Separation recovery method of enameling technique exhaust

An enamelling process, separation and recovery technology, applied in separation methods, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as reducing energy recovery efficiency, environmental pollution, and recovery efficiency needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

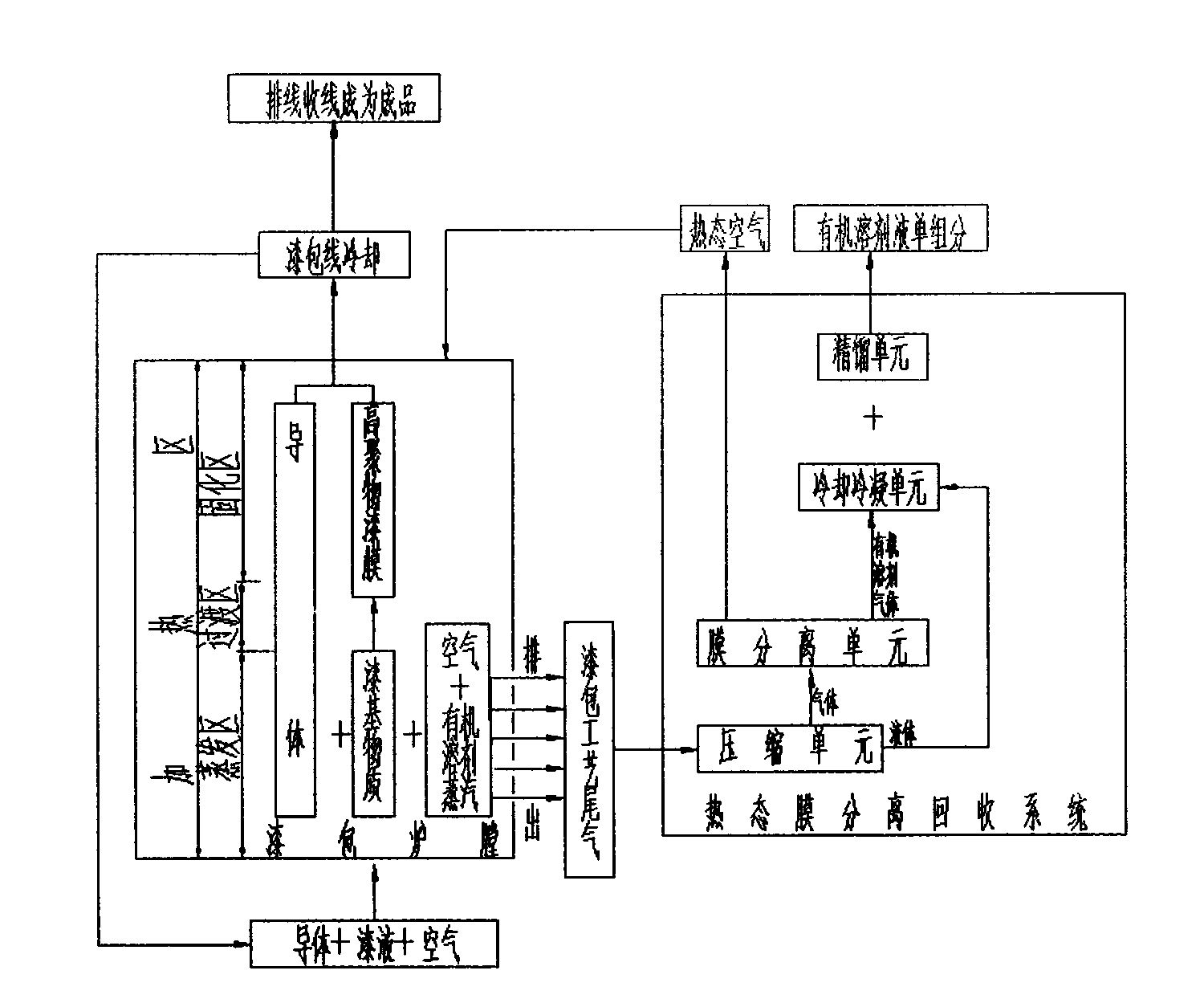

[0025] Example 1: figure 2 The flow chart of the present invention's hot-state membrane separation recovery enamelling process tail gas; as figure 2 As shown, when the conductor is coated with varnish liquid and air enters the enamelled furnace for heating, when the organic solvent in the lacquer liquid reaches the volatilization temperature, it begins to volatilize gradually, becomes solvent vapor and mixes with the air in the furnace to become enamelled process tail gas, At this time, the fan sucks the high-temperature enamelled tail gas out of the inner furnace of the enamelled furnace from the evaporation area of the enamelled furnace in time, discharges it continuously and injects it into the hot membrane separation and recovery system.

[0026] The thermal membrane separation recovery system consists of compression, membrane separation, cooling condensation and rectification units in sequence.

[0027] When the hot enamelling process tail gas enters the compression ...

Embodiment 2

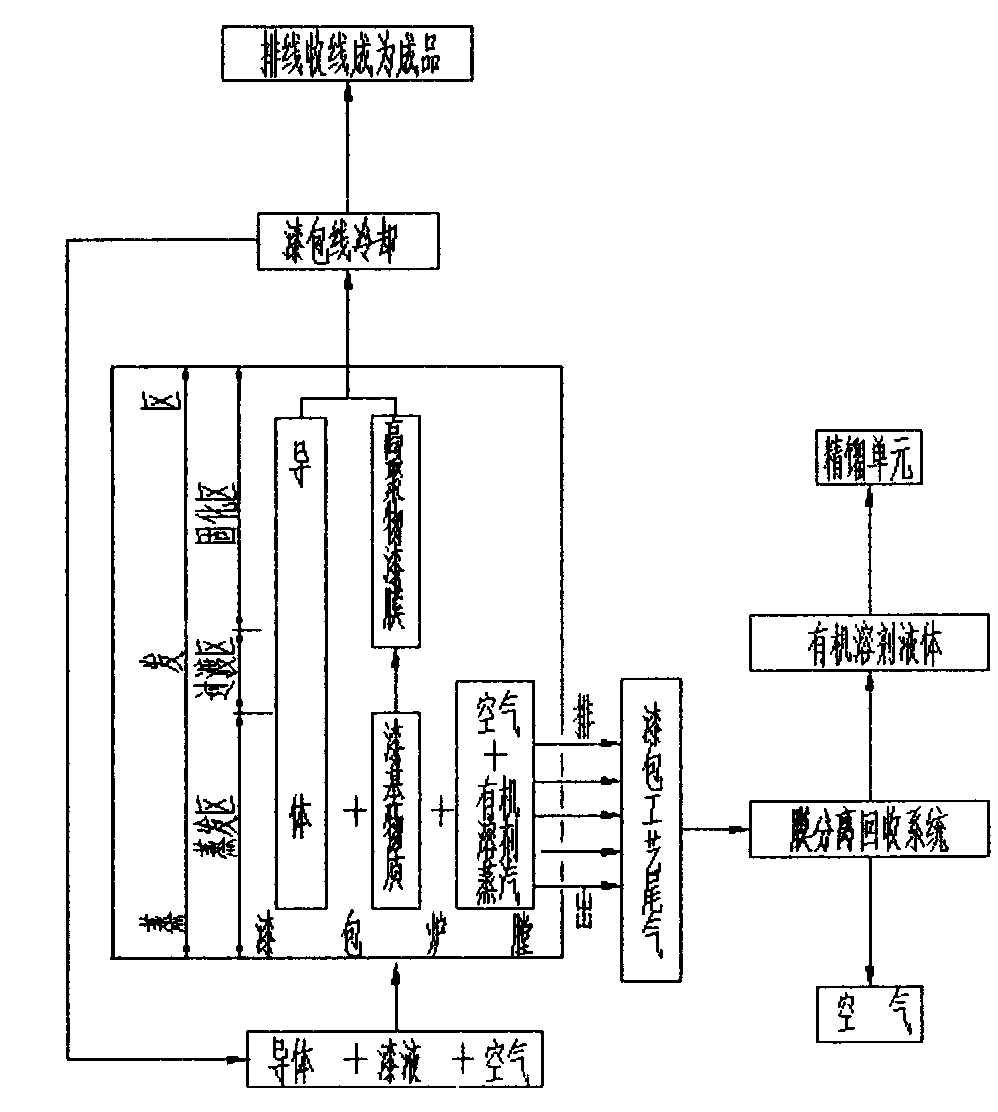

[0032] image 3 The flow chart of the present invention's cold state direct method membrane separation recovery enamelling process tail gas; image 3 As shown, when the conductor is coated with varnish liquid and air enters the enamelled furnace for heating, when the organic solvent in the lacquer liquid reaches the volatilization temperature, it begins to volatilize gradually, becomes solvent vapor and mixes with the air in the furnace to become enamelled process tail gas, At this time, the fan sucks the high-temperature enamelled tail gas out of the inner furnace of the enamelled furnace from the evaporation area of the enamelled furnace in time, discharges it continuously and injects it into the hot membrane separation and recovery system.

[0033] The cold-state membrane separation direct method recovery system consists of a heat exchange unit, a compression unit, a condensation unit, and a membrane module separation unit in sequence.

[0034] When the enamelling proces...

Embodiment 3

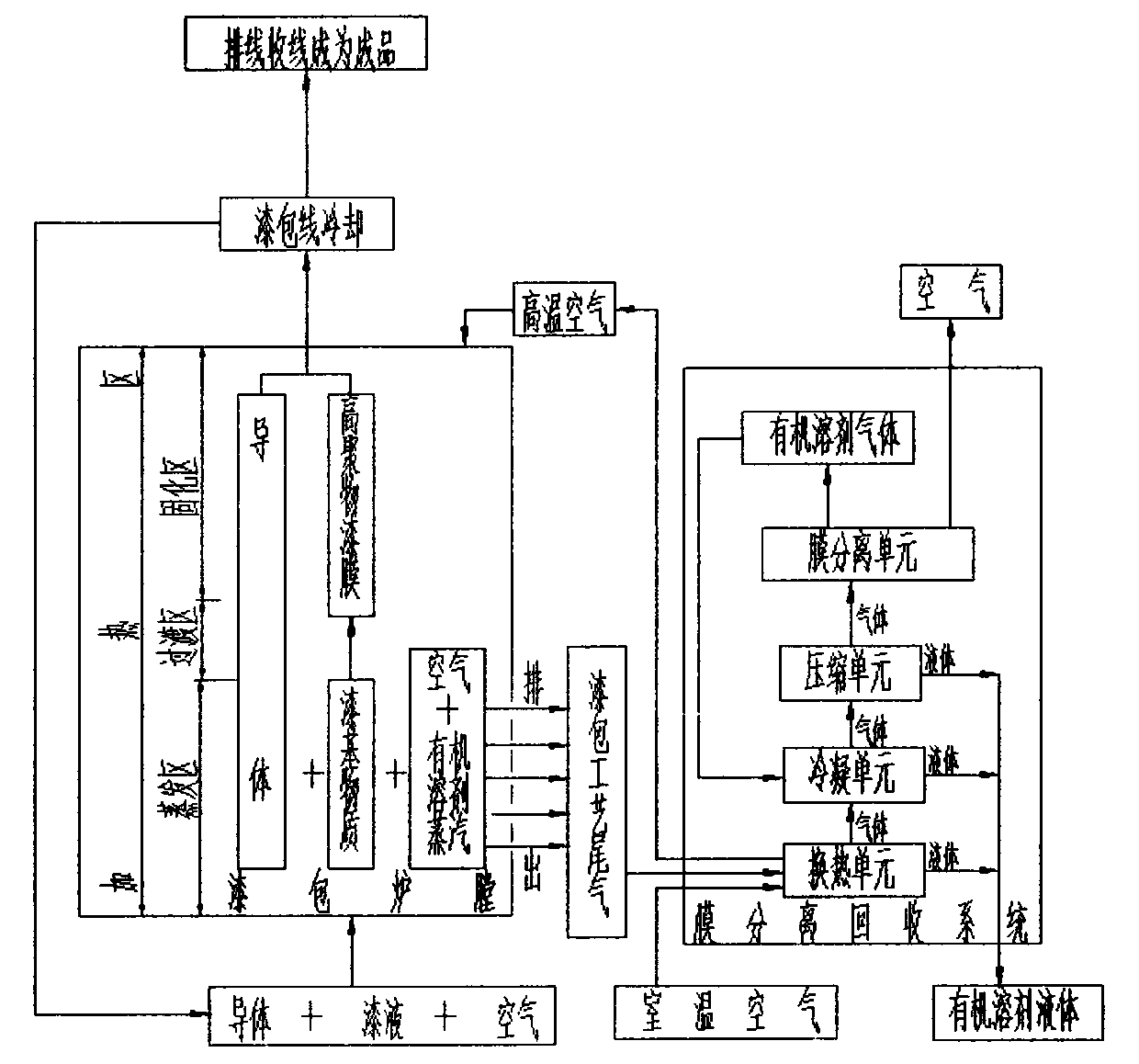

[0039] Figure 4 The flow chart of the present invention's cold-state deoxygenation and nitrogen removal method membrane separation recovery enamelling process tail gas; Figure 4 As shown, when the conductor is coated with varnish liquid and air enters the enamelled furnace for heating, when the organic solvent in the lacquer liquid reaches the volatilization temperature, it begins to volatilize gradually, becomes solvent vapor and mixes with the air in the furnace to become enamelled process tail gas, At this time, the fan sucks the high-temperature enamelled tail gas out of the inner furnace of the enamelled furnace from the evaporation area of the enamelled furnace in time, discharges it continuously and injects it into the hot membrane separation and recovery system.

[0040] The cold-state membrane separation direct method recovery system consists of a heat exchange unit, a compression unit, a condensation unit, and a membrane module separation unit in sequence.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com