Copper humate-containing antibacterial and yield-improving composition and preparation method thereof

A technology of copper humate and composition, which is applied in botany equipment and methods, chemicals for biological control, fungicides, etc., and can solve the problems of inability to meet the requirements of planting, low drug release efficiency, poor antibacterial properties, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

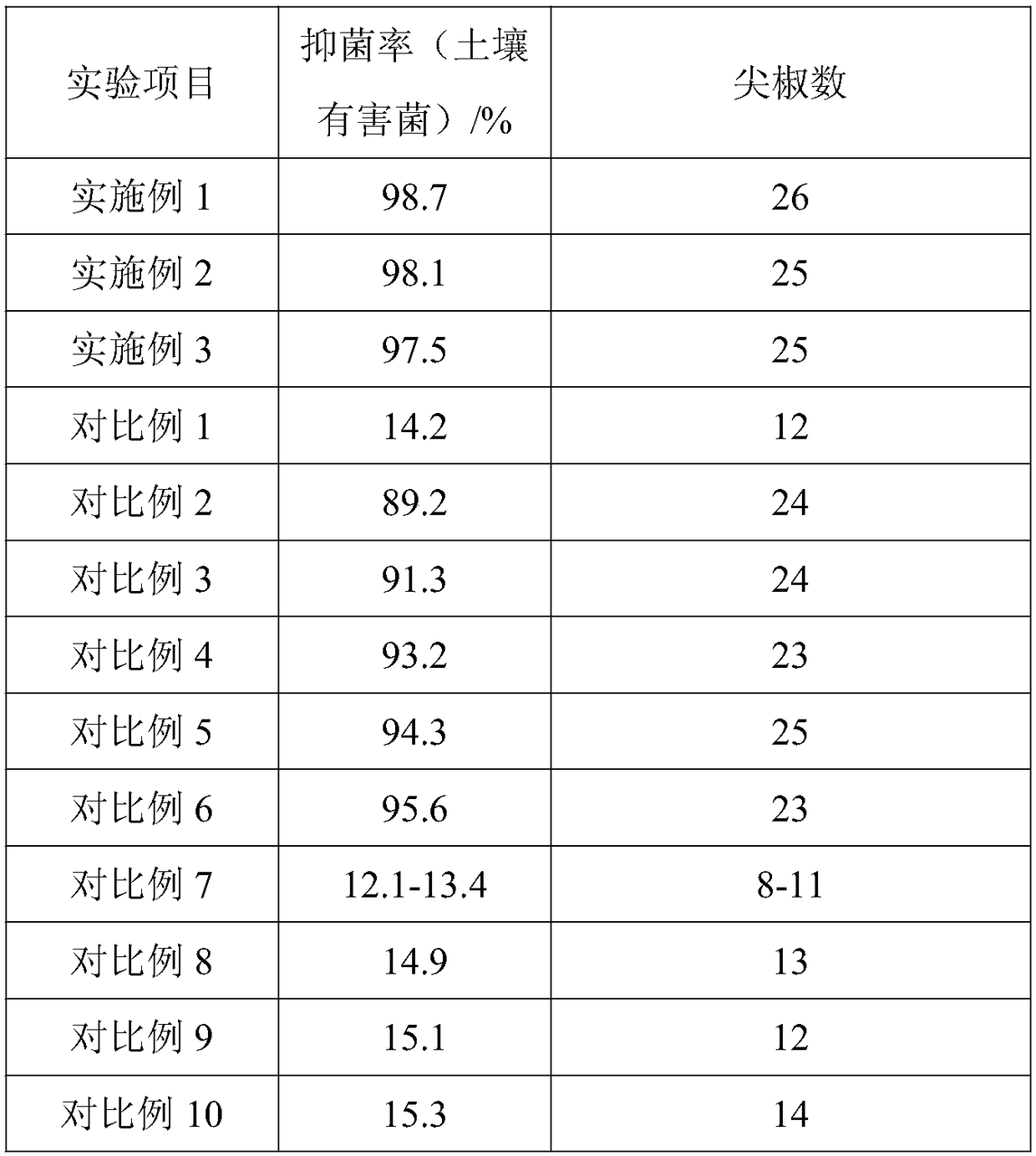

Examples

preparation example Construction

[0027] The preparation method of the antibacterial production-increasing composition containing copper humic acid comprises the following steps:

[0028] S1: Mix allantoin and oligosaccharin evenly, heat up to 40-50°C, keep warm for 10-20min, then stir at 450-650r / min for 15-25min, then add chlormequat, trinexapac-ethyl and methylpiperidine Mix well, stir at 850-1050r / min for 15-25min, then add copper humate, copper hydroxide and basic copper carbonate and mix evenly, stir at 1500-2500r / min for 20-40min, then cool to room temperature get the main material;

[0029] S2: Heat up the polylactic acid to 70-80°C, keep it warm for 20-30min, then add chitosan, antibacterial modification additives and slow-release fillers and mix evenly, continue to heat up to 90-110°C, keep it warm for 15-25min, and heat it at 850°C Stir at -1050r / min for 20-40min, then cool to 60-70°C, add silane coupling agent KH-550 and mix well, stir at 1200-1400r / min for 1-2h, cool to room temperature to obtain...

Embodiment 1

[0032] An antibacterial production-increasing composition containing copper humate, in parts by weight, comprising the following raw materials: 113 parts of allantoin, 25.6 parts of amino oligosaccharins, 18.9 parts of copper humate, 21.3 parts of chlormequat, 22.5 parts of ester, 23.6 parts of methylpiperium, 10.8 parts of copper hydroxide, 8.9 parts of basic copper carbonate, 8 parts of polylactic acid comparative example, 5.6 parts of chitosan, 2.4 parts of silane coupling agent KH-550, antibacterial modification additive 19.8 parts, slow release filler 26.4 parts.

[0033] The antibacterial modification additive is prepared according to the following process: 6 parts by weight of attapulgite clay and 13.5 parts of sodium chloride solution with a mass fraction of 8.6% are mixed uniformly, stirred for 2.4 hours, filtered and dehydrated, dried, and then Calcined at 435°C for 1.2h, then placed in 7.5 parts of lanthanum chloride solution with a mass fraction of 18.6%, stirred f...

Embodiment 2

[0040] An antibacterial production-increasing composition containing copper humate, in parts by weight, comprising the following raw materials: 80 parts of allantoin, 30 parts of amino oligosaccharins, 10 parts of copper humate, 30 parts of chlormequat, anti-lodging 10 parts of ester, 30 parts of methylpiperium, 8 parts of copper hydroxide, 15 parts of basic copper carbonate, 6 parts of polylactic acid, 8 parts of chitosan, 1 part of silane coupling agent KH-5501, 25 parts of antibacterial modification additive , 16 parts of slow-release fillers.

[0041] The antibacterial modified auxiliary agent is prepared according to the following process: 4 parts of attapulgite clay and 15 parts of sodium chloride solution with a mass fraction of 5% are mixed evenly by weight, stirred for 3 hours, filtered and dehydrated, dried, and then dried at 450 °C for 1.5h, then placed in 4 parts of lanthanum chloride solution with a mass fraction of 35%, stirred for 1h, filtered and dehydrated, dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com