A kind of method that prepares nano copper hydroxide by acid copper chloride etching waste liquid

A technology for etching waste liquid and copper hydroxide, applied in the direction of copper oxide/copper hydroxide, nanotechnology, alkali metal chloride, etc., can solve the problem of unspecified filtrate and lotion treatment method washing water consumption, unspecified copper recovery efficiency, product washing difficulties, etc., to achieve the effect of reducing raw material consumption, high recovery rate, and easy washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

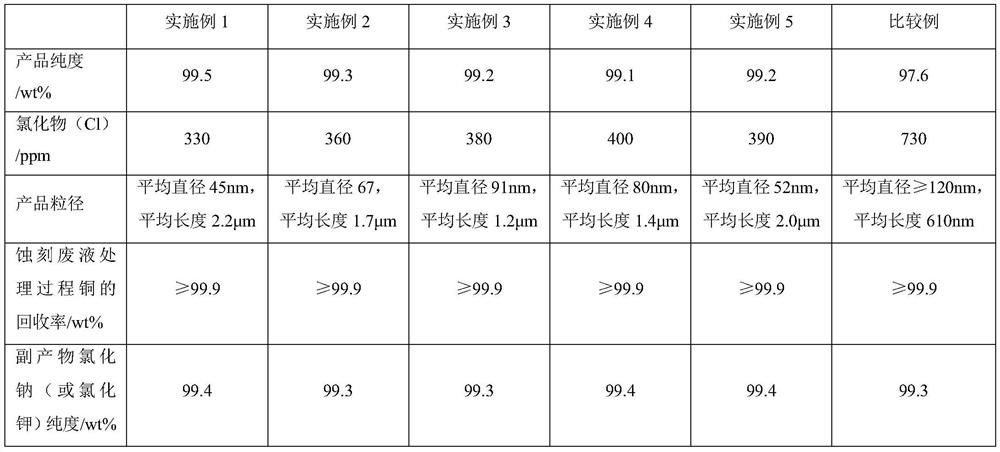

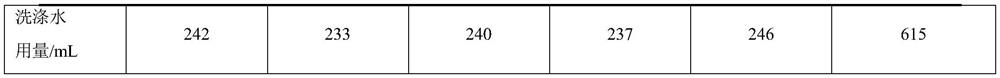

Examples

Embodiment 1

[0023] Add a certain amount of additives and water to 100mL of acidic copper chloride etching waste liquid, mix evenly to obtain a mixed liquid; add the precipitant slowly and uniformly within 40 minutes, adjust the pH of the solution to 13.0, and stir the reaction at 30°C After aging for 90 minutes, filter, wash the filter cake with water until there is no chloride ion; dry the filter cake at 25°C to constant weight to obtain the product nano-copper hydroxide.

[0024] Among them, Cu in the mixture 2+ The concentration of hydrochloric acid is 50.0g / L, and the concentration of hydrochloric acid is 1.60mol / L; the auxiliary agent is a mixture of polyvinylpyrrolidone (K-15) and sodium tridecyl sulfate, and sodium tridecyl sulfate and polyvinyl pyrrolidone ( The mass ratio of K-15) is 0.20:1; the mass ratio of auxiliary agent to copper is 0.0008:1. Precipitating agent is sodium hydroxide, its concentration is 10mol / L.

Embodiment 2

[0026] Add a certain amount of additives and water to 100mL of acidic copper chloride etching waste solution, mix well to obtain a mixed solution; slowly and uniformly add a precipitant within 50 minutes, adjust the pH of the solution to 12.9, and stir the reaction at 20°C After aging for 70 minutes, filter for another 70 minutes, wash the filter cake with water until there is no chloride ion; dry the filter cake at 50°C to constant weight to obtain the product nano-copper hydroxide.

[0027] Among them, Cu in the mixture 2+ The concentration of hydrochloric acid is 70.0g / L, and the concentration of hydrochloric acid is 2.24mol / L; the auxiliary agent is a mixture of polyvinylpyrrolidone (K-25) and sodium undecyl sulfate, and sodium undecyl sulfate and polyvinylpyrrolidone ( The mass ratio of K-25) is 0.16:1; the mass ratio of auxiliary agent to copper is 0.001:1. Precipitating agent is potassium hydroxide, its concentration is 4mol / L.

Embodiment 3

[0029] Add a certain amount of additives and water to 100mL of acidic copper chloride etching waste solution, mix well to obtain a mixed solution; slowly and uniformly add a precipitant within 60 minutes, adjust the pH of the solution to 12.8, and stir the reaction at 10°C After aging for 100 minutes, filter for another 50 minutes, wash the filter cake with water until there is no chloride ion; dry the filter cake at 65°C to constant weight to obtain the product nano-copper hydroxide.

[0030] Among them, Cu in the mixture 2+ The concentration of hydrochloric acid is 100g / L, and the concentration of hydrochloric acid is 3.20mol / L; the additive is a mixture of polyvinylpyrrolidone (K-30) and sodium lauryl sulfate, and the mixture of sodium lauryl sulfate and polyvinylpyrrolidone (K-30 ) is 0.05:1 in mass ratio; the mass ratio of auxiliary agent to copper is 0.005:1. The precipitating agent is a mixture of sodium hydroxide and sodium carbonate, the molar ratio of sodium carbona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com