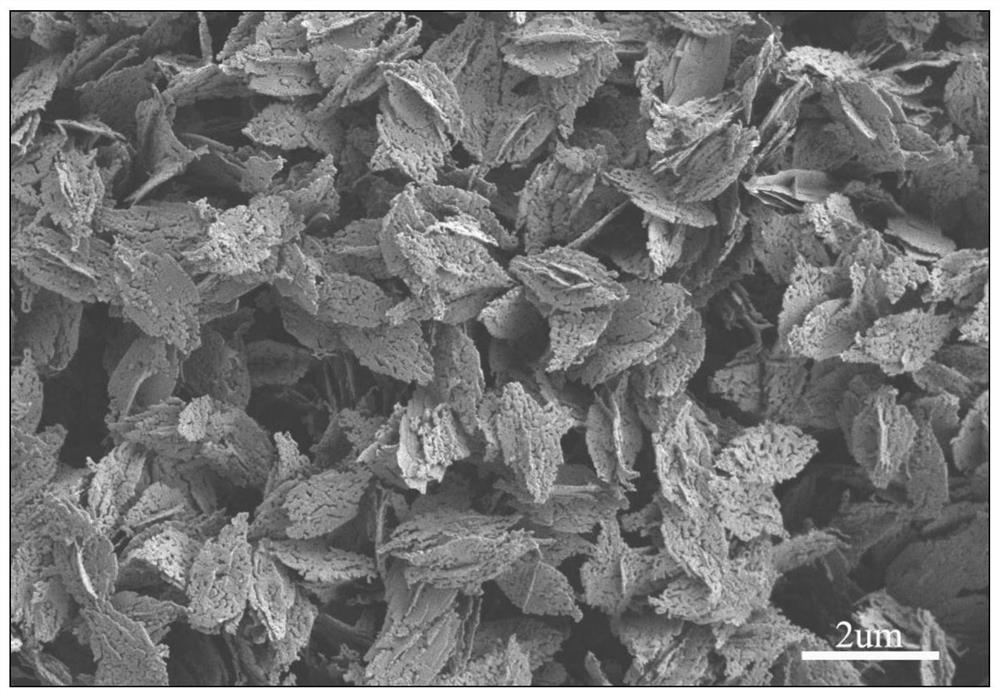

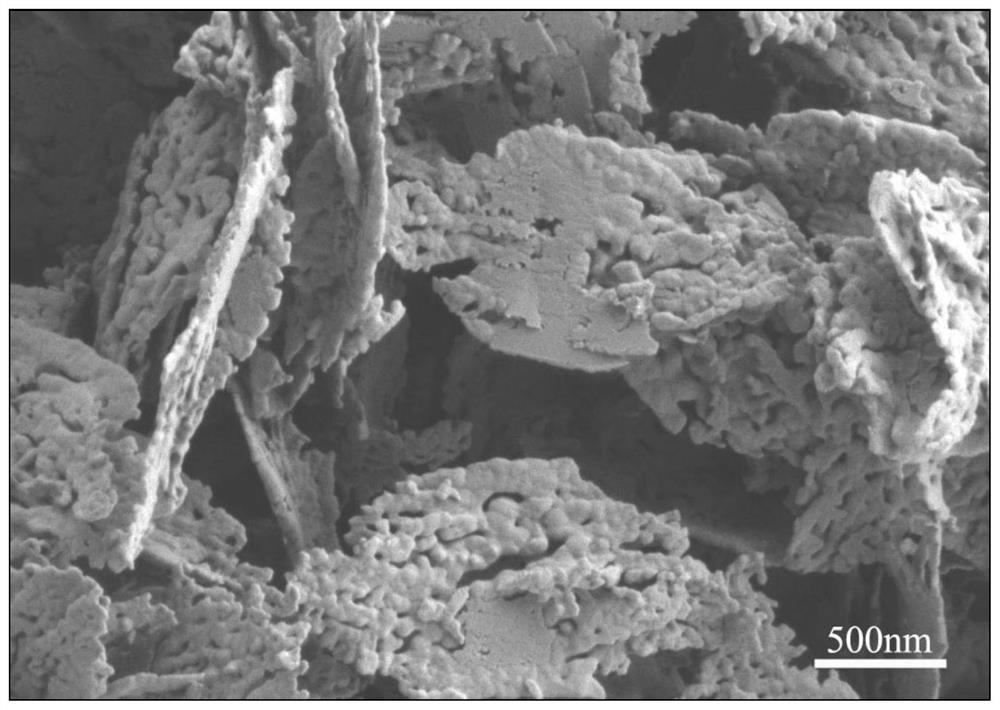

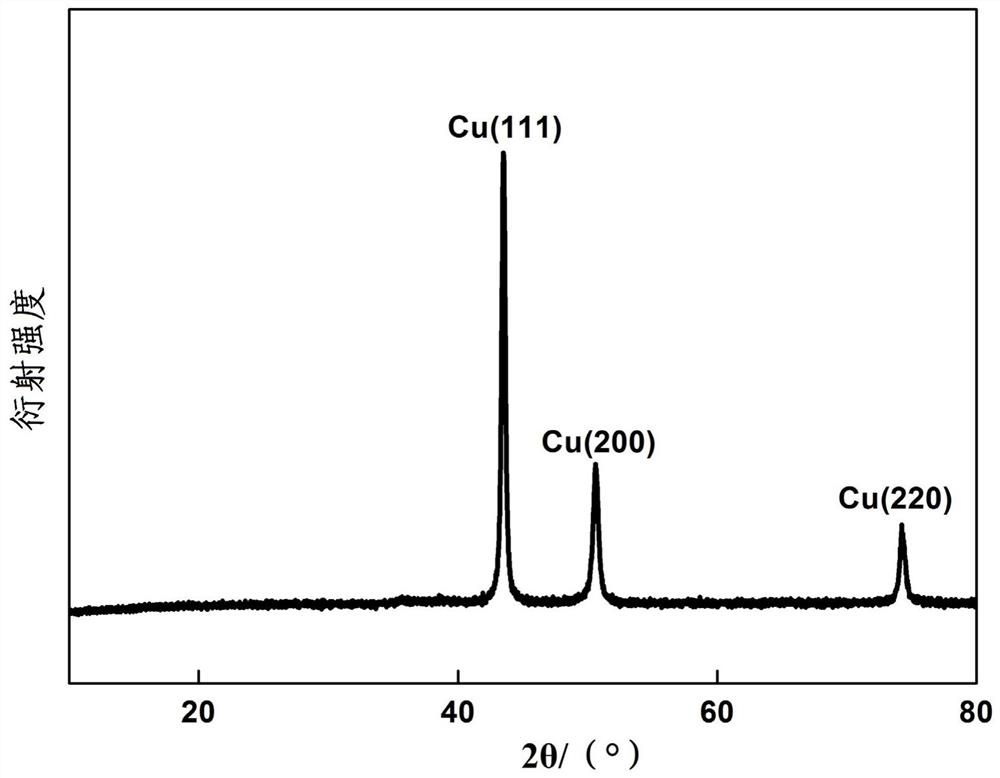

A preparation method of leaf-shaped porous copper nanosheets

A technology of nanosheets and porous copper, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. It can solve problems such as unfavorable performance of flexible electronic products, inconvenient cleaning and purification of copper nanosheets, and increased circuit resistance. , to achieve the effect of good contact, good dispersion and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment includes the following steps:

[0034] Step 1, polyethylene glycol and copper chloride are dissolved in deionized water to obtain a mixed solution; the mass concentration of polyethylene glycol in the mixed solution is 1g / L, and the mass concentration of copper chloride is 1g / L, so The polyethylene glycol is polyethylene glycol 8000; the volume of the mixed solution is 0.5L;

[0035] Step 2, add ammoniacal liquor to the mixed solution obtained in step 1, then stir to obtain a copper-ammonia complex solution; the volume of the added ammoniacal liquor is 0.5mL, and the substance concentration of the ammoniacal liquor is 2mol / L, so The time of stirring is 0.5h;

[0036] Step 3, heating the copper-ammonia complex solution obtained in step 2 in a water bath under stirring conditions, and then adding sodium hydroxide solution dropwise to the copper-ammonia complex solution for reaction to obtain copper oxide nanosheets; the water bath The heating temperature...

Embodiment 2

[0042] This embodiment includes the following steps:

[0043] Step 1, polyethylene glycol and copper chloride are dissolved in deionized water to obtain a mixed solution; the mass concentration of polyethylene glycol in the mixed solution is 4g / L, and the mass concentration of copper chloride is 5g / L, so The polyethylene glycol is polyethylene glycol 8000; the volume of the mixed solution is 1L;

[0044] Step 2, add ammoniacal liquor to the mixed solution obtained in step 1, then stir to obtain a copper-ammonia complex solution; the volume of the added ammoniacal liquor is 1mL, and the substance concentration of the ammoniacal liquor is 2mol / L. The stirring time is 0.6h;

[0045] Step 3, heating the copper-ammonia complex solution obtained in step 2 in a water bath under stirring conditions, and then adding sodium hydroxide solution dropwise to the copper-ammonia complex solution for reaction to obtain copper oxide nanosheets; the water bath The heating temperature is 95°C, ...

Embodiment 3

[0049] This embodiment includes the following steps:

[0050] Step 1, polyethylene glycol and copper chloride are dissolved in deionized water to obtain a mixed solution; the mass concentration of polyethylene glycol in the mixed solution is 1g / L, and the mass concentration of copper chloride is 0.5g / L, The polyethylene glycol is polyethylene glycol 8000; the volume of the mixed solution is 0.1L;

[0051] Step 2, add ammoniacal liquor to the mixed solution obtained in step 1, then stir to obtain a copper-ammonia complex solution; the volume of the added ammoniacal liquor is 0.1mL, and the substance concentration of the ammoniacal liquor is 2mol / L, so The time of stirring is 0.4h;

[0052] Step 3, heating the copper-ammonia complex solution obtained in step 2 in a water bath under stirring conditions, and then adding sodium hydroxide solution dropwise to the copper-ammonia complex solution for reaction to obtain copper oxide nanosheets; the water bath The heating temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com