enter the gas conveyor 6, and control the ratio of air to pulverized coal to 0.5 Nm 3 / kg pulverized coal, the pulverized coal enters the burner 8 from the central channel 17 of the burner under pneumatic conveying, and the air flow rate at the outlet of the burner 7 ...

Embodiment 2

[0042] A method for ultra-low-load stable combustion of pulverized coal boilers in power plants involved in this embodiment includes the following steps: using high-activity Shenmu bituminous coal as raw material; firstly, using electric heating element 13 to preheat the stable burner to 750-800 ℃; the raw coal is first fed into the coal mill 1, and the raw coal particles are ground into coal powder with a particle size of less than 200 μm. bypass, control the flow rate of induced draft fan 12, and the primary wind carrying 1.5-2% coal powder enters cyclone separator 2 and bag filter 3, and the collected coal powder enters intermediate silo 4; the coal powder in intermediate silo 4 Under the control of the feeder 5, it enters the gas conveyor 6, and the ratio of air to pulverized coal is controlled to be 1 Nm 3 / kg coal powder, coal powder enters the burner 8 from the center channel 17 of the burner 7 under pneumatic conveying, and the air flow rate at the center outlet of the...

Embodiment 3

[0045] A method for ultra-low-load stable combustion of pulverized coal boilers in power plants involved in this embodiment includes the following steps: using Yangquan anthracite with low activity as raw material; ℃; the raw coal is first fed into the coal mill 1, and the raw coal particles are ground into coal powder with a particle size of less than 100 μm. bypass, control the flow rate of induced draft fan 12, and the primary wind carrying 2.5-3% coal powder enters cyclone separator 2 and bag filter 3, and the collected coal powder enters intermediate silo 4; the coal powder in intermediate silo 4 Under the control of the feeder 5, it enters the gas conveyor 6, and the ratio of air to pulverized coal is controlled to be 1 Nm 3 / kg pulverized coal, the pulverized coal enters the burner 8 from the center channel 17 of the burner 7 under the pneumatic conveying, and the air velocity at the center outlet of the burner 7 is controlled to 35m / s; Passage 18 enters the burner 8, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com