High-compaction-density positive electrode material and electrochemical energy storage device

A positive electrode material and chemical formula technology, applied in the field of high compaction density positive electrode materials and electrochemical energy storage devices, can solve the problems of low gram capacity, low energy density of positive electrode materials, serious gas production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

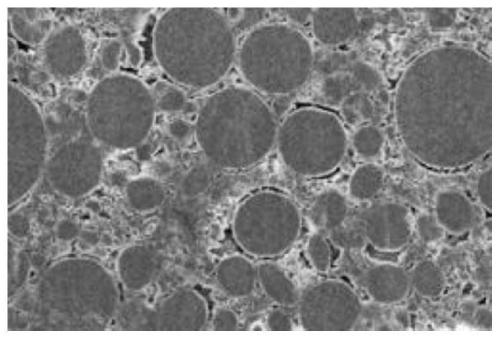

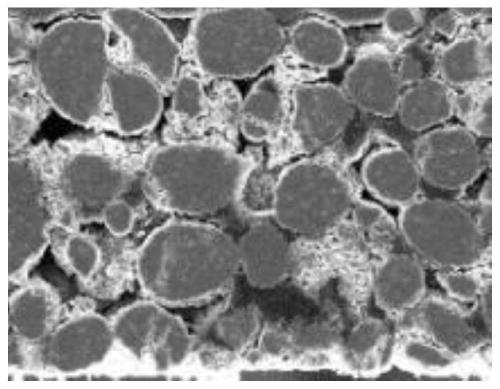

Image

Examples

preparation example Construction

[0052] The second aspect of the present invention provides the preparation method of the cathode material of the first aspect of the present invention, comprising:

[0053] Provide lithium nickel transition metal oxide A;

[0054] Provide lithium nickel transition metal oxide B;

[0055] Lithium nickel transition metal oxide A and lithium nickel transition metal oxide B were mixed.

[0056]In the preparation method of the positive electrode material provided by the present invention, the lithium nickel transition metal oxide A and / or the lithium nickel transition metal oxide B can be surface-modified, for example, the lithium nickel transition metal oxide A and / or Or lithium nickel transition metal oxide B is respectively surface modified, and then mixed, wherein the surface modification methods of lithium nickel transition metal oxide A and lithium nickel transition metal oxide B can be the same or different; lithium nickel can also be The transition metal oxide A and the l...

Embodiment 1

[0075] 1. Preparation of cathode materials

[0076] 1) Preparation of the precursors of lithium-nickel transition metal oxides A and B: nickel sulfate, manganese sulfate, and cobalt sulfate were prepared in a molar ratio into a 1mol / L solution, and a large particle size of 10 μm was prepared by hydroxide co-precipitation technology. Precursor of granular lithium nickel transition metal oxide A; nickel sulfate, manganese sulfate, and cobalt sulfate are configured into a 1mol / L solution in molar ratio, and a small particle lithium nickel transition metal with a particle size of 3 μm is prepared by hydroxide co-precipitation technology Precursor of oxide B. In the process of preparing the precursor, the particle size can be controlled by controlling the reaction time, pH value during co-precipitation, and ammonia concentration;

[0077] 2) Lithium nickel transition metal oxide A (polycrystalline LiNi 0.8 co 0.1 mn 0.1 o 2 ) preparation method:

[0078] The precursor Ni of t...

Embodiment 2

[0097] Compared with Example 1, the difference lies in the preparation method of the positive electrode material: the precursor particle size of the lithium nickel transition metal oxide B is 4 μm, the surface modified lithium nickel transition metal oxide A and the surface modified lithium nickel transition metal The mass ratio of oxide B is 7:3.

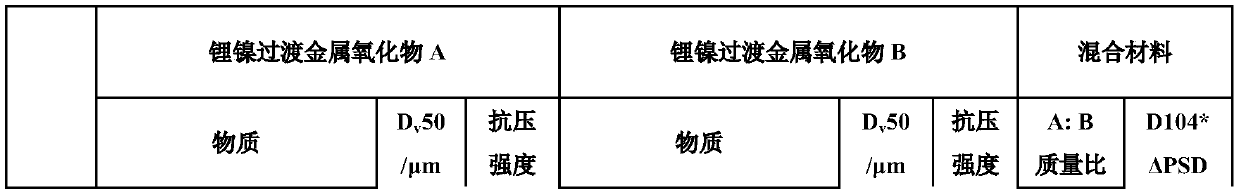

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com