Method for preparing hydrogenation catalyst by loading copper oxide on silica gel carrier

A hydrogenation catalyst, copper oxide technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry and other directions, can solve the problems of high 2-methylfuran selectivity, incomplete catalyst reduction, environmental pollution and the like, Achieve high catalytic reduction activity, promote environmental protection, and overcome the effects of low loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

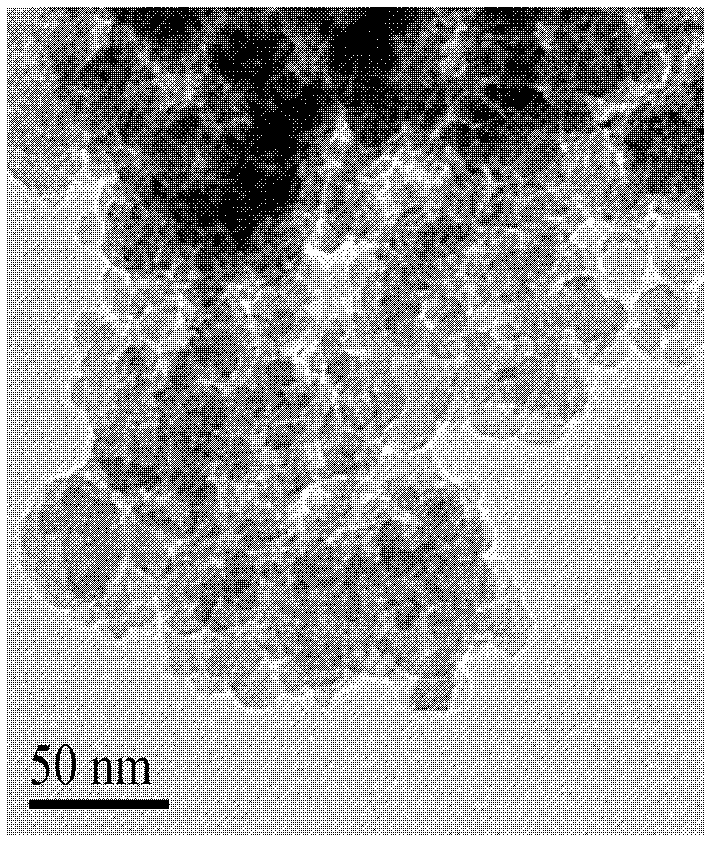

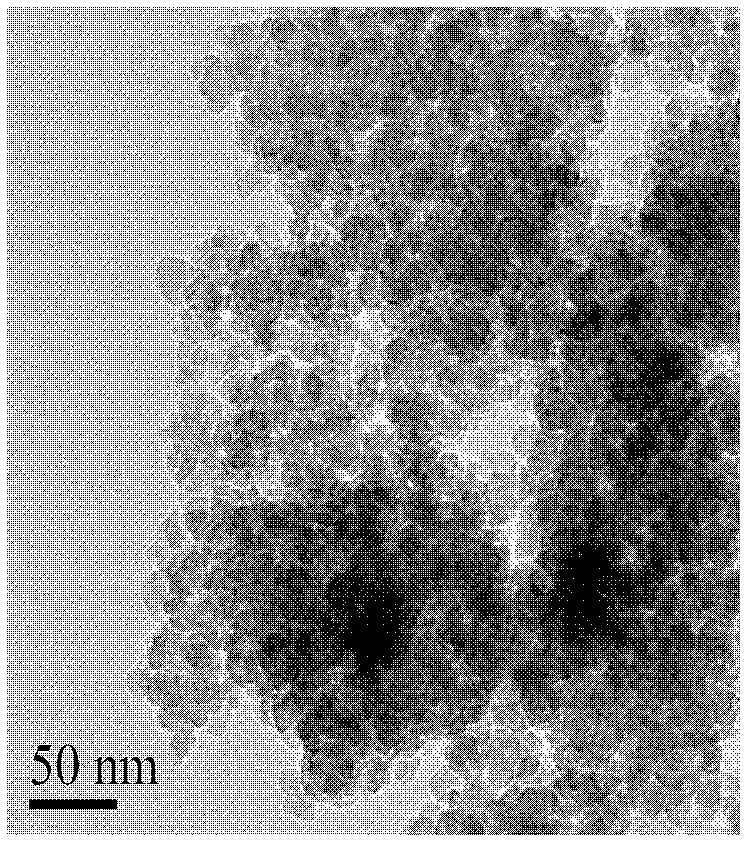

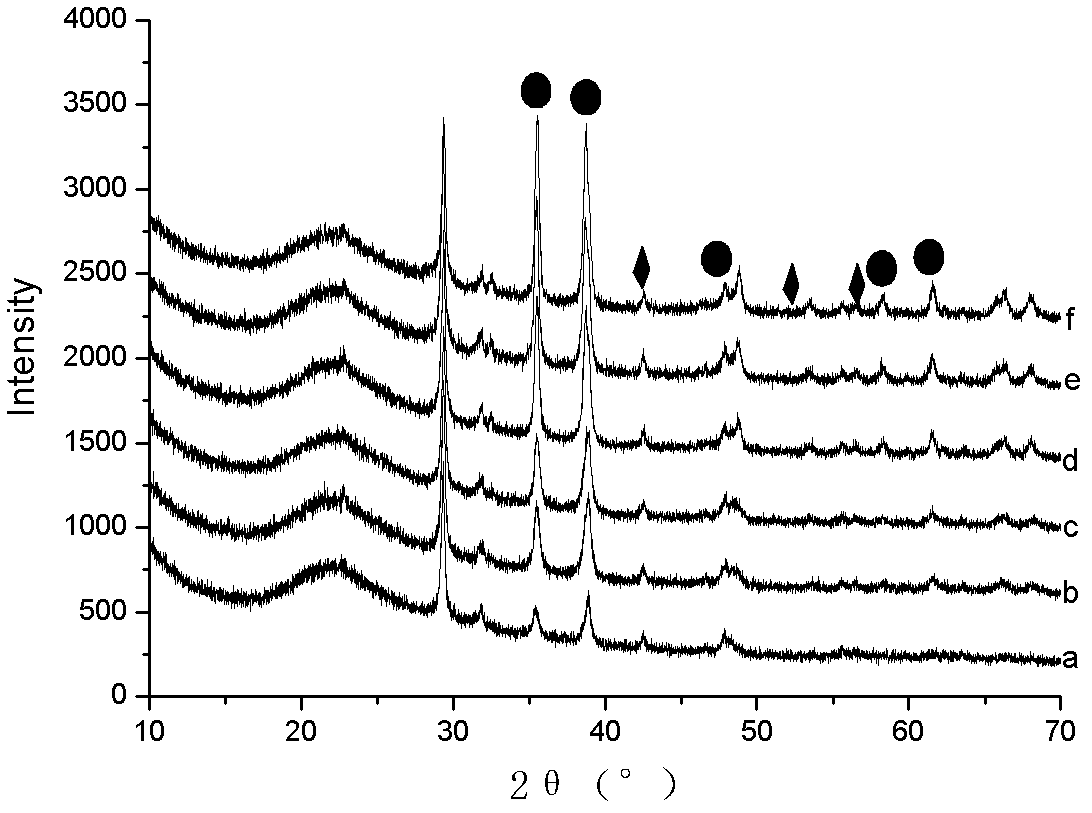

[0032] Copper Oxide Hydrogenation Catalyst Cu Supported on Silica Carrier 15 Ce 2 / SiO 2 The preparation method, it comprises the steps:

[0033] 1) Take analytically pure Cu(NO 3 ) 2 ·3H 2 O 2.84g, Ce(NO 3 ) 3 ·6H 2 O 0.30g was dissolved in 5ml deionized water, and added to a constant pressure burette for later use. Then take 20ml industrial alkaline silica sol (density 1.1g / cm 3 , 30wt SiO 2 %) with 2mol / L nitric acid solution to adjust pH=2, and mechanically stir and mix. Then, drop the mixed solution of copper nitrate and cerium nitrate in the constant pressure buret into the above-mentioned silica sol solution at a rate of 2 drops / s, and stir while adding. After the mixed solution of copper nitrate and cerium nitrate is dripped, continue to stir for 30 minutes to form a uniform sol;

[0034] 2) Take 2mL of 4.5mol / L anhydrous sodium carbonate solution, add another constant pressure burette, and add it to the above sol at a rate of 2 drops / s, stir while adding, ...

Embodiment 2

[0038] Copper Oxide Hydrogenation Catalyst Cu Supported on Silica Carrier 15 Ce 3 / SiO 2 The preparation method, it comprises the steps:

[0039] 1) Take analytically pure Cu(NO 3 ) 2 ·3H 2 O 2.84g, Ce(NO 3 ) 3 ·6H 2 O 0.45g was dissolved in 5ml of deionized water, and added to a constant pressure burette for later use. Then take 20ml of industrial silica sol and adjust the pH to 2 with 2mol / L nitric acid solution, and mechanically stir and mix. Then, the mixed solution of copper nitrate and cerium nitrate in the constant pressure burette was dropped into the stirred silica gel solution at a rate of 2 drops / s. After the mixed solution of copper nitrate and cerium nitrate is dripped, continue to stir for 30 minutes to form a uniform sol;

[0040] 2) Take 3.5mL 4.5mol / L anhydrous sodium carbonate solution, add another constant pressure burette, and add it to the above sol at a rate of 2 drops / s, stir while adding, stop dropping after it is completely gelled and stirri...

Embodiment 3

[0044] Copper Oxide Hydrogenation Catalyst Cu Supported on Silica Carrier 15 Ce 4 / SiO 2 The preparation method, it comprises the steps:

[0045] 1) Take analytically pure Cu(NO 3 ) 2 ·3H 2 O 2.84g, Ce(NO 3 ) 3 ·6H 2 O 0.60g was dissolved in 5ml of deionized water, and added to a constant pressure burette for later use. Then take 20ml of industrial silica sol and adjust the pH to 2 with 2mol / L nitric acid solution, and mechanically stir and mix. Then, the mixed solution of copper nitrate and cerium nitrate in the constant pressure burette was dropped into the stirred silica gel solution at a speed of 2 s / drop. After the mixed solution of copper nitrate and cerium nitrate is dripped, continue to stir for 30 minutes to form a uniform sol;

[0046] 2) Take 3.5mL 4.5mol / L anhydrous sodium carbonate solution, add another constant pressure burette, and add it into the above sol at a rate of 2 drops / s, stir while adding, stop stirring after it is completely gelled, Aged at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com