Ultra-low load stable combustion method and device for coal-fired boiler

A technology of a coal-fired boiler and a stabilizing combustion device, which is applied in the combustion method, the burner for burning powder fuel, the burner, etc., can solve the problem that the coal-fired unit is difficult to maintain stable combustion, and achieves easy on-site renovation and high burnout rate. , fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

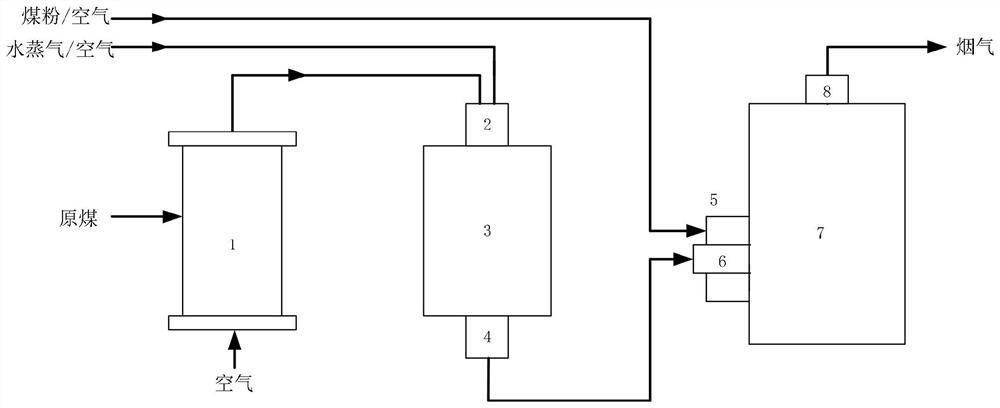

[0036] The ultra-low-load stable combustion method for a coal-fired boiler based on the partial gasification of ultra-fine pulverized coal involved in this embodiment includes the following steps: using high-activity Shenmu bituminous coal as a raw material;

[0037] In step 1, the raw coal is sent to the ultra-fine coal mill 1, and the raw coal is ground into ultra-fine pulverized coal with a particle size of less than 45 μm, of which the ultra-fine pulverized coal with a particle size of less than 10 μm accounts for ~ 55%; air is carried by adjusting the air volume. The ultrafine coal powder is discharged from the top of the ultrafine coal mill 1; the mass ratio of air to ultrafine coal powder is 3.5:1;

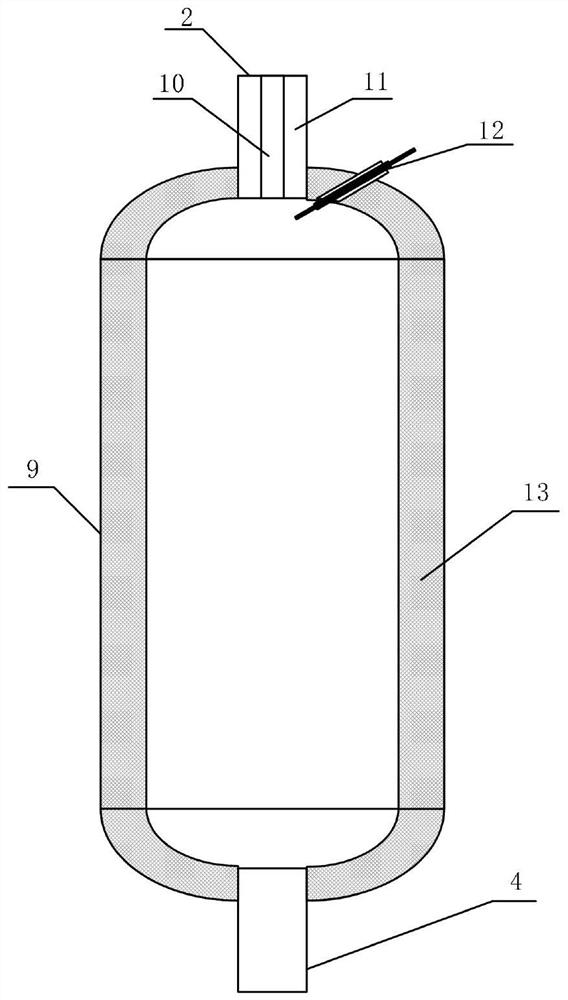

[0038] Step 2, the air carries the ultra-fine coal powder and is injected into the gasifier 3 from the central channel 10 of the burner 2 at the top of the gasifier; the gas flow rate at the outlet of the central channel 10 is controlled to be 40 m / s;

[0039] Step 3, ignit...

Embodiment 2

[0044] The ultra-low-load stable combustion method for a coal-fired boiler based on the partial gasification of ultra-fine pulverized coal involved in this embodiment includes the following steps: using high-activity Inner Mongolia lignite as a raw material;

[0045] In step 1, the raw coal is sent to the ultra-fine coal mill 1, and the raw coal is ground into ultra-fine pulverized coal with a particle size of less than 45 μm, of which the ultra-fine pulverized coal with a particle size of less than 10 μm accounts for ~50%; air is carried by adjusting the air volume. The superfine coal powder is discharged from the top of the superfine coal mill 1; the mass ratio of air to superfine coal powder is 1.5:1;

[0046] In step 2, the air carries the ultra-fine pulverized coal and is injected into the gasifier 3 from the central channel 10 of the burner 2 at the top of the gasifier; the gas velocity at the outlet of the central channel 10 is controlled to be 60 m / s;

[0047] Step 3, ig...

Embodiment 3

[0052] A method for stabilizing combustion at an ultra-low load of a coal-fired boiler based on the partial gasification of ultra-fine pulverized coal involved in this embodiment includes the following steps: using low-activity Yangquan anthracite as a raw material;

[0053] In step 1, the raw coal is sent to the ultra-fine coal mill 1, and the raw coal is ground into ultra-fine pulverized coal with a particle size of less than 45 μm, of which the ultra-fine pulverized coal with a particle size of less than 10 μm accounts for ~65%; air is carried by adjusting the air volume. The superfine coal powder is discharged from the top of the superfine coal mill 1; the mass ratio of air to superfine coal powder is 2.5:1;

[0054] In step 2, the air carries the ultra-fine pulverized coal and is injected into the gasifier 3 from the central channel 10 of the burner 2 at the top of the gasifier; the gas velocity at the outlet of the central channel 10 is controlled to be 30 m / s;

[0055] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com