Ethylene-vinyl acetate copolymer packaging thin film

A vinyl acetate, packaging film technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of increasing energy consumption of solar cell modules, reducing production efficiency, slow decomposition speed, etc., to reduce crosslinking agent residues, improve Production efficiency, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

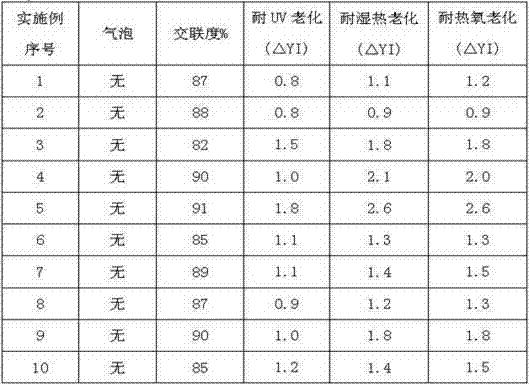

Examples

Embodiment 1

[0030] The ratio of raw materials of the present invention is calculated in the following parts by weight.

[0031] Ethylene-vinyl acetate copolymer-100 parts, the vinyl acetate content in the ethylene-vinyl acetate copolymer is 25%;

[0032] Crosslinking agent: ortho-tert-butyl-o-(2-ethylhexyl) monoperoxycarbonate-0.1 part;

[0033] Auxiliary cross-linking agent: triallyl isocyanurate-0.1 part, the combination of triallyl isocyanurate and o-tert-butyl-o-(2-ethylhexyl) monoperoxycarbonate The ratio is 1:1;

[0034] Antioxidant: tetrakis (β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester-0.1 part;

[0035] Ultraviolet light absorber: 2-hydroxy-4-methoxybenzophenone-0.1 part;

[0036] Light stabilizer: bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate - 0.1 part;

[0037] Tackifier: γ-methacryloxypropyltrimethoxysilane - 0.4 parts.

[0038] Mix the above components evenly, and extrude the mixture through the extruder after blending, the temperature is co...

Embodiment 2

[0040] The ratio of raw materials of the present invention is calculated in the following parts by weight.

[0041] Ethylene-vinyl acetate copolymer-100 parts, the vinyl acetate content in the ethylene-vinyl acetate copolymer is 25%;

[0042]Crosslinking agent: 2,5-dimethylhexane-2,5-di-tert-butyl peroxide-1.0 parts;

[0043] Auxiliary cross-linking agent: triallyl cyanurate-0.2 parts, the ratio of triallyl cyanurate to 2,5-dimethylhexane-2,5-di-tert-butyl peroxide 1:5;

[0044] Antioxidant: β-(4-hydroxyphenyl-3,5-di-tert-butyl) n-octadecyl propionate-0.5 part, 2,6-di-tert-butyl-4-methylphenol-0.5 share;

[0045] Ultraviolet light absorber: 2-hydroxyl-4-n-octyloxybenzophenone-0.3 parts;

[0046] Light stabilizer: bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate - 0.2 parts;

[0047] Tackifier: γ-methacryloxypropyltrimethoxysilane - 0.5 parts.

[0048] The preparation method is the same as in Example 1.

Embodiment 3

[0050] The ratio of raw materials of the present invention is calculated in the following parts by weight.

[0051] Ethylene-vinyl acetate copolymer-100 parts, the vinyl acetate content in the ethylene-vinyl acetate copolymer is 28%;

[0052] Crosslinking agent: 1,1-bis(tert-butyl peroxide)-3,3,5-trimethylcyclohexane-1.0 parts;

[0053] Auxiliary cross-linking agent: triallyl isocyanurate - 10.0 parts, triallyl isocyanurate and 1,1-di(tert-butyl peroxide)-3,3,5-trimethyl The ratio of cyclohexane is 10:1;

[0054] Antioxidant: β-(4-hydroxyphenyl-3,5-di-tert-butyl) n-octadecyl propionate-0.2 parts, 2,6-di-tert-butyl-4-methylphenol-0.3 share;

[0055] UV absorber: 2-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole-0.2 parts;

[0056] Light stabilizer: bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate - 0.4 parts;

[0057] Tackifier: γ-methacryloxypropyltrimethoxysilane - 1.0 parts.

[0058] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com