Mesoporous carbon material loaded cobalt-based catalyst and preparation method thereof

A cobalt-based catalyst and mesoporous carbon technology, which is applied in catalyst activation/preparation, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc., can solve the problem that it is difficult to obtain active phases with high dispersion and high reduction degree on the catalyst surface, and difficult to reduce Species and other issues, to achieve the effect of low CO2 generation rate, uniform dispersion and high CO conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] A preparation method of a cobalt-based catalyst supported by mesoporous carbon material GMC, comprising the following steps:

[0080] (1) Preparation of ordered mesoporous carbon materials (GMC):

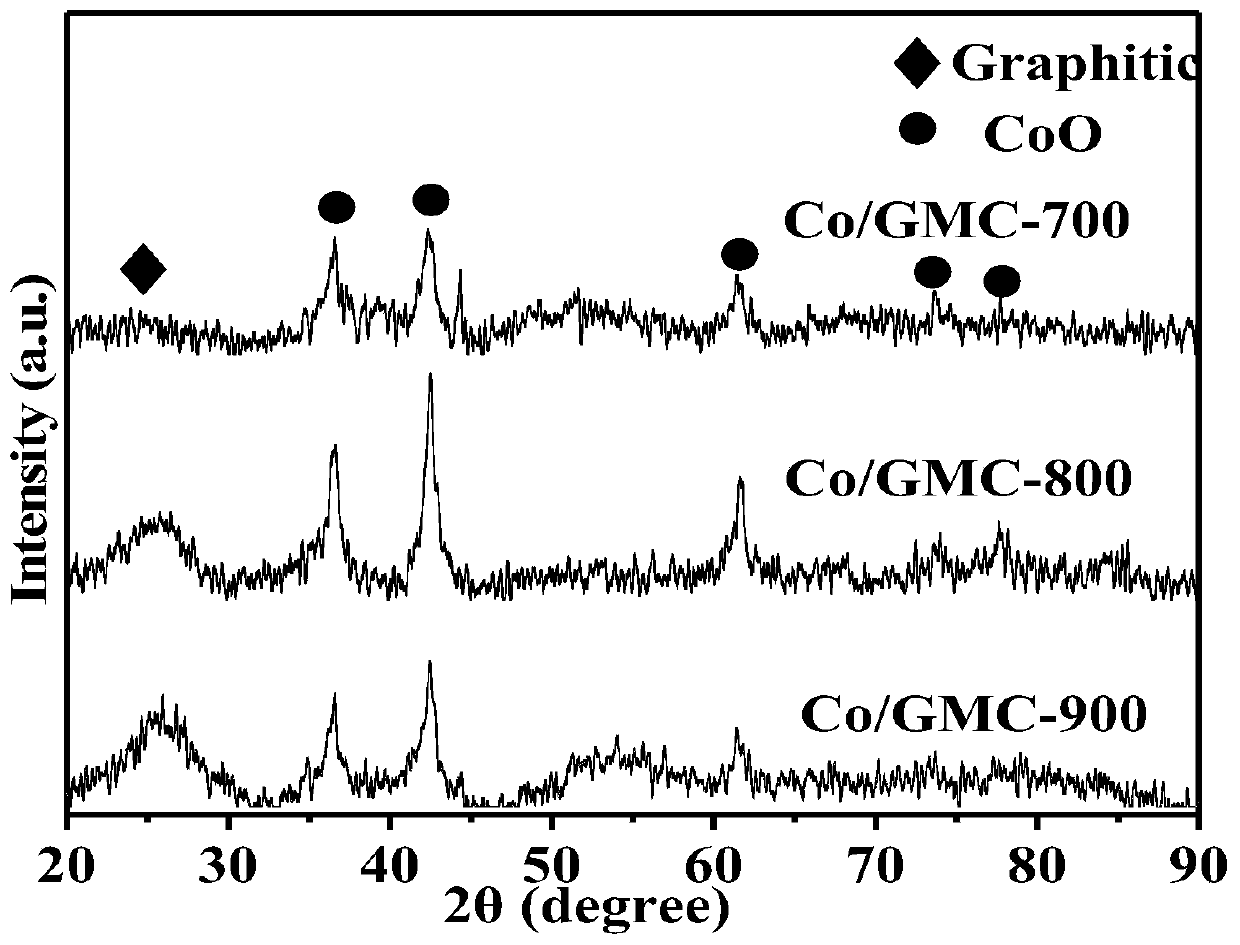

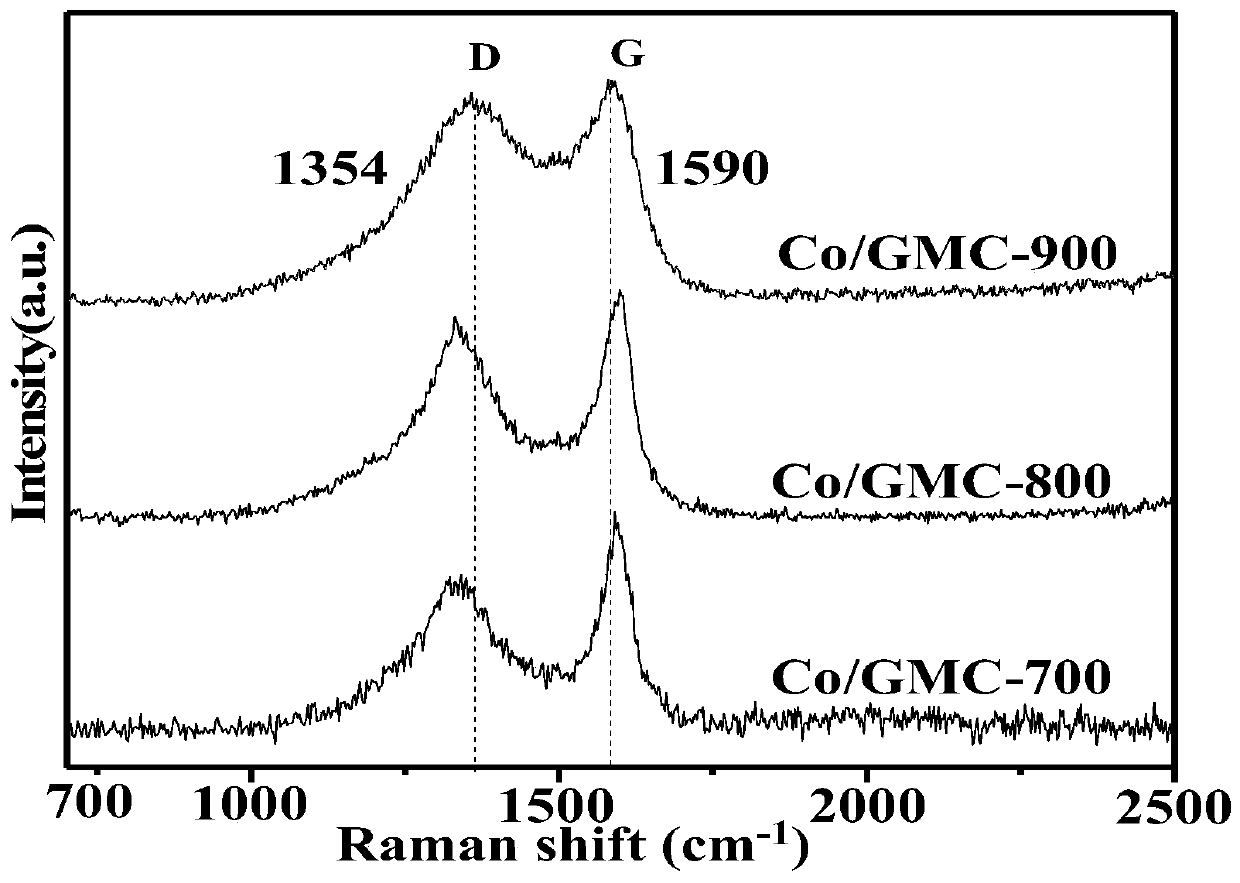

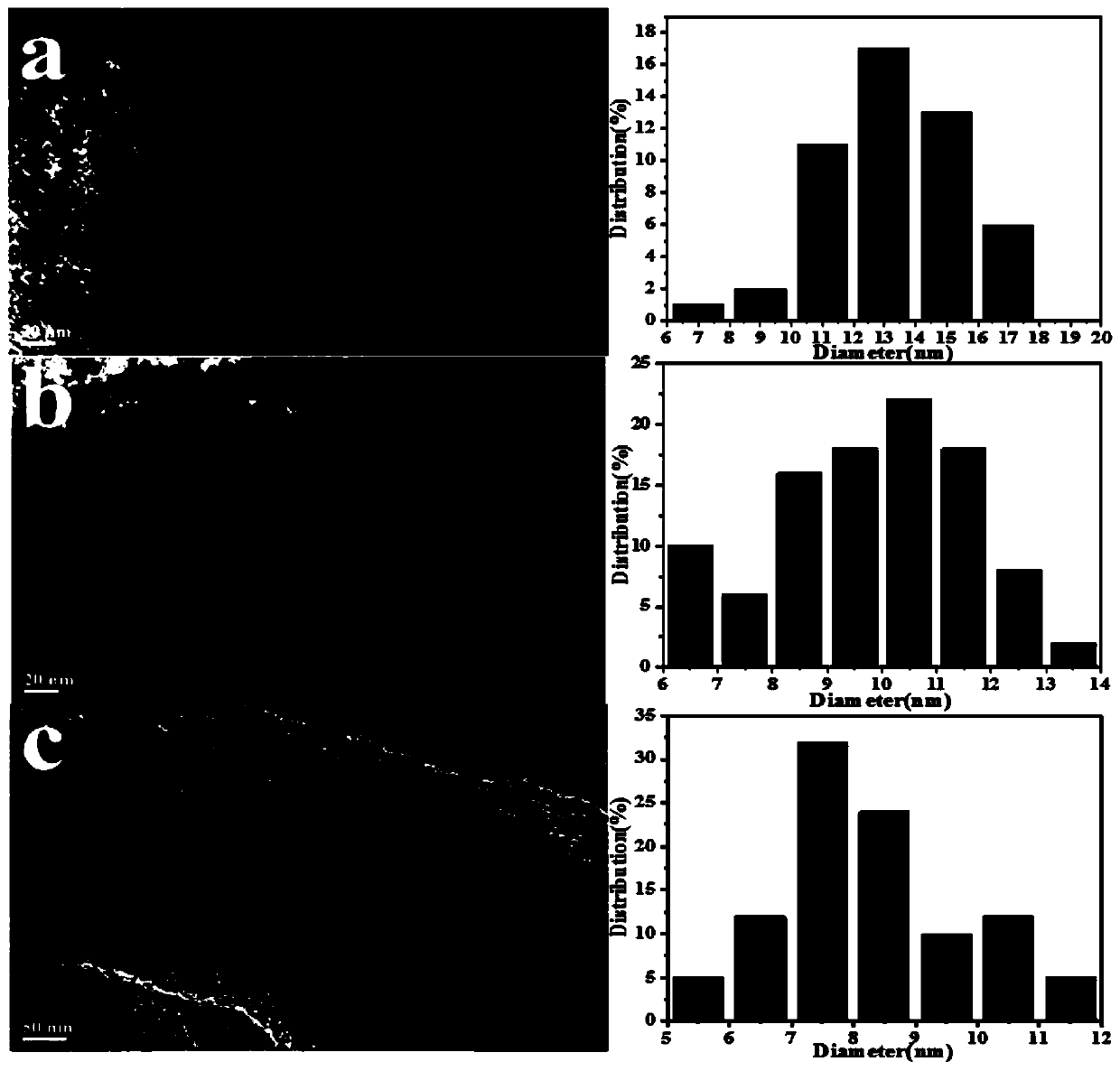

[0081] The mixture of SBA-15 and soybean oil (mass ratio 1:2) was mixed with a ball mill at 400rpm·min using the solid-liquid ball milling template method. -1 After ball milling for 5 hours at a rotating speed, mix evenly, then divide the mixture into three parts, and transfer them to a quartz tube furnace successively. 2 Under protection at 4°C·min -1 The temperature was raised to 700, 800 and 900°C for carbonization for 5 hours respectively, and three materials calcined at different temperatures were produced. Use NaOH solution (concentration 2mol / L) to etch three times, each etching time is 24h, so as to remove the hard template agent SBA-15, and finally obtain porous materials calcined at different temperatures, respectively marked as GMC-700, GMC -800, GMC-900.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com