Full-automatic destacking, stacking and packaging system

A fully automatic and depalletizing technology, which is applied in the fields of packaging systems, fully automatic depalletizing, palletizing, and operating systems, can solve problems such as high labor intensity, poor operating environment, and impact on workers' production safety and physical health, so as to reduce Transport costs, increase corporate profits, and increase the number of target customers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

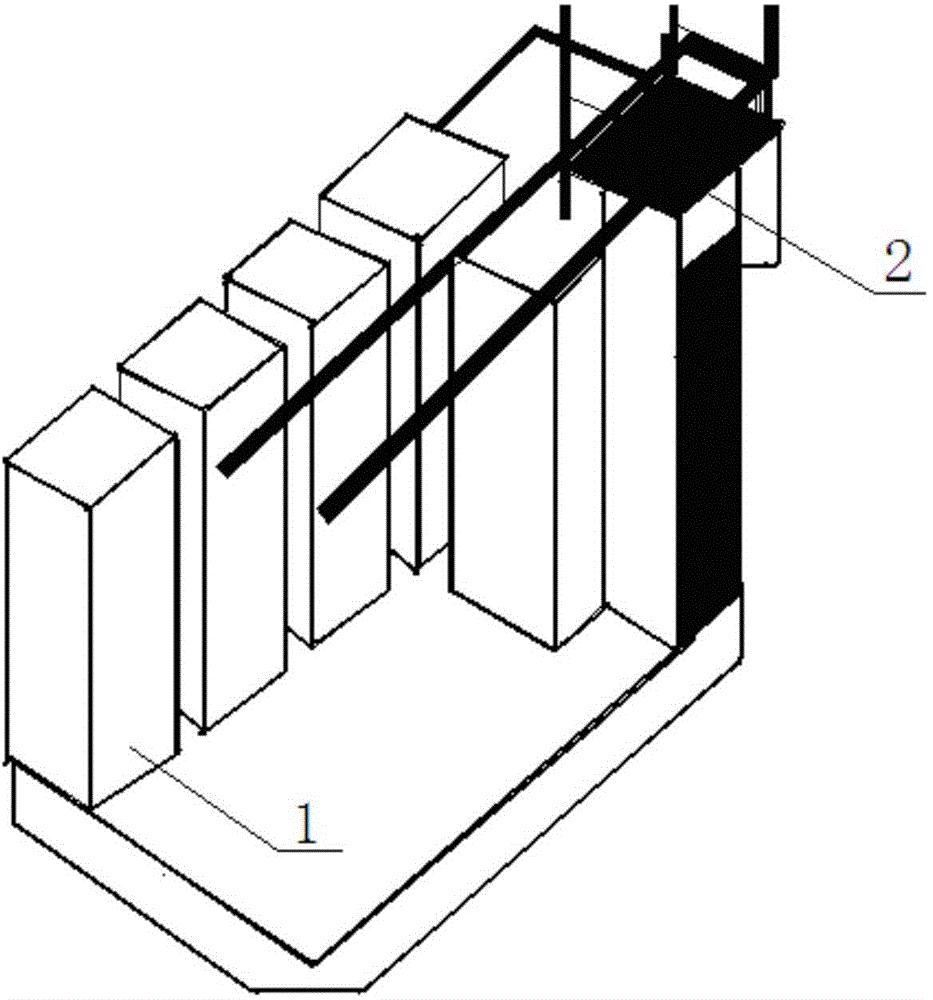

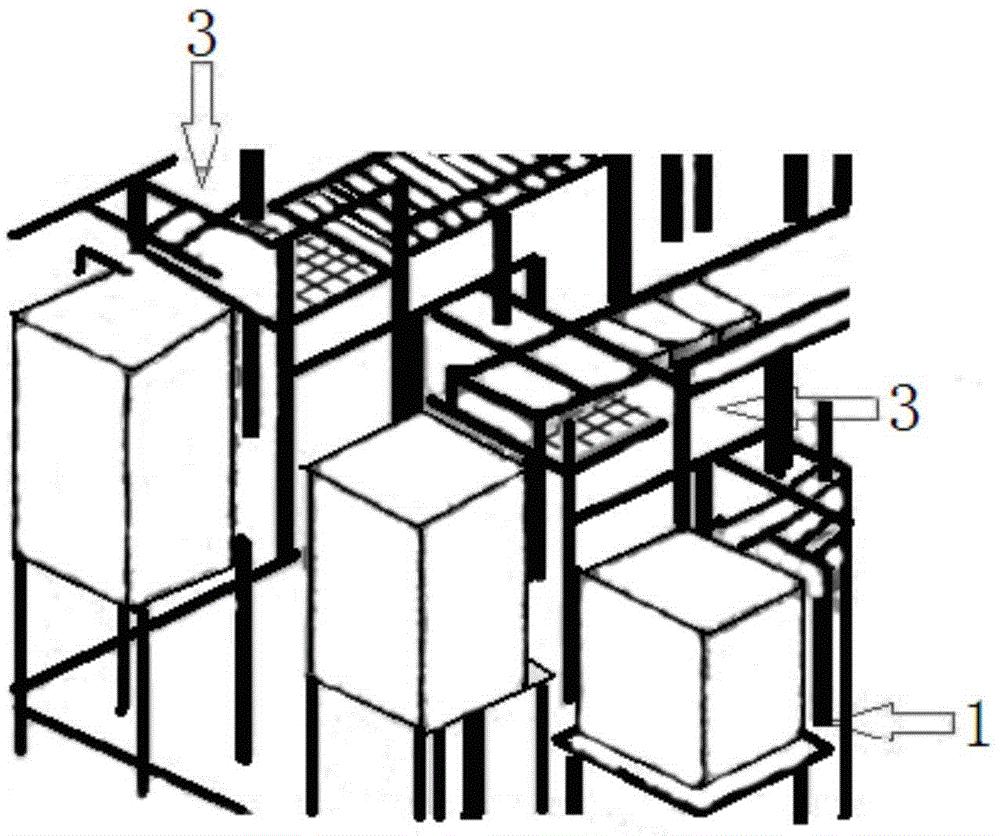

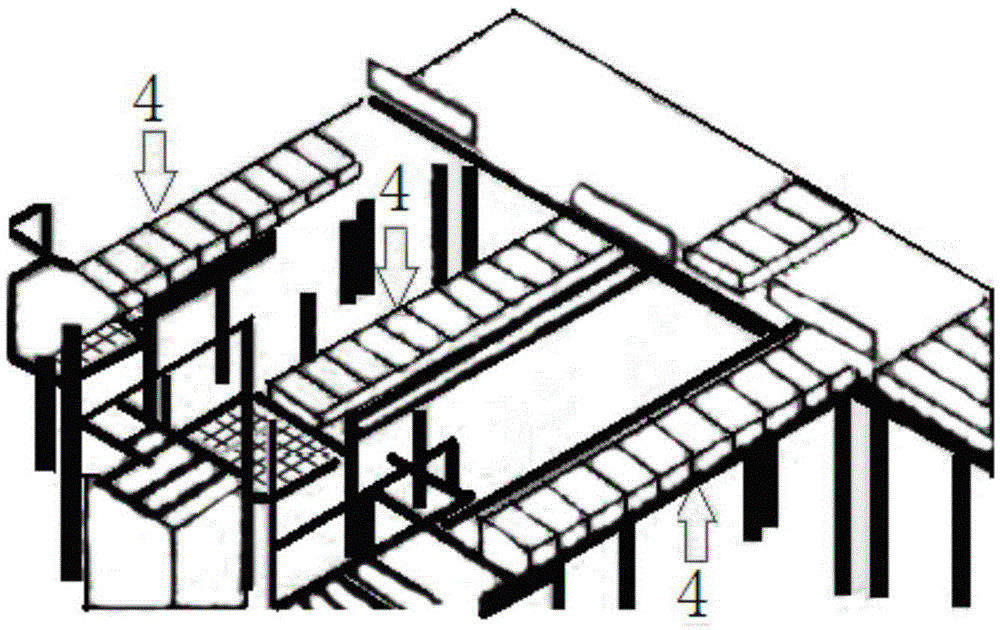

[0033] The fully automatic depalletizing, palletizing and packaging system provided by the present invention applies digital control technology, servo motor application technology, hydraulic control technology, pneumatic control technology, conveying intelligent marshalling technology and programmable control technology to depalletize, depalletize, Grouping, counting, palletizing, packaging and other production needs are planned and controlled in a unified manner to realize the automatic control operation of the whole process and make up for the technological gap in the full automation of the whole process of brick making in the brick and tile industry.

[0034] The fully automatic depalletizing, stacking and packing system provided by the present invention is specifically expressed as:

[0035] Intelligent positioning and single-stack brick-holding pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com