Process for producing cupric hydroxide or cupric oxide

A technology of copper hydroxide and copper oxide, applied in copper oxide/copper hydroxide and other directions, can solve the problems of inability to formulate, production technology can not reach the purity, can not meet the needs of the market, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The method for preparing copper hydroxide of the present invention will be further described in detail below in conjunction with specific examples.

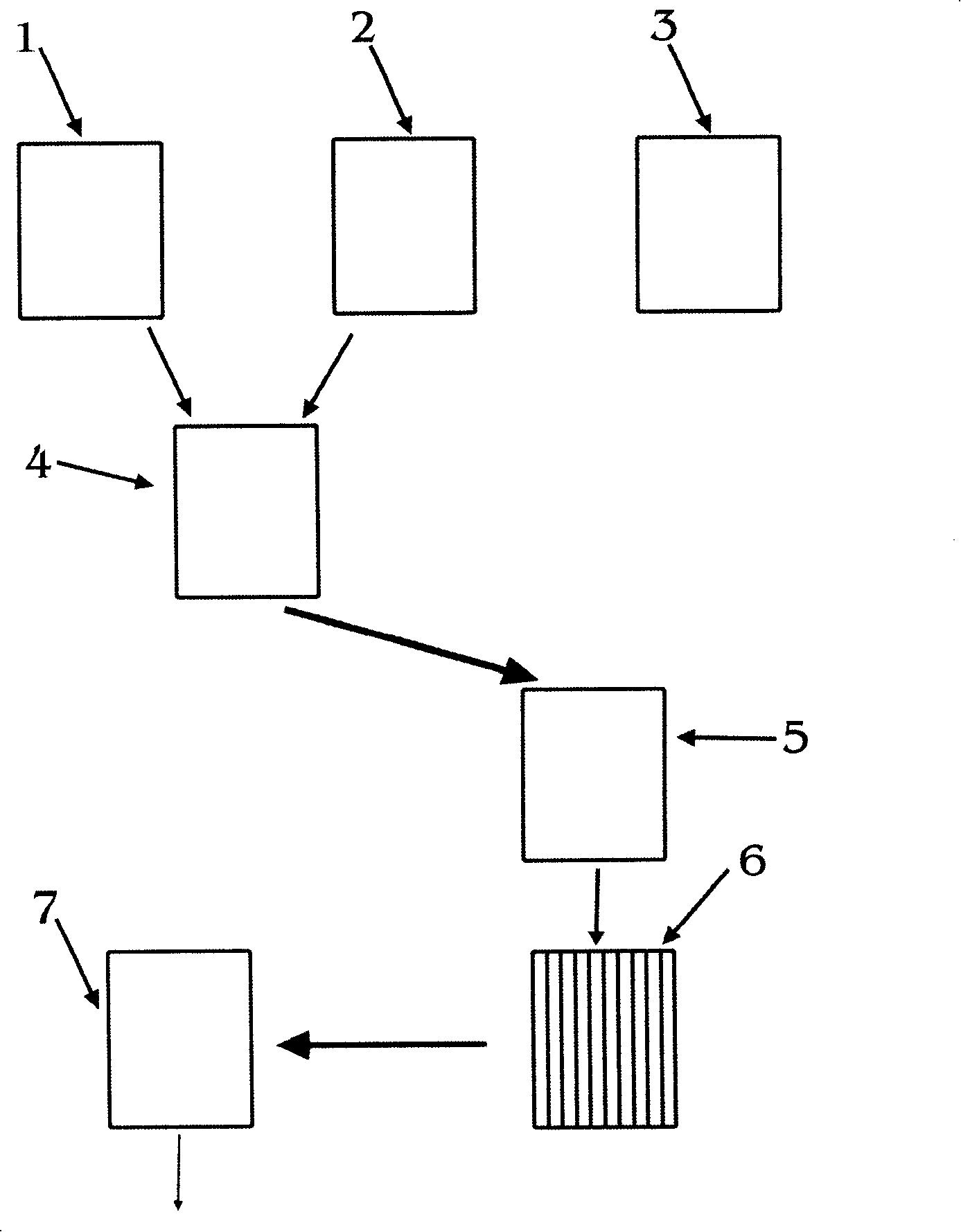

[0008] Such as figure 1 As shown, the soluble copper-containing solution of copper nitrate, copper sulfate or copper chloride produced in the production of circuit boards with 1-30% copper is filtered and placed in container 1, and the copper-containing 1-30% alkaline chlorination Cuprocopper ammonium ion or the sodium hydroxide solution that is 1~45% is placed in the container 2 after filtering, and in the reactor 4, the solution in the two containers is added under stirring situation simultaneously,

[0009] When the pH in the solvent is controlled at 4.5-9 and the volume of the solution in the reactor 4 rises to more than 2000L, start to open the discharge valve at the lower outlet of the reactor 4 while feeding and reacting, and turn on the pressure filter pump for pressure filtration or centrifuge Centrifuge, wash wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com