Catalyst for synthesizing low carbon mellow with synthesis gas and preparation method thereof

A catalyst and low-carbon alcohol technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of low alcohol selectivity, uneconomical, low CO conversion rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

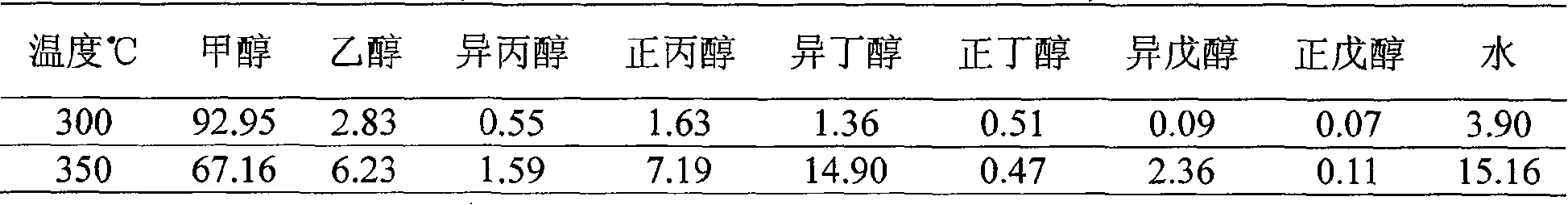

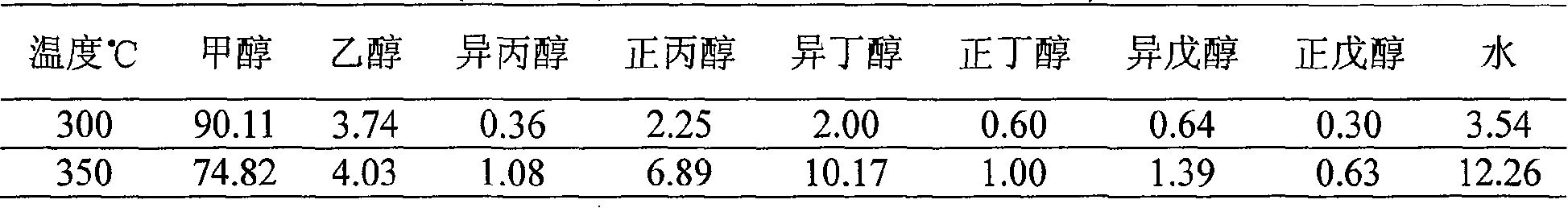

Examples

Embodiment 1

[0016] According to the general formula Cu(Zn) 1.25 (Cr) 0.38 (Al) 0.38 (M) 0 (A)e(O)x. Take 178ml of 2.0M copper nitrate solution, 222ml of 2.0M zinc nitrate solution, 100ml of 1.35M aluminum nitrate solution, and 100ml of 1.35M chromium nitrate solution to prepare a 1000ml mixed solution, and mix the mixed solution with sodium carbonate in a sedimentation tank with stirring Co-precipitate the solution, control the precipitation temperature at 75°C to 80°C, and the pH value of the end point of the precipitation is 7.5, then age at 80°C to 85°C for 30 minutes, then wash, dry, crush, and roast at 320°C to obtain 11.5g K 2 CO 3 Prepare a 100ml aqueous solution, mix it with the above-mentioned base material evenly, then dry it, roast it at 350°C, add an appropriate amount of water and graphite, and finally press it into a cylindrical tablet, and then crush it into 0.45mm-0.90mm particles to obtain a usable catalyst (K1)

Embodiment 2

[0018] According to the general formula Cu(Zn) 0.75 (Cr) 0.3 (Al) 0.3 (M) 0 (A)e(O)x. Take 229ml of 2.0M copper nitrate solution, 171ml of 2.0M zinc nitrate solution, 100ml of 1.35M aluminum nitrate solution, and 100ml of 1.35M chromium nitrate solution to prepare a 1000ml mixed solution, and mix the mixed solution with sodium carbonate in a sedimentation tank with stirring Co-precipitate the solution, control the precipitation temperature at 75°C to 80°C, and the pH value of the end point of the precipitation is 7.5, then age at 80°C to 85°C for 30 minutes, and then wash, dry, pulverize, and roast at 320°C to obtain the base material. Take 6.13gK 2 CO 3 Prepare a 100ml aqueous solution, mix it with the above-mentioned base material evenly, then dry it, roast it at 350°C, add an appropriate amount of water and graphite, and finally press it into a cylindrical tablet, and then crush it into 0.45mm-0.90mm particles to obtain a usable catalyst (K2).

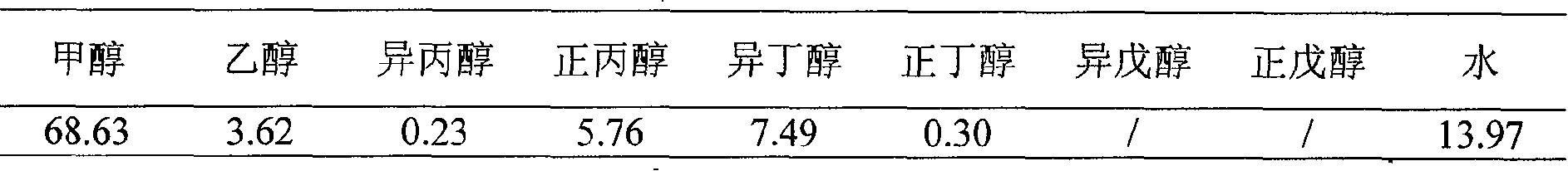

Embodiment 3

[0020] According to the general formula Cu(Zn) 1.5 (Cr) 0.65 (Al) 0.65 (M) 0.12 (A)e(O)x. Take 178ml of 2.0M copper nitrate solution, 266ml of 2.0M zinc nitrate solution, Al(NO3)3 9H2O86.5g, Ce(NO 3 ) 3 ·6H 2 O11.6g, Cr(NO 3 ) 3 9H 2 O92.3g, 50% Mn(NO 3 ) 3 9.1g of the solution is prepared into 1000ml mixed solution, and the mixed solution and sodium carbonate solution are co-precipitated in a precipitation tank with stirring, the precipitation temperature is controlled at 75°C to 80°C, and the pH value at the end of the precipitation is 7.5, and then at 80°C to Aged at 85°C for 30 minutes, then washed, dried, crushed, and roasted at 320°C to obtain the base material. Take 4.3gK 2 CO 3 Prepare a 100ml aqueous solution, mix it with the above-mentioned base material evenly, then dry it, roast it at 350°C, add an appropriate amount of water and graphite, and finally press it into a cylindrical tablet, and then crush it into 0.45mm-0.90mm particles to obtain a usable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com