Method for preparing one-dimensional cuprous oxide/carbon nanocomposite catalyst and application

A carbon nanocomposite, cuprous oxide technology, applied in catalyst activation/preparation, organic compound preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as difficult control and high cost, and achieve crystallization The effect of high density, uniform particle distribution and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

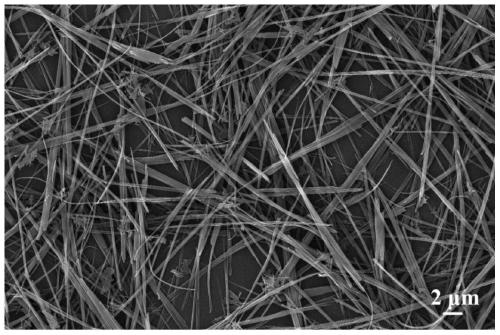

[0028] 1) Make 100mL concentration 0.2mol L -1 The copper nitrate aqueous solution with 150mL concentration is 0.15mol L -1 The sodium salicylate solution was mixed evenly, and after stirring, slowly added 0.5mol·L -1 After adjusting the pH of the system to 7, react in a nitrogen atmosphere at 90°C for 36 hours. The product is centrifuged, washed and dried to obtain a one-dimensional salicylate intercalated layered copper hydroxide precursor. The scanning electron microscope photo is shown in figure 1 ;

[0029] 2) After the precursor prepared in the above steps was calcined at 400° C. for 30 min in a nitrogen atmosphere, a one-dimensional Cu / C nanocomposite material was obtained.

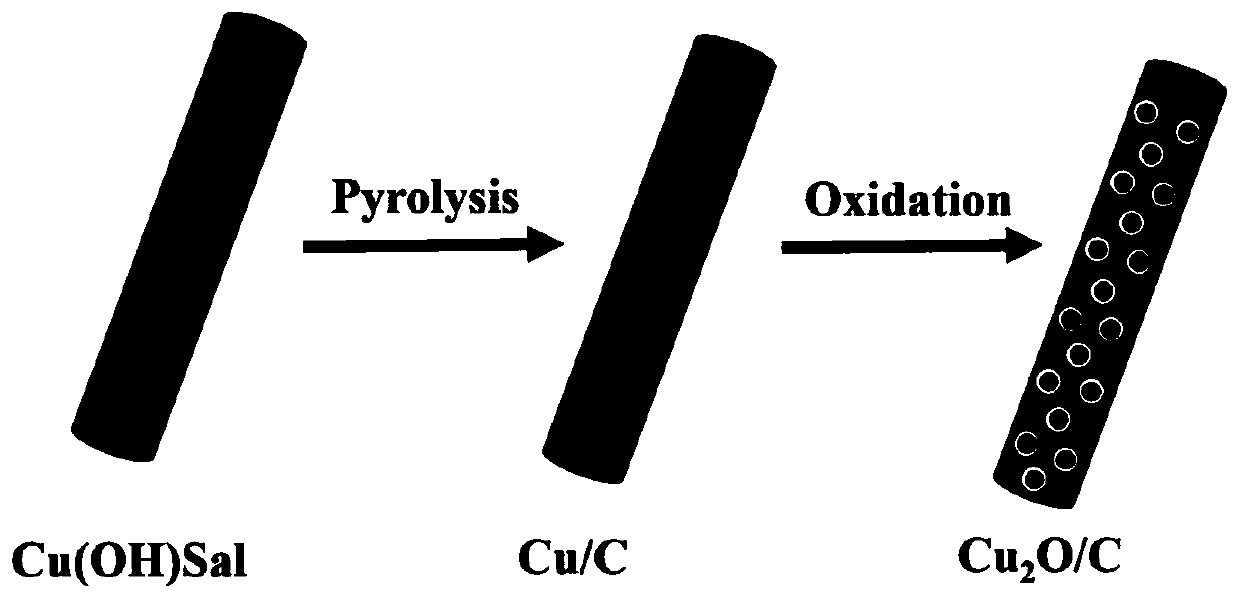

[0030] 3) The one-dimensional Cu / C nanocomposite material prepared in step 2) was placed in an oxygen atmosphere and calcined at 100°C for 30 minutes to obtain a cuprous oxide / carbon nanocomposite catalyst, denoted as catalyst Cu 2 O / C-1, the schematic diagram of the preparation process is shown...

Embodiment 2

[0033] 1) Make 100mL concentration 0.2mol L -1 The cupric chloride solution with 150mL concentration is 0.26mol L -1 The aqueous solution of sodium salicylate was evenly mixed, and after stirring, slowly added 0.5mol·L -1 After adjusting the pH of the system to 6.5, react in an argon atmosphere at 80°C for 48 hours, the product is centrifuged, washed and dried to obtain a one-dimensional salicylate intercalated layered copper hydroxide precursor;

[0034] 2) After the precursor prepared in the above steps was calcined at 600° C. for 5 min in a nitrogen atmosphere, a one-dimensional Cu / C nanocomposite material was obtained.

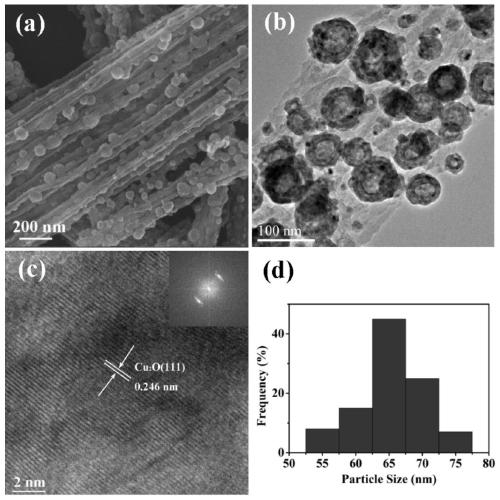

[0035] 3) The nanocomposite prepared in step 2) is placed in an oxygen atmosphere and roasted at 200°C for 0 min to obtain a cuprous oxide / carbon nanocomposite, denoted as catalyst Cu 2 O / C-2, see the characterization results Figure 3-6 .

[0036] The liquid-phase hydrogenation reaction process of p-nitrophenol is as follows: add 2.5mmol L to the quar...

Embodiment 3

[0038] 1) Make 100mL concentration 0.2mol L -1 The concentration of copper sulfate aqueous solution and 150mL is 0.37mol L -1 Potassium salicylate aqueous solution is evenly mixed, after stirring, slowly add 1mol L -1 NaOH aqueous solution, after adjusting the pH of the system to 5.5, reacted in a nitrogen atmosphere at 70°C for 12 hours, and the product was centrifuged, washed and dried to obtain a one-dimensional salicylate intercalated layered copper hydroxide precursor;

[0039] 2) After the precursor prepared in the above steps was calcined at 800° C. for 120 min in an argon atmosphere, a one-dimensional Cu / C nanocomposite material was obtained.

[0040] 3) The nanocomposite prepared in step 2) is placed in an oxygen atmosphere at 300° C. for 5 minutes to obtain a cuprous oxide / carbon nanocomposite, denoted as catalyst Cu 2 O / C-3.

[0041] The liquid-phase hydrogenation reaction process of p-nitrophenol is as follows: add 2.5mmol L to the quartz cuvette in advance -1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com