Isothermal forming die of large-curvature titanium alloy covering part and forming method of isothermal forming die

A technology for skin parts and forming molds, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult materials, difficult flow of sheets, serious problems, etc., to save process steps, improve product processing quality, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

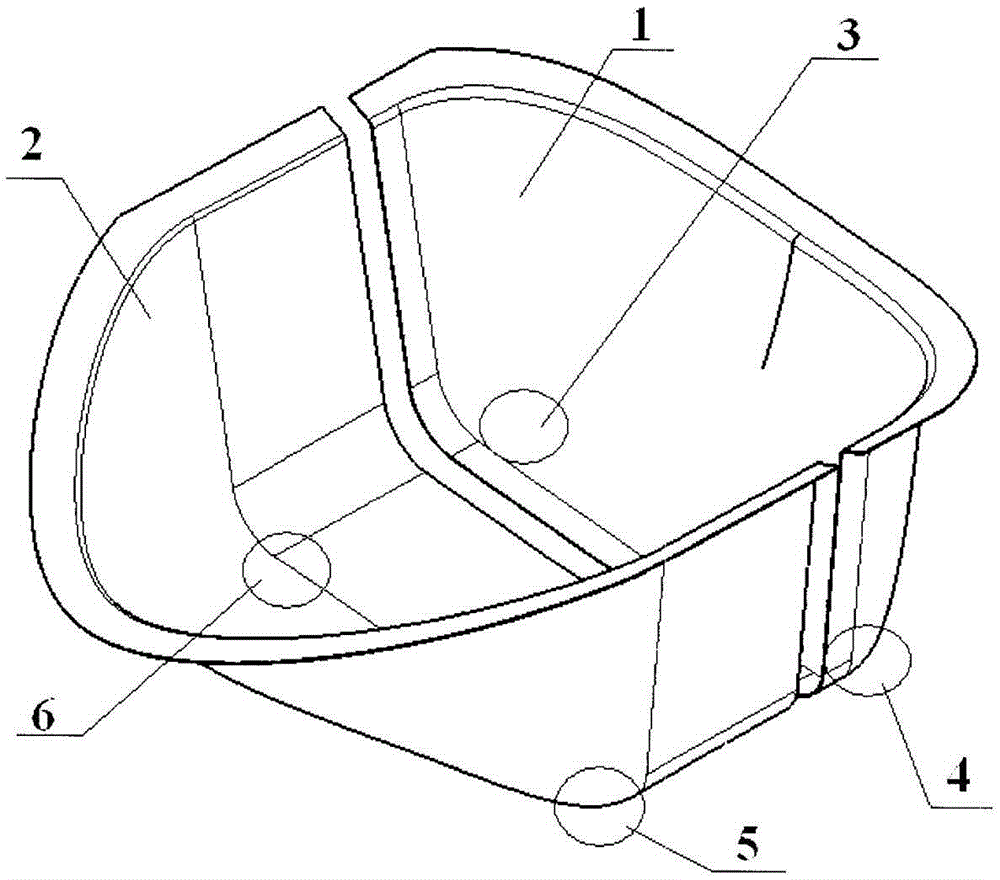

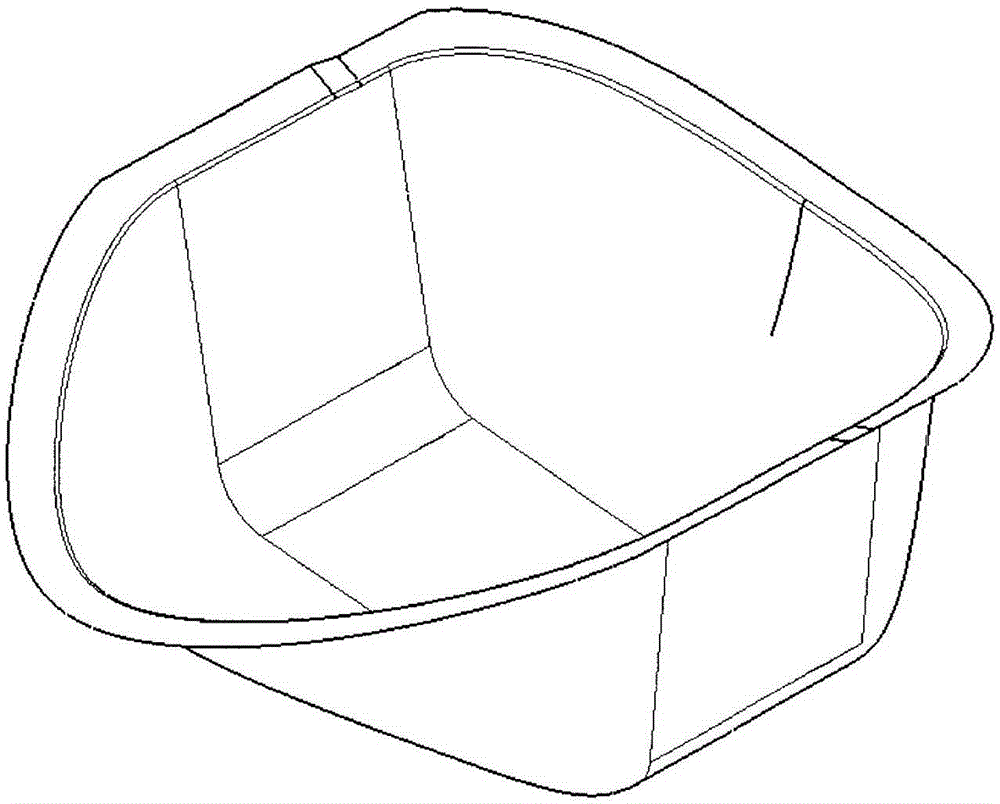

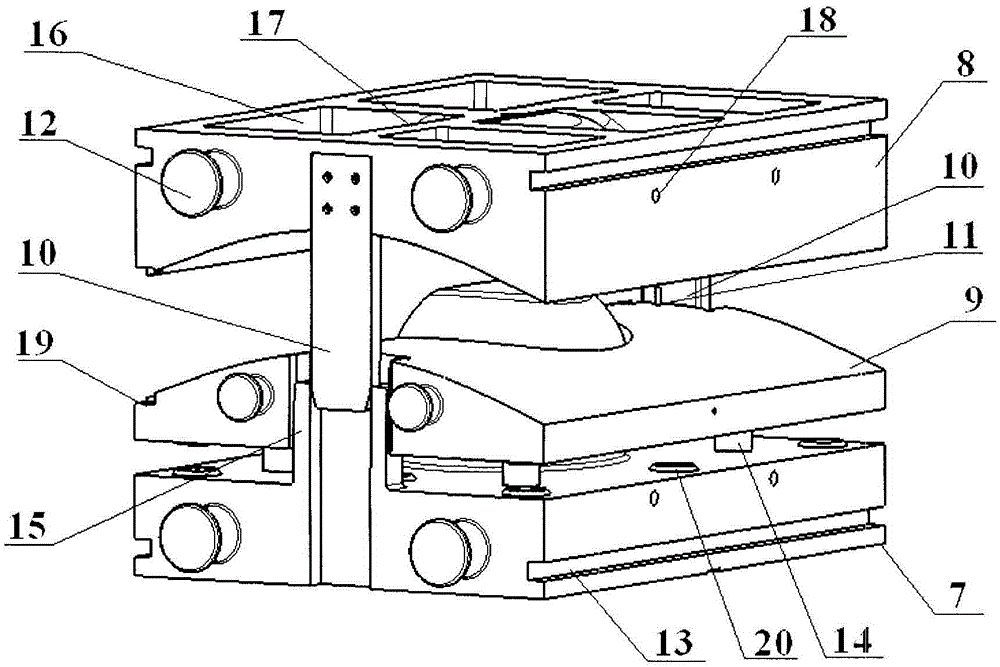

[0028] like image 3 As shown, a large-curvature titanium alloy skin parts isothermal forming die is used for isothermal thermoforming of skin parts, and a blank holder 9 is provided between the punch 7 and the die 8, and the blank holder 9 The lower surface is matched with the surface of the punch 7, and the upper surface is matched with the lower surface of the die 8; the bottom surface of the blank holder 9 is connected with the upper surface of the punch 7 through the ejector rod 4, and the side of the blank holder 9 is provided with a limit groove , is slidingly connected with the outer edge of the guide structure 15 on the punch 7; the upper surface of the blank holder 9 is attached to the lower surface of the die 8, and the side end of the die 8 is provided with a guide plate 10, and the guide plate 10 is connected to the The inner edge groove of the guide structure 15 is slidingly connected; the upper surface of the blank holder 9 is provided with a cylindrical pin 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com