Liquid crystal display device with thin-film transistor on color film and its manufacture method

A thin-film transistor and liquid crystal display technology, which is applied in semiconductor/solid-state device manufacturing, instruments, electrical components, etc., can solve the problems of light transmittance and aperture ratio decrease, and light-transmitting materials do not further increase the transmittance, etc., to achieve improved Transmittance, eliminate poor light leakage and other defects, improve the effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

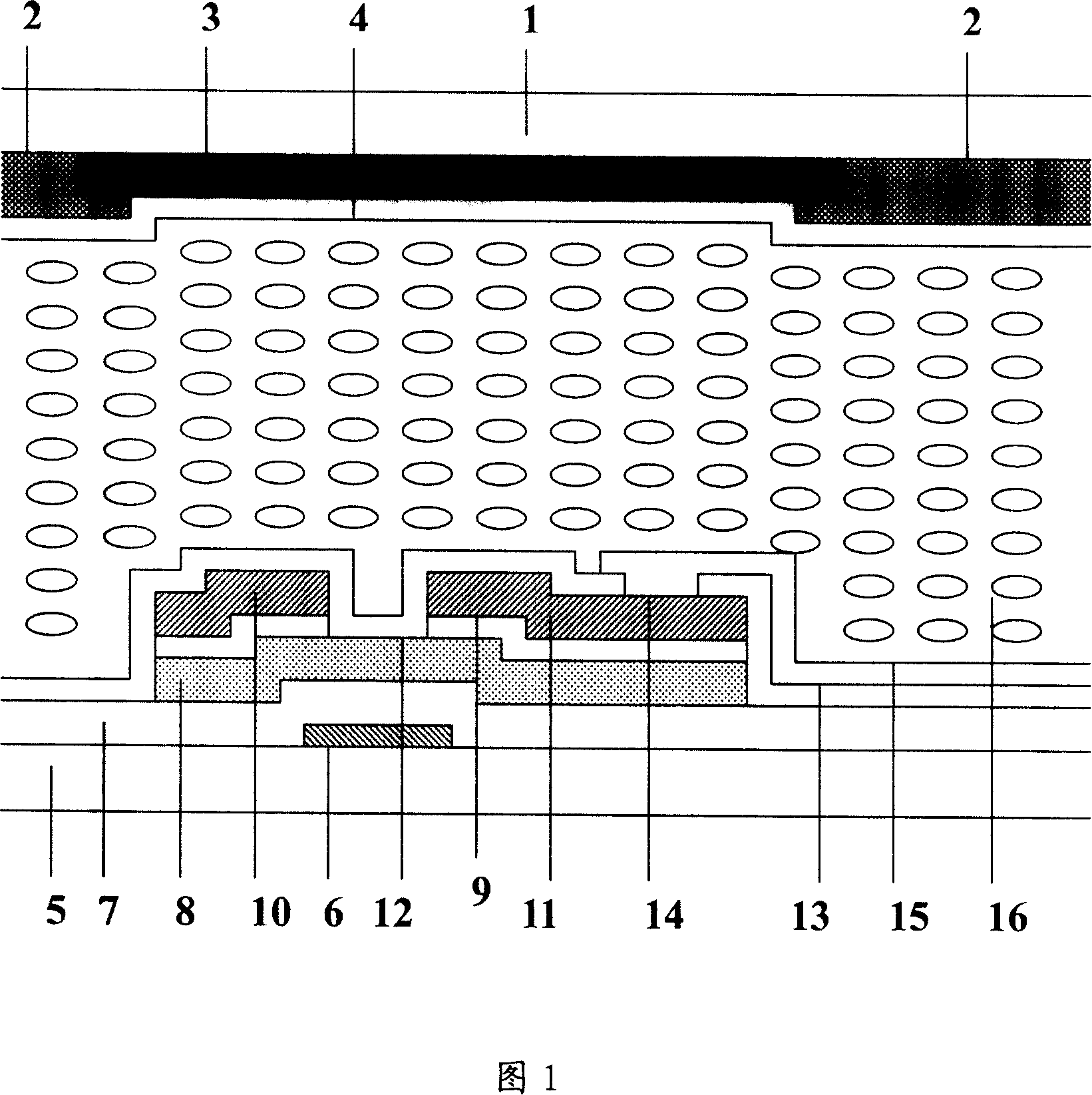

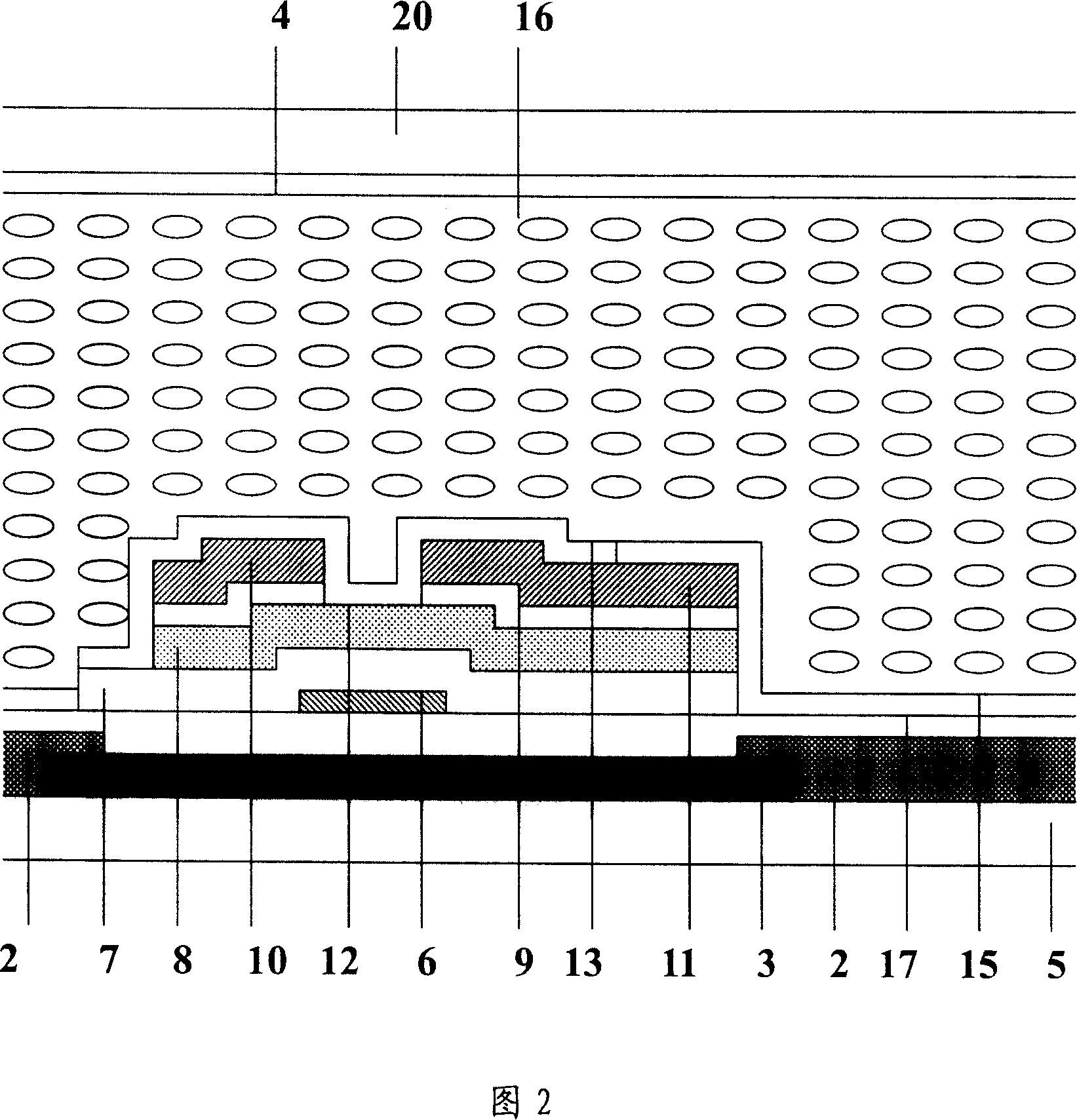

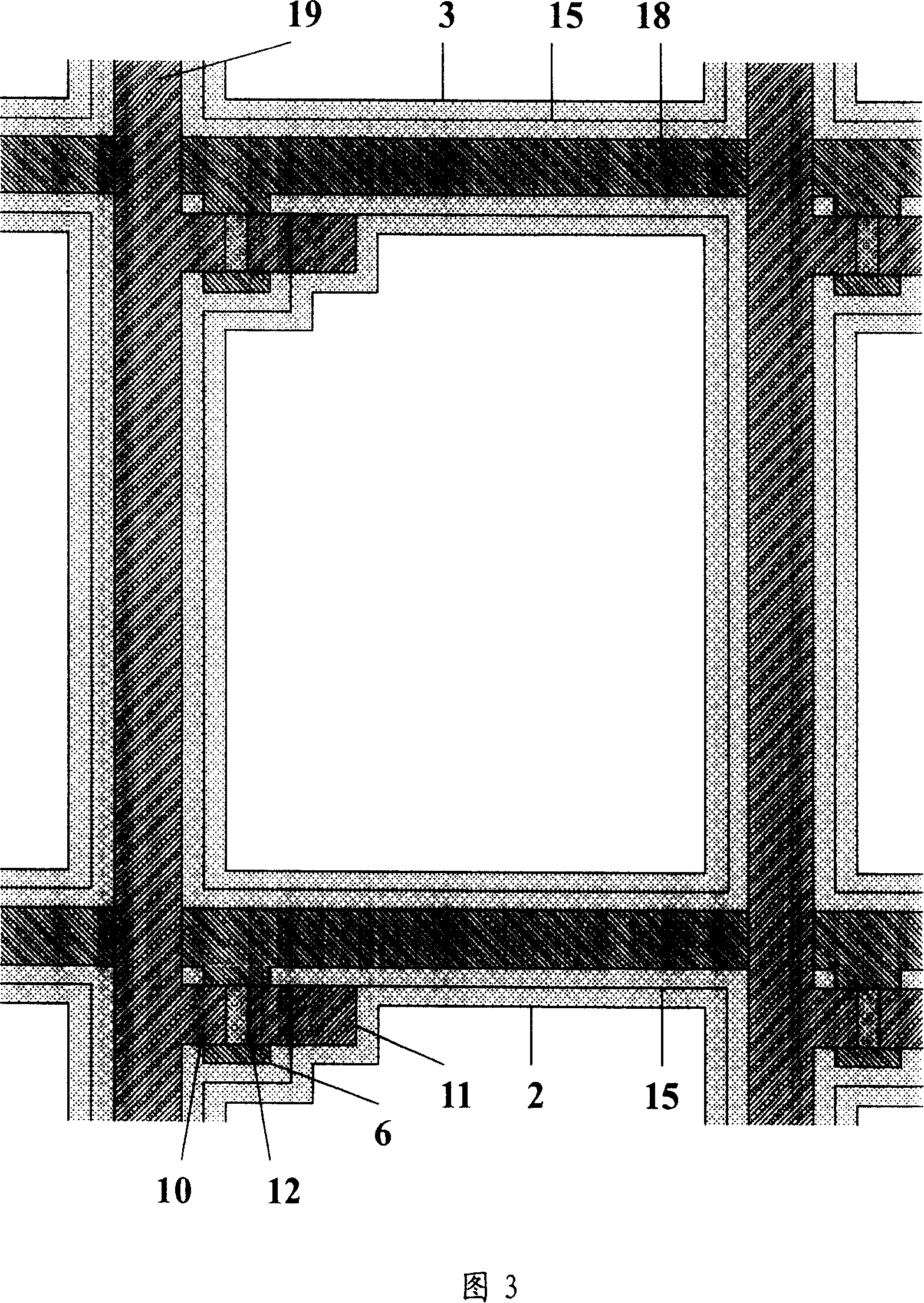

[0049] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be pointed out that the thickness and area size of each layer of films and materials in the drawings do not reflect the real proportion of the device structure, but are only for clearly illustrating the content of the present invention.

[0050] The liquid crystal display device of the present invention comprises an array substrate and a common electrode substrate, liquid crystal molecules sandwiched between them, peripheral circuits and driving circuit boards, and a backlight source. The difference from traditional liquid crystal display devices is that the color filter layer and black matrix are formed on the glass of the array substrate, and the thin film transistor is formed on the color filter composed of the color filter layer and black matrix; the other glass substrate is only transparent Common electrode made of conductive film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com