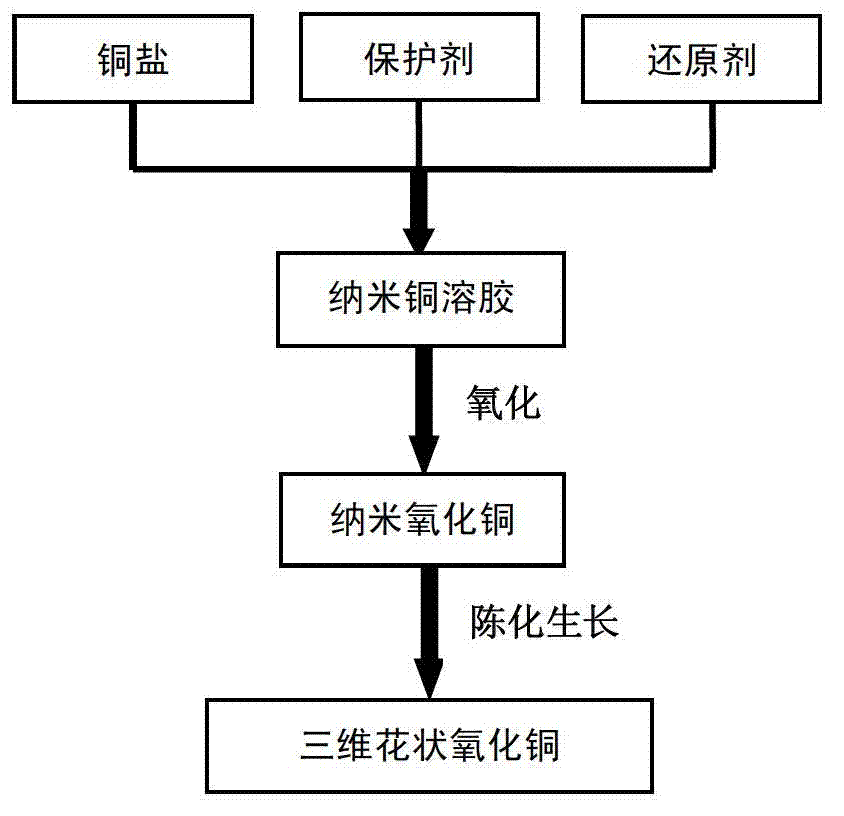

Simple preparation method of three-dimensional flower-shaped micro-nano copper oxide

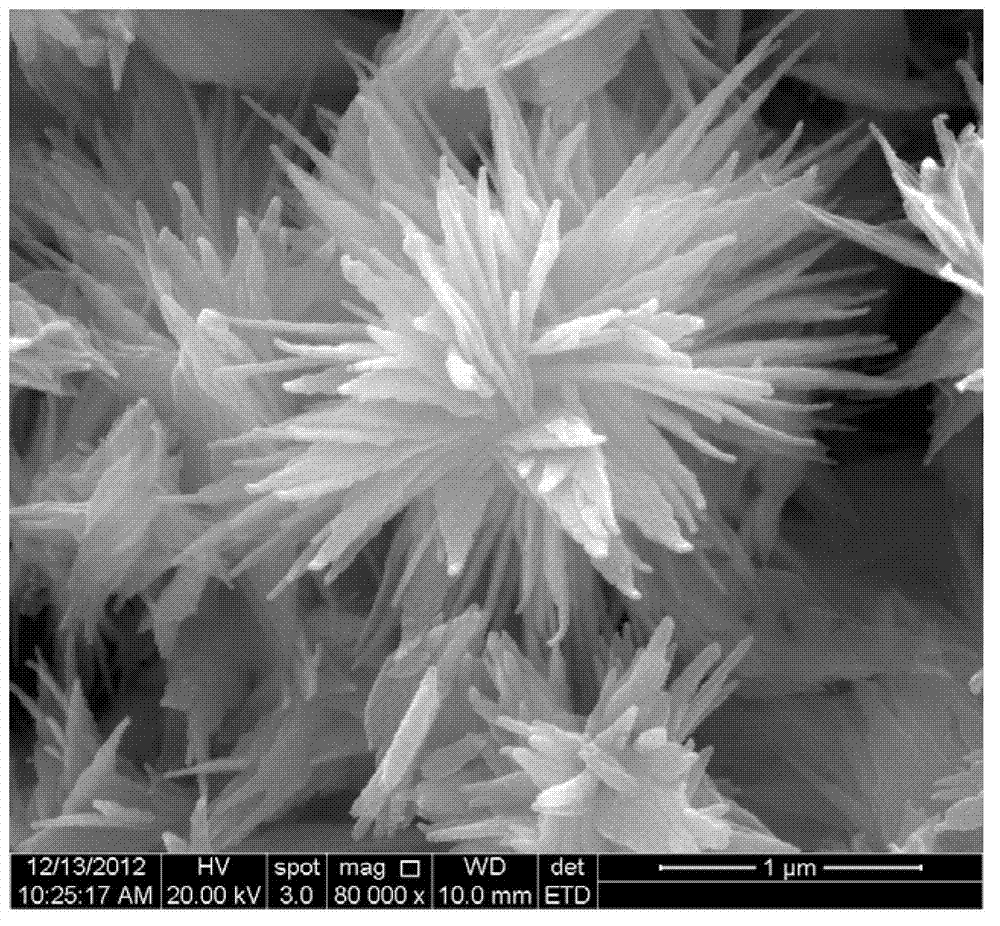

A three-dimensional flower-shaped copper oxide technology, applied in the field of copper oxide, can solve the problems of high cost, complicated flower-shaped micro-nano copper oxide, high temperature and high pressure, etc., and achieve the effects of reduced production costs, large surface roughness, and excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] (3) Preparation of nano-copper sol:

[0038] The mixture of reducing agent and protective agent is stirred at a speed of 600-1200r / min, and the water bath is kept at a constant temperature of 30-40°C. The copper salt solution is slowly added dropwise into the above-mentioned mixture by using a peristaltic pump, and the mixture is heated at 600-1200r / min. The reaction time is 60-90 minutes under the rotating speed to obtain nano-copper sol.

[0039] (4) Oxidation of nano copper:

[0040] The prepared nano-copper sol is placed in an environment of 0-10° C. for 2-7 days, so that the protective agent is partially analyzed at a low temperature, so that the nano-copper loses its protection and is oxidized into copper oxide particles.

[0041] (5) Growth of copper oxide particles:

[0042] The nano-copper oxide particles obtained by oxidation can aggregate and grow into three-dimensional flower-shaped copper oxide due to their high surface energy and loss of the protection o...

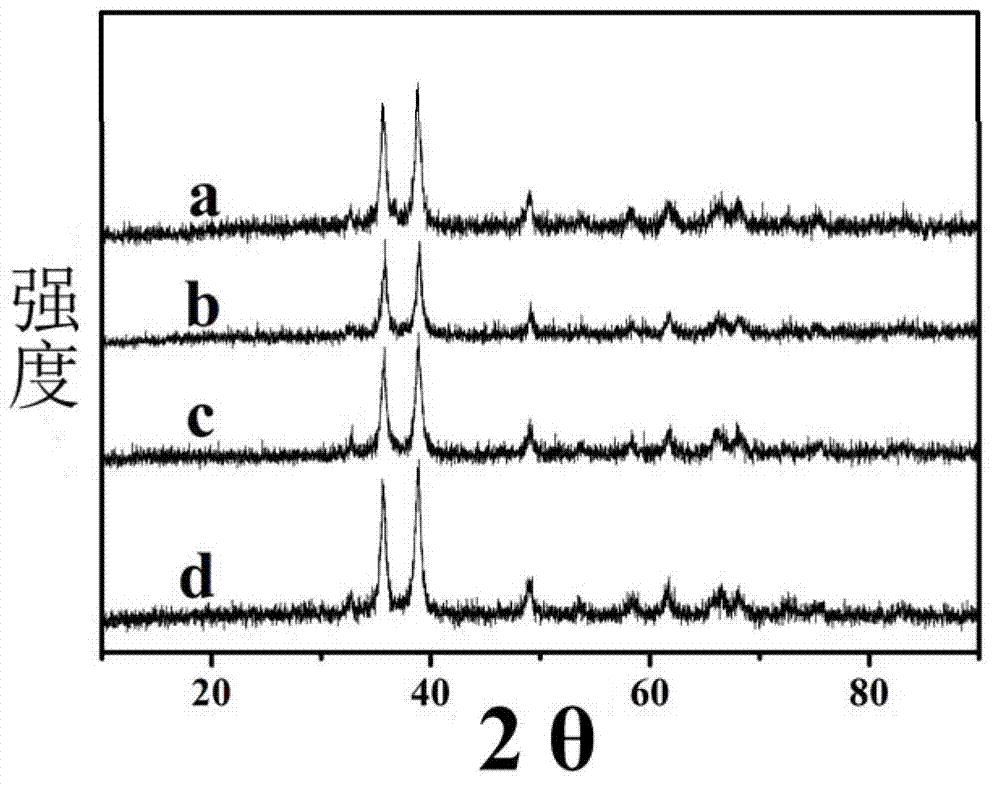

Embodiment 1

[0047] Weigh 0.4542g of reducing agent potassium borohydride and 1.4578g of protecting agent cetyltrimethylammonium bromide, dissolve them in 200ml ultrapure water at room temperature, and prepare a reducing agent solution with a molar concentration of 0.04mol / L And 0.02mol / L protective agent solution. The ratio of reducing agent to protecting agent is 1:0.5. Accurately weigh 0.4994g of copper sulfate pentahydrate, dissolve it in 30ml of ultrapure water at room temperature, and prepare a divalent copper ion solution with a molar concentration of 0.05mol / L. The molar ratio of divalent copper particles to potassium borohydride is 1:4. In a water bath at 30°C, the mixture of potassium borohydride and cetyltrimethylammonium bromide was stirred at a speed of 1200r / min, and the divalent copper particle solution was mixed with a peristaltic pump at a rate of one drop per second. Slowly add it dropwise into the above mixed solution, and react for 60 minutes at a rotating speed of 12...

Embodiment 2

[0049]Weigh 0.4542g of reducing agent potassium borohydride and 2.1867g of protective agent cetyltrimethylammonium bromide, dissolve in 200ml ultrapure water at room temperature, and prepare a reducing agent solution with a molar concentration of 0.04mol / L And 0.03mol / L protective agent solution. The ratio of reducing agent to protecting agent is 1:0.75. Accurately weigh 0.4994g of copper sulfate pentahydrate, dissolve it in 30ml of ultrapure water at room temperature, and prepare a divalent copper ion solution with a molar concentration of 0.05mol / L. The molar ratio of divalent copper particles to potassium borohydride is 1:4. In a water bath at 30°C, the mixture of potassium borohydride and cetyltrimethylammonium bromide was stirred at a speed of 1200r / min, and the divalent copper particle solution was mixed with a peristaltic pump at a rate of one drop per second. Slowly add it dropwise into the above mixed solution, and react for 60 minutes at a rotating speed of 1200r / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com