Hydrogenation dethiolizing catalyst, preparation method thereof and application thereof

A hydrodesulfurization and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve unqualified mercaptan sulfur and high octane loss and other problems, to achieve the effects of high liquid yield, less octane loss, and low olefin hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Preparation of Vector T-1

[0034] Use 1000 grams of aluminum hydroxide powder, add 20 milliliters of nitric acid, 700 milliliters of deionized water and extrusion aid, mix and roll, extrude into a clover shape, dry at 110 ° C for 3 hours, and roast at 550 ° C for 3 hours to obtain the carrier T-1 .

[0035] Preparation of Vector T-2

[0036] Use 900g of aluminum hydroxide powder, add 18ml of nitric acid, 600ml of deionized water, 450g of silica sol and extrusion aid, mix and roll, extrude into a clover shape, dry at 110°C for 3 hours, and roast at 550°C for 3 hours to obtain the carrier T-2.

Embodiment 1

[0038] Mix 30 grams of copper nitrate, 18 grams of zinc nitrate, 7 grams of ammonium dihydrogen phosphate and 60 milliliters of deionized water, dissolve at 60 ° C for 1 hour to obtain 65 milliliters of Cu-Zn-P co-immersion solution, and 100 grams of roasted carrier T-1 was impregnated with the above impregnation solution at room temperature, dried at 120°C for 8 hours, and calcined at 500°C for 8 hours to obtain catalyst RM-1.

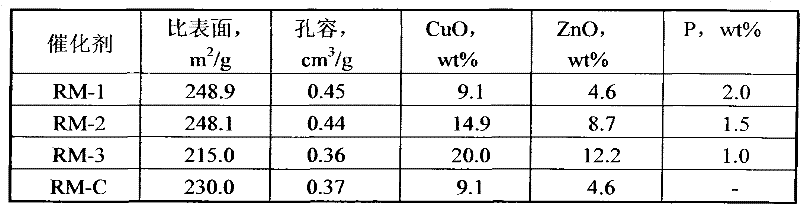

[0039] The physical properties of the RM-1 catalyst are listed in Table 1.

Embodiment 2

[0044] Mix 45 grams of copper nitrate, 32 grams of zinc nitrate, 4.7 grams of phosphoric acid and 60 milliliters of deionized water, dissolve at 60 ° C for 1 hour to obtain 65 milliliters of Cu-Zn-P co-immersion solution, and 100 grams of roasted carrier T-1 The catalyst RM-2 was obtained by impregnating with the above impregnating solution at room temperature, drying at 120°C for 8 hours, and calcining at 500°C for 8 hours.

[0045] The physical properties of the RM-2 catalyst are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com