Novel formaldehyde scavenging material for urea formaldehyde resin glue, and preparation and application methods thereof

A technology for urea-formaldehyde resin glue and formaldehyde capture, which is applied in the direction of non-polymer adhesive additives, adhesive additives, polymer adhesive additives, etc., can solve the problems of reducing the mechanical properties of the board, low capture efficiency, etc., and achieve formaldehyde absorption Increased efficiency, high aldehyde removal rate, and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

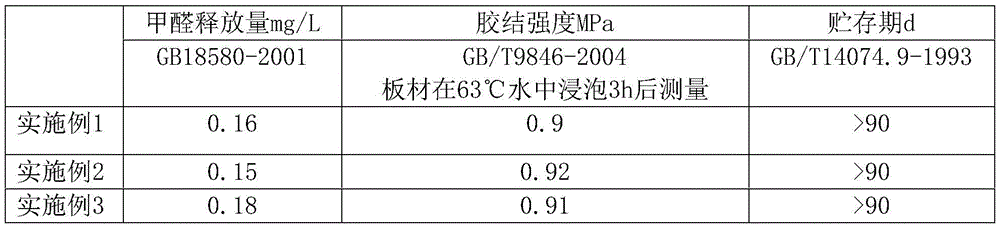

Examples

Embodiment 1

[0026] A new formaldehyde capture material for urea-formaldehyde resin glue, its raw material components include: 30 parts of phosphoric acid, 25 parts of urea, 2 parts of triethanolamine, 15 parts of water, 0.01 part of sodium edetate, 3 parts of ammonium phosphate, 10 parts of glycerol, 15 parts of ethyl 3-oxobutyrate, 2 parts of melamine, 1 part of ethylene glycol, 0.5 parts of alkylphenol polyoxyethylene ether, 3 parts of phenol, 2 parts of ethanol, 1 part of ferric chloride , 1 part of copper hydroxide, 0.3 part of diatomaceous earth, 0.2 part of rosin methyl ester and 0.5 part of aluminum oxide, the parts are parts by mass.

[0027] The preparation method of the above-mentioned formaldehyde capture new material for urea-formaldehyde resin glue comprises the following steps connected in sequence:

[0028] a. React phosphoric acid, urea, water, triethanolamine and sodium edetate at 110-115°C for 3 hours;

[0029] b. React ammonium phosphate, glycerol and ethyl 3-oxobutyra...

Embodiment 2

[0034] A new formaldehyde capture material for urea-formaldehyde resin glue, its raw material components include: 32.4 parts of phosphoric acid, 28 parts of urea, 3 parts of triethanolamine, 18 parts of water, 0.02 parts of sodium edetate, 4 parts of ammonium phosphate, 12 parts of glycerol, 18 parts of ethyl 3-oxobutyrate, 3 parts of melamine, 2 parts of ethylene glycol, 0.8 parts of alkylphenol polyoxyethylene ether, 4 parts of phenol, 3 parts of ethanol, 2 parts of ferric chloride , 1.5 parts of copper hydroxide, 0.4 parts of diatomaceous earth, 0.3 parts of rosin methyl ester and 0.6 parts of aluminum oxide, the parts are parts by mass.

[0035] The preparation method of the above-mentioned formaldehyde capture new material for urea-formaldehyde resin glue comprises the following steps connected in sequence:

[0036] a. React phosphoric acid, urea, water, triethanolamine and sodium edetate at 110-115°C for 3.2 hours;

[0037] b. React ammonium phosphate, glycerol and ethy...

Embodiment 3

[0042] A new formaldehyde capture material for urea-formaldehyde resin glue, its raw material components include: 36 parts of phosphoric acid, 30 parts of urea, 4 parts of triethanolamine, 20 parts of water, 0.03 parts of sodium edetate, 5 parts of ammonium phosphate, 15 parts of glycerol, 20 parts of ethyl 3-oxobutyrate, 5 parts of melamine, 3 parts of ethylene glycol, 1 part of alkylphenol polyoxyethylene ether, 5 parts of phenol, 4 parts of ethanol, 3 parts of ferric chloride , 2 parts of copper hydroxide, 0.5 part of diatomaceous earth, 0.5 part of rosin methyl ester and 0.8 part of aluminum oxide, the parts are parts by mass.

[0043] The preparation method of the above-mentioned formaldehyde capture new material for urea-formaldehyde resin glue comprises the following steps connected in sequence:

[0044] a. React phosphoric acid, urea, water, triethanolamine and sodium edetate at 110-115°C for 3.5 hours;

[0045] b. React ammonium phosphate, glycerol and ethyl 3-oxobut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com