Preparation method of copper-copper oxide composite electrode

A composite electrode, copper oxide technology, applied in the direction of electrochemical variables of materials, can solve the problems of complex and complicated preparation process, unsatisfactory detection performance, etc., and achieve the effects of low synthesis cost, simple operation, and fully efficient electrocatalytic reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Under room temperature and magnetic stirring conditions, dissolve 0.0858g copper nitrate hydrate in 20ml distilled water (two parts), dissolve 0.04g sodium hydroxide in 20ml distilled water, and mix the two solutions under magnetic stirring to make copper hydroxide turbid liquid. Then the cross-sectional area is 2.5mm 2 , the copper rod with a length of 4 cm was cleaned and treated, and immersed in the above cloudy solution for ultrasonication for 10 minutes.

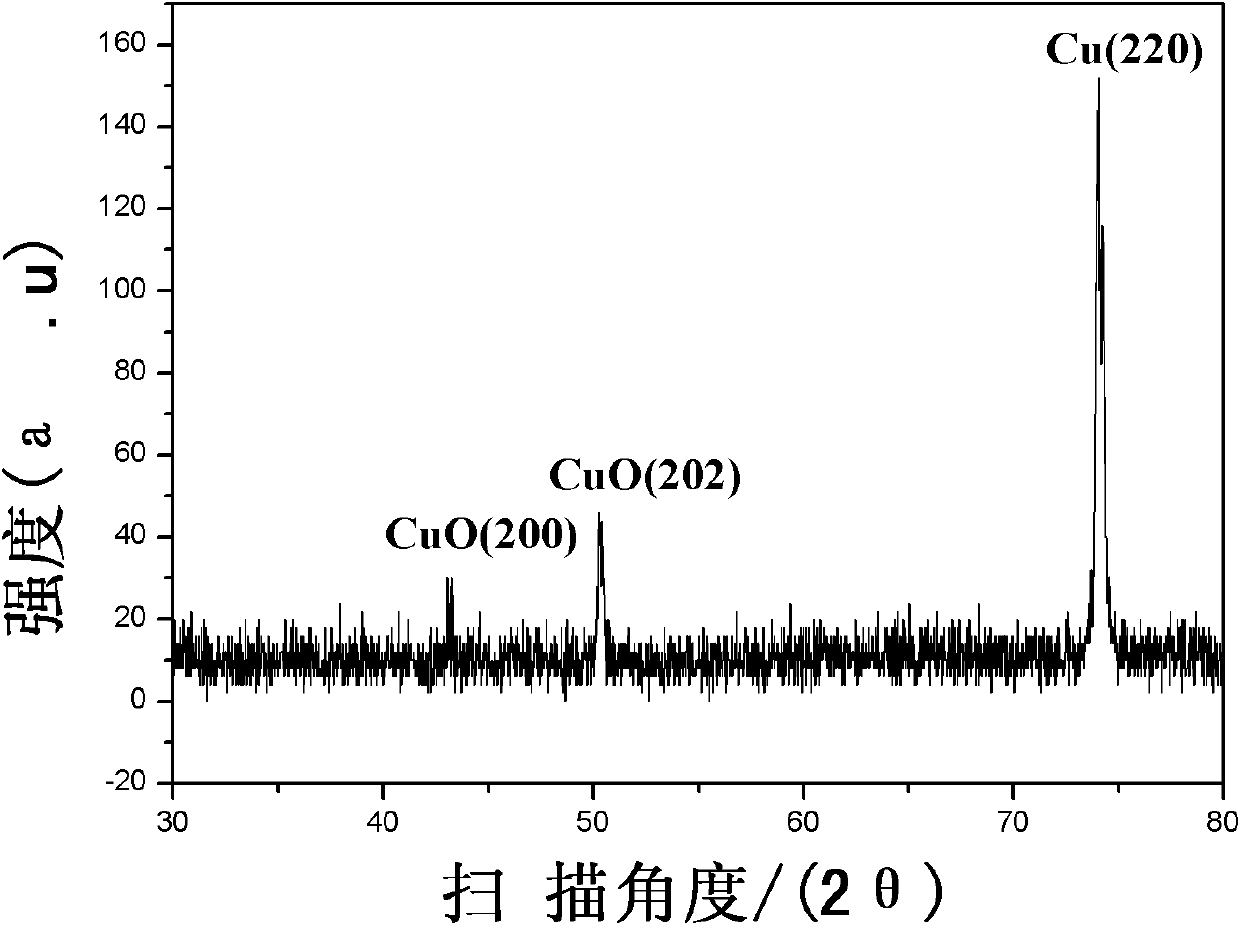

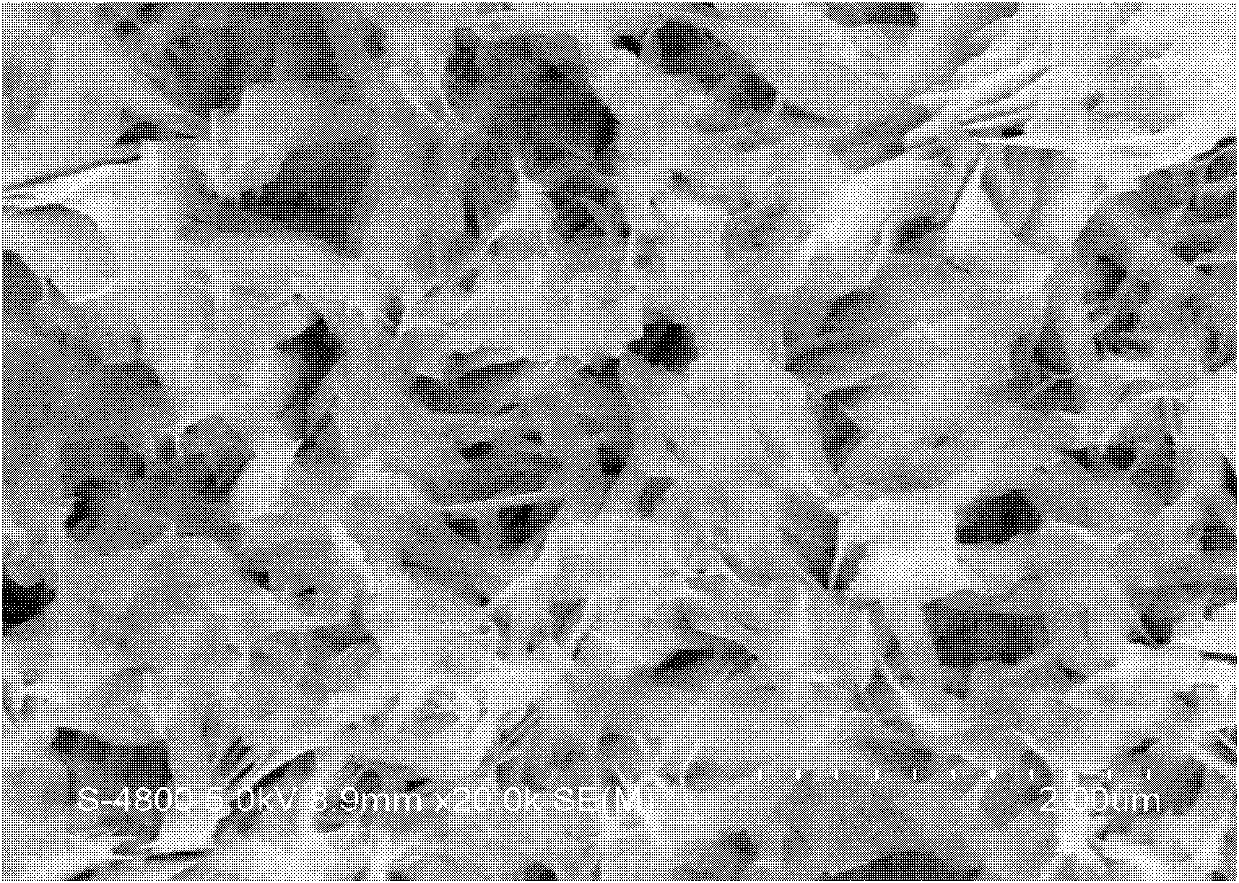

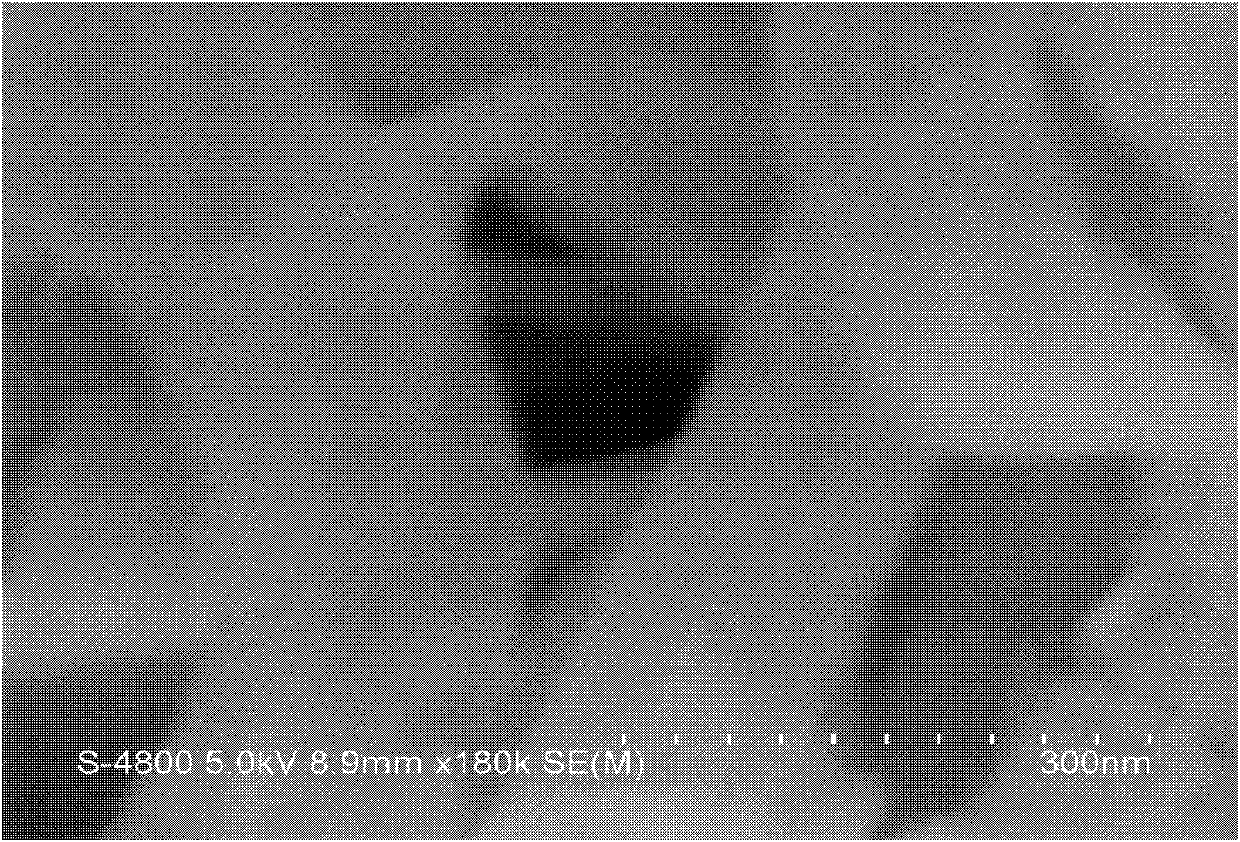

[0040] Transfer a portion of the prepared sodium hydroxide solution to a 60mL reactor, and then transfer the copper rod sonicated in the turbid solution to the reactor. Tighten the lid of the kettle, and react in an oven at 80°C for 4 hours. After the reaction, the kettle was taken out and cooled to room temperature naturally, a layer of black copper oxide was covered on the copper rod, rinsed with distilled water, and the copper rod grown with copper oxide was naturally dried to obtain a copper-copper oxide co...

Embodiment 2

[0044] Under the condition of room temperature and magnetic stirring, dissolve 0.04g sodium hydroxide in 20ml distilled water, and then 2 , the length of the 4cm copper rod is cleaned and processed, and the copper rod is directly put into the sodium hydroxide solution and transferred into the reaction kettle together. Tighten the lid of the kettle, and react in an oven at 80°C for 4 hours. After the reaction, the kettle was taken out and cooled to room temperature naturally, a layer of black copper oxide was covered on the copper rod, rinsed with distilled water, and the copper rod with copper oxide was naturally dried to obtain a copper-copper oxide composite electrode. The surface of the resulting composite electrode is only slightly covered with a layer of copper oxide nanobelts.

Embodiment 3

[0046] Under room temperature and magnetic stirring conditions, dissolve 0.0858g copper nitrate hydrate in 20ml distilled water, dissolve 0.08g sodium hydroxide in 20ml distilled water, and mix the two solutions under magnetic stirring to prepare a copper hydroxide turbid solution. Then the cross-sectional area is 2.5mm 2 , the copper rod with a length of 4 cm was cleaned and treated, and immersed in the above cloudy solution for ultrasonication for 10 minutes.

[0047] Transfer a portion of the prepared sodium hydroxide solution to a 60mL reactor, and then transfer the copper rod sonicated in the turbid solution to the reactor. Tighten the lid of the kettle, and react in an oven at 80°C for 4 hours. After the reaction, the kettle was taken out and cooled to room temperature naturally, a layer of black copper oxide was covered on the copper rod, rinsed with distilled water, and the copper rod grown with copper oxide was naturally dried to obtain a copper-copper oxide composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com