Lithium ion battery adopting lithium-rich manganese-based material as positive electrode and preparation method of lithium ion battery

A lithium-ion battery, lithium-rich manganese-based technology, used in nanotechnology for materials and surface science, secondary batteries, battery electrodes, etc., can solve problems such as low energy density, achieve high energy density, and improve porosity. , the effect of enhancing the embedding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention provides a method for preparing a lithium-ion battery using a lithium-rich manganese-based material as a positive electrode, comprising the following steps:

[0050] The preparation of positive electrode slurry and negative electrode slurry includes the following steps: adding 80-95% (weight ratio) of positive electrode active material, 3-18% (weight ratio) of conductive agent, and 2-17% (weight ratio) of binder In an organic solvent, after high-speed stirring, it is configured into a positive electrode slurry; 80-95% (weight ratio) of the negative electrode active material, 3-18% (weight ratio) of the conductive agent, and 2-17% (weight ratio) of the binder are respectively Add organic solvent or deionized water, after high-speed stirring, prepare negative electrode slurry;

[0051] The preparation of the positive electrode surface coating slurry includes the following steps: add 85-97% (weight ratio) of nanomaterials and 3-15% (weight ratio) of binders t...

Embodiment 1

[0058] (1) Preparation of positive and negative electrode slurries: 93% (weight ratio) of lithium-rich manganese-based materials, 4% (weight ratio) of conductive carbon black, and 3% (weight ratio) of PVDF were added to NMP, respectively. After high-speed stirring, uniformly mix into positive electrode slurry; 93% (weight ratio) of artificial graphite, 3% (weight ratio) of conductive carbon black, 1.5% (weight ratio) of CMC and 2.5% (weight ratio) of SBR are respectively Add it into deionized water, and mix it evenly to form negative electrode slurry after high-speed stirring.

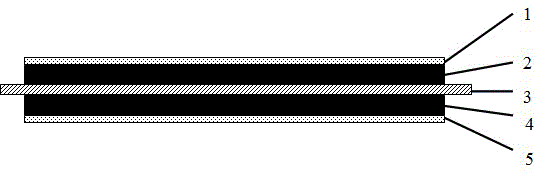

[0059] (2) Preparation of positive pole piece and negative pole piece: refer to figure 1 , the prepared positive electrode slurry 2 and positive electrode slurry 4 were uniformly coated on both sides of the aluminum foil 3 by a coating machine, and the surface density of one side was 18.5 mg / cm 2, after drying and rolling, the positive electrode sheet is obtained. Surface coating slurry 1 and surface...

Embodiment 2

[0077] (1) Preparation of positive and negative electrode slurries: 95% (weight ratio) of lithium-rich manganese-based materials, 3% (weight ratio) of conductive carbon black, and 2% (weight ratio) of PVDF were added to NMP, and the After high-speed stirring, uniformly mix into positive electrode slurry; 95% (by weight) of artificial graphite, 3% (by weight) of conductive carbon black, 0.5% (by weight) of CMC and 1.5% (by weight) of SBR Add it into deionized water, and mix it evenly to form negative electrode slurry after high-speed stirring.

[0078] (2) Preparation of positive electrode sheet and negative electrode sheet: The prepared positive electrode slurry is evenly coated on both sides of the aluminum foil by a coating machine, and the density of one side is 18.5 mg / cm 2 , after drying and rolling, the positive electrode sheet is obtained. A slurry containing 97% (weight ratio) of nano-alumina and 3% (weight ratio) of a binder is evenly coated on the rolled positive el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com