Axial excitation low-speed synchronous motor with axial straight-through tooth integral rotor

A synchronous motor and integral rotor technology, which is applied to synchronous motors with static armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit static parts, etc. The processing process is cumbersome and the reliability of the motor is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

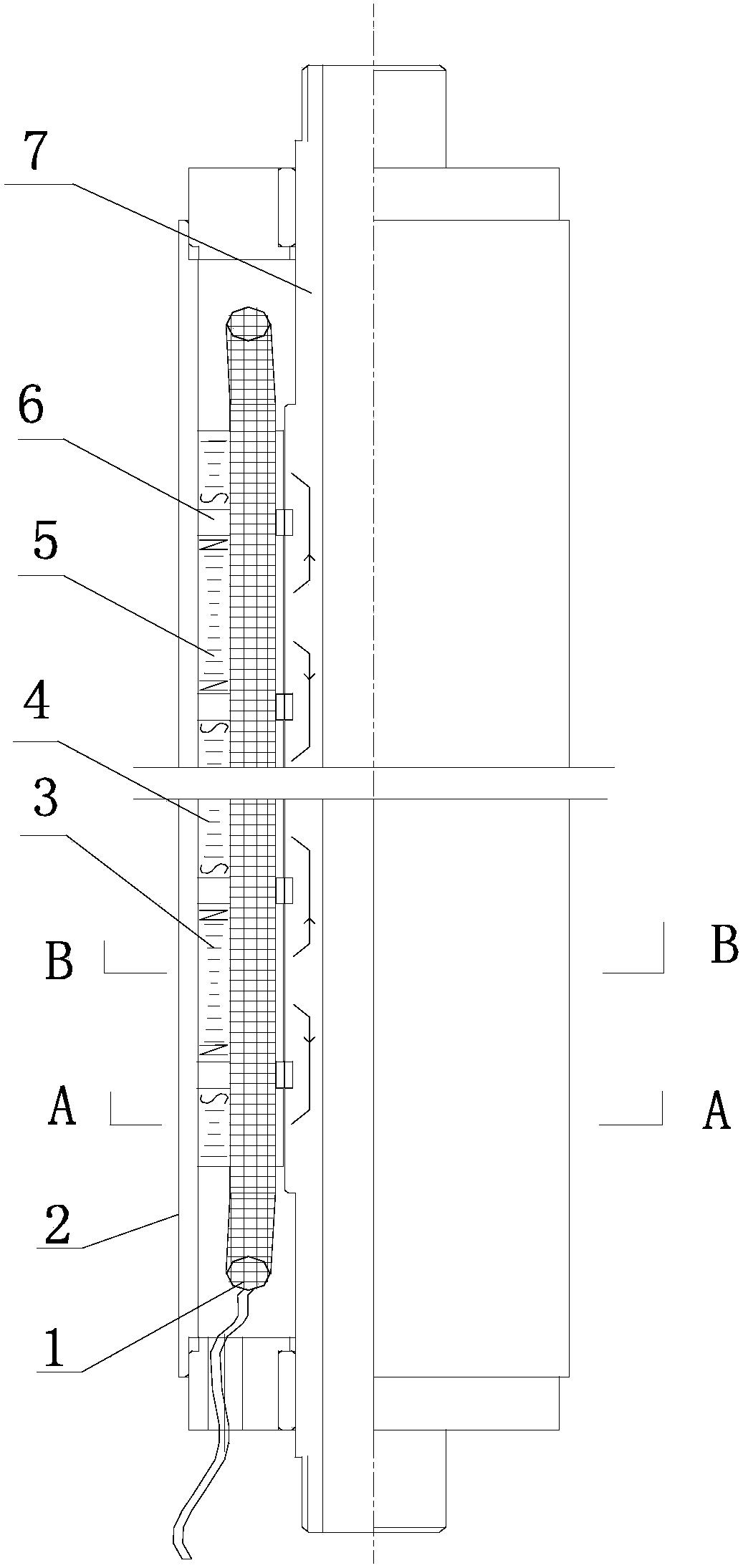

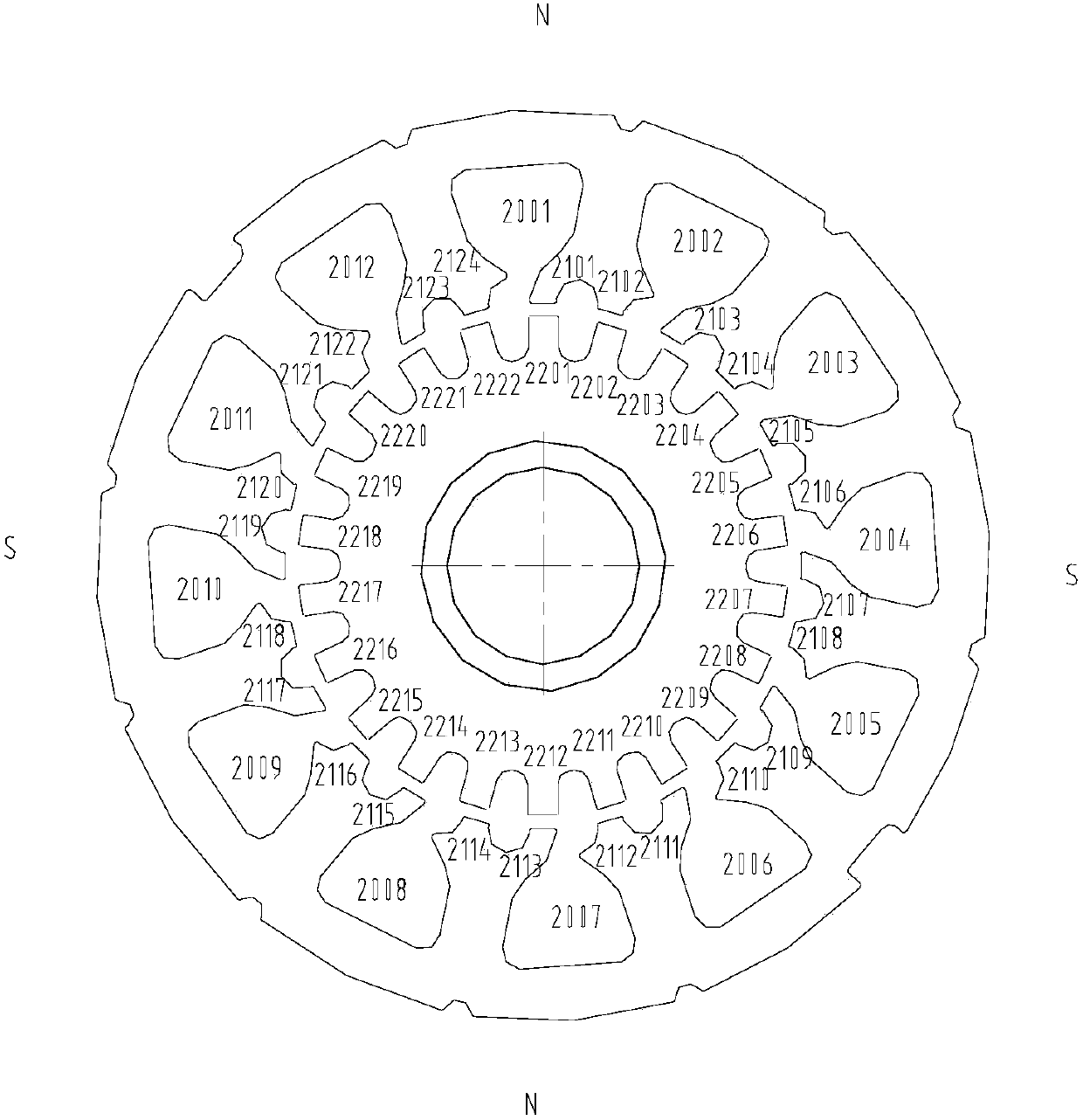

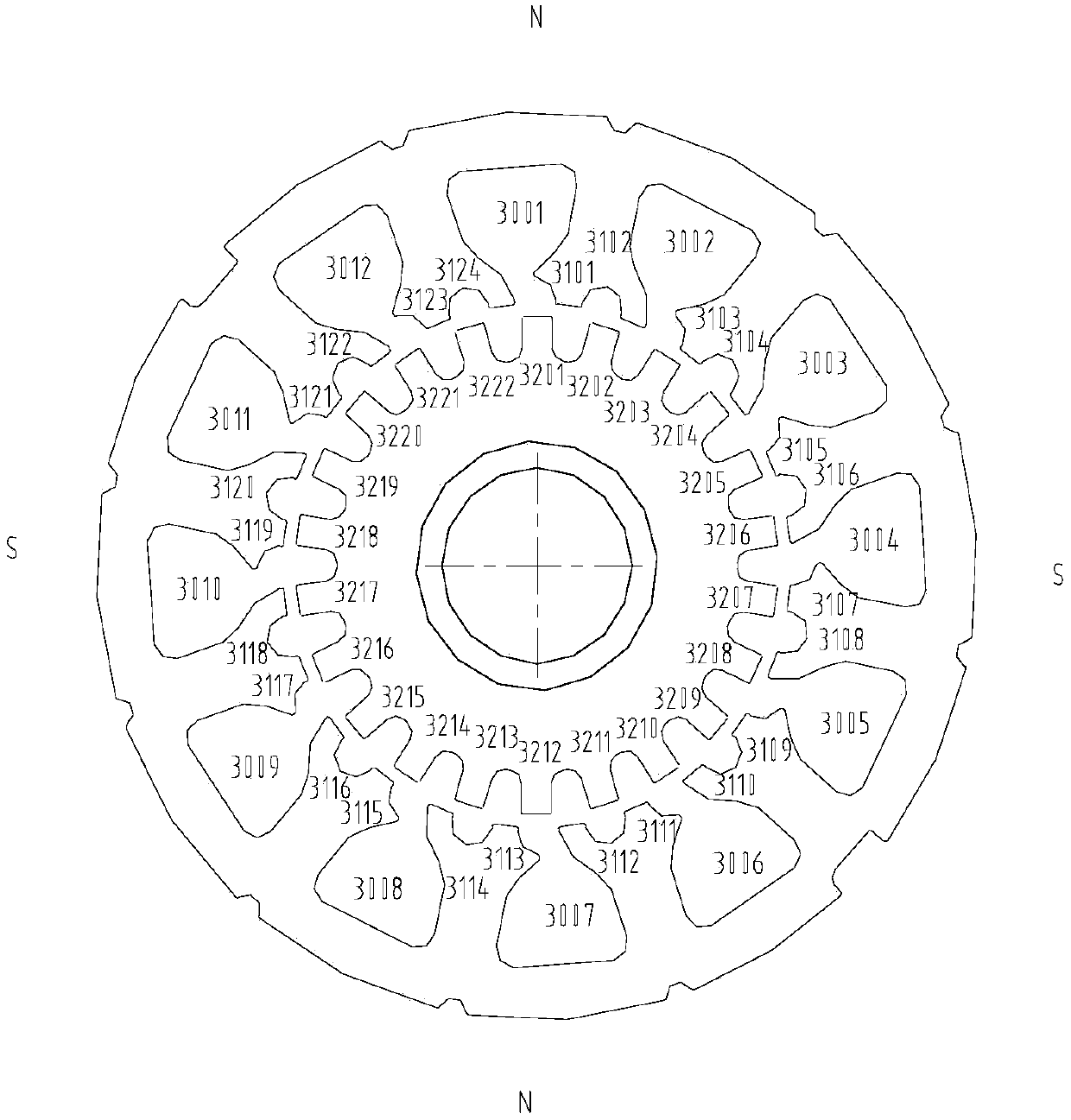

[0032] Such as figure 1 The present invention shown is an axial excitation low-speed synchronous motor with an axial through-tooth integral rotor, such as Figure 8 As shown, the segmented stator core 3 of the S polarity segment and the segmented stator core 4 of the N polarity segment are respectively shifted from the large and small teeth in the circumferential direction of the slots, such as Figure 9 As shown, the stator core punching sheet 5 is stacked, the S polarity segment stator core 3, the N polarity segment stator core 4, and the annular excitation coil 6 are coaxial in sequence in an axial forward and reverse manner. Installed and fixed in the casing 2, such as Figure 10 , Figure 11 As shown, the axial through-tooth integral hollow rotor 7 is coaxially installed in the inner cavity of the segmented stator core 3 of the S polarity segment and the segmented stator core 4 of the N polarity segment. An electromagnetic air gap of 0.2 mm is left on the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com