backside illuminated cmos image sensor

An image sensor and backlighting technology, which is applied in the field of image sensors, can solve the problems of CMOS image sensor fading and affecting imaging quality, and achieve the effect of improving display fading, improving imaging quality, and reducing crosstalk of electrical signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

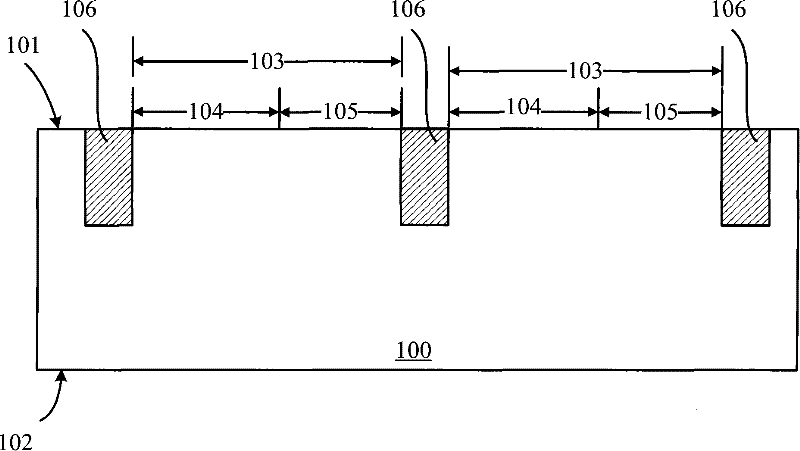

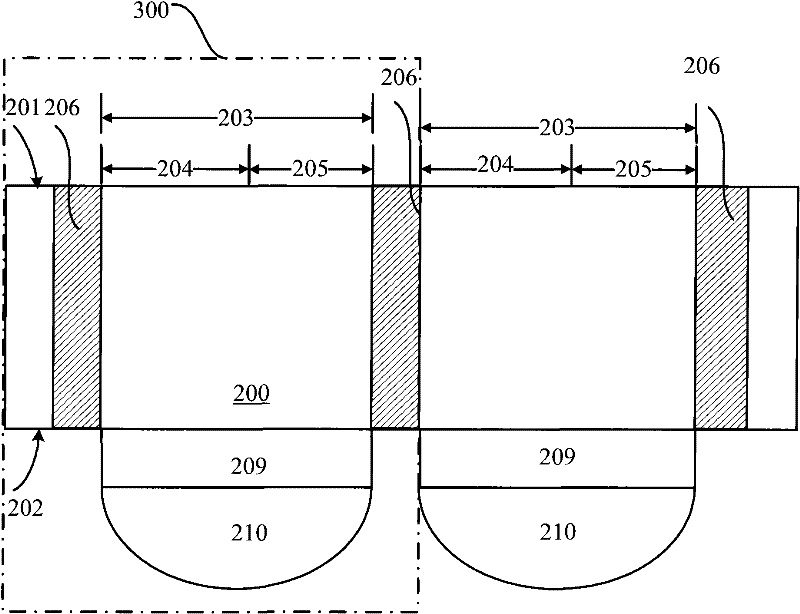

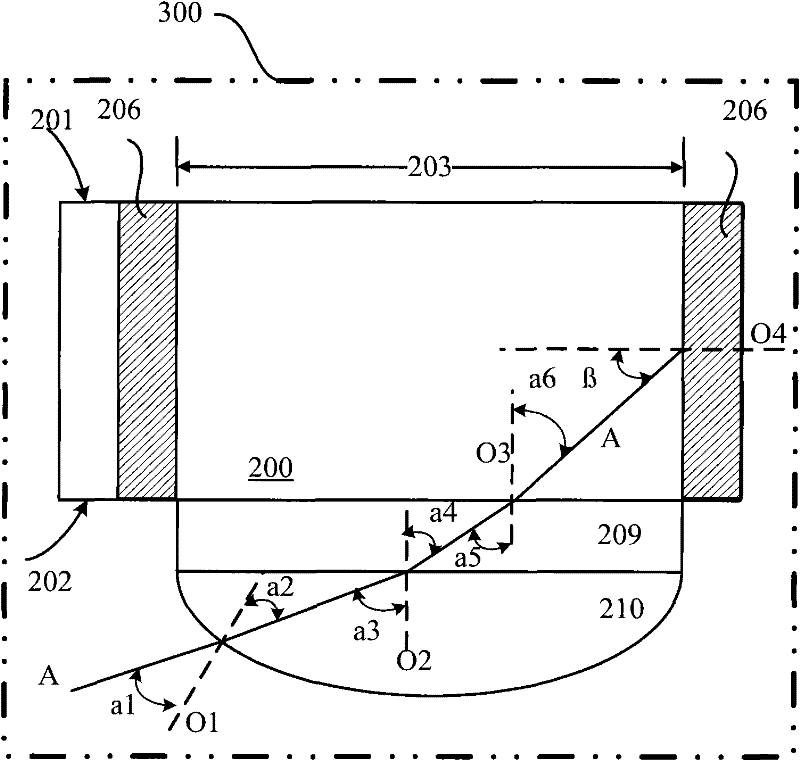

[0039] Existing backside illuminated (Backside illuminated) CMOS image sensors have the problem of display fading. The inventors found that the cause of fading is the crosstalk between adjacent pixels. One of the reasons for the crosstalk is that the existing shallow trench isolation structure cannot effectively isolate the diffusion of photo-generated carriers between adjacent pixel units. Since the incident light of the back-illuminated CMOS image sensor enters the pixel unit area of the semiconductor substrate through the microlens and the optical filter, in the prior art, in order to improve the effective photosensitive area of the photodiode in the pixel unit area, the depth of the photodiode is usually relatively small. Large, its depth can reach more than 10,000 angstroms, while the depth of existing shallow trench isolation structures is usually in the range of 2,000 to 5,000 angstroms. During the photoelectric conversion, the photo-generated carriers generated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com