Preparation method of porous cobaltosic oxide nanobelt

A technology of cobalt tetroxide nanometer and cobalt salt, which is applied in the directions of cobalt oxide/cobalt hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of high synthesis cost, difficulty in large-scale production, etc., and achieves low price, easy large-scale synthesis, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) First dissolve cobalt nitrate and dicyandiamide in water to form a mixed solution, the concentration of cobalt nitrate is 50mmol / l, and the molar ratio of cobalt nitrate and dicyandiamide is 1:4;

[0026] (2) Then put the mixed solution into a hydrothermal kettle, and conduct a hydrothermal reaction at 180°C, and the reaction time is 12h;

[0027] (3) After the hydrothermal reaction, the reaction product was separated and washed, and then the reaction product was calcined at 500°C for 2 hours to obtain porous cobalt trioxide nanobelts.

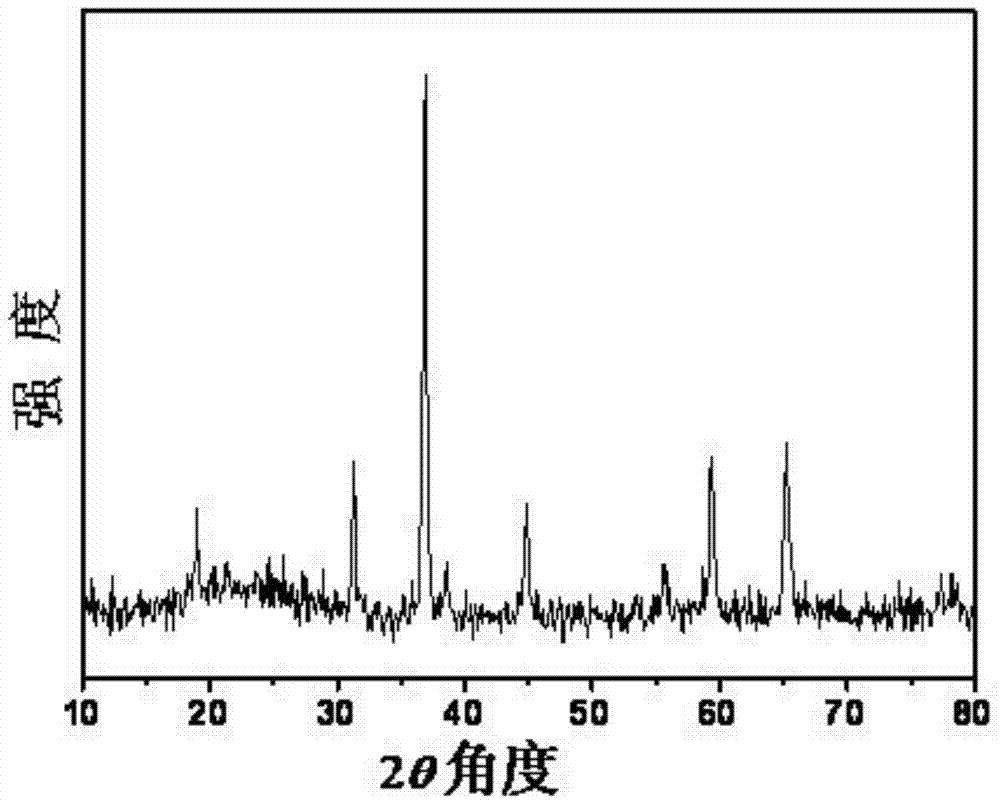

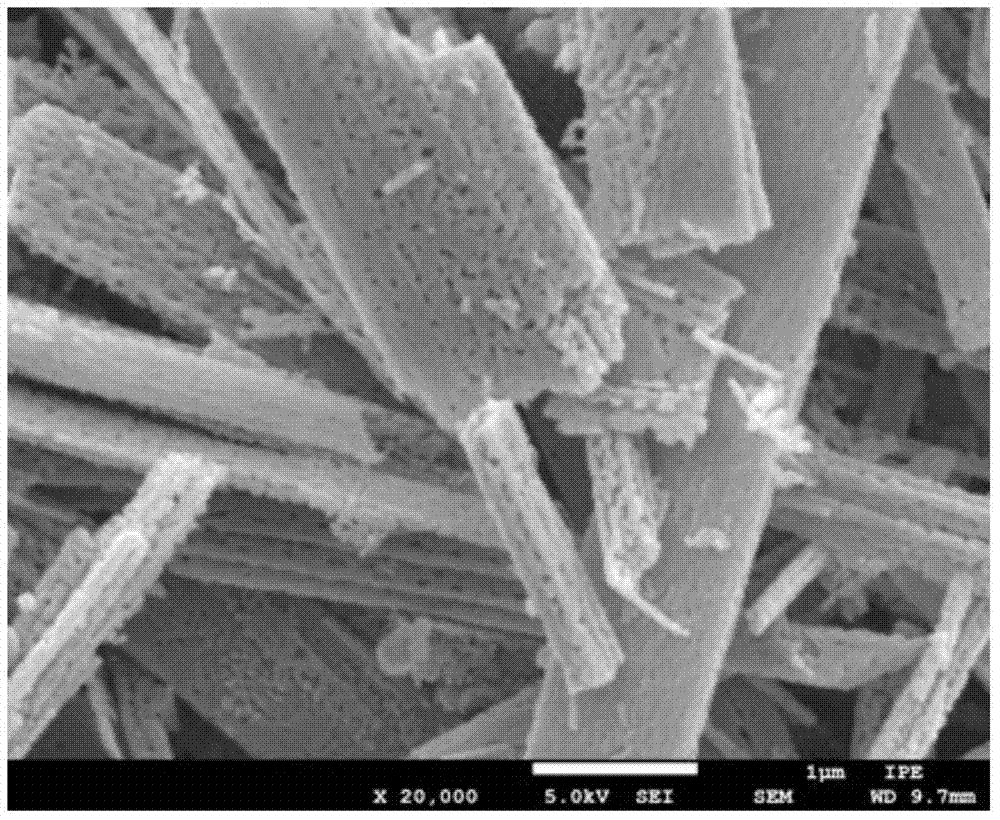

[0028] The black powder product prepared above was subjected to XRD test on the X'PertPROMPD multifunctional X-ray diffractometer produced by Panalytical Company (Panalytical) in the Netherlands. figure 1 It is the XRD spectrum of the black powder product obtained in Example 1. The diffraction peak in the spectrum is a typical spinel structure cobalt tetroxide characteristic diffraction peak. According to the standard powder diffrac...

Embodiment 2

[0033] (1) First dissolve cobalt nitrate and dicyandiamide in water to form a mixed solution, the concentration of cobalt nitrate is 10mmol / l, and the molar ratio of cobalt nitrate and dicyandiamide is 1:1;

[0034] (2) Then put the mixed solution into a hydrothermal kettle, and conduct a hydrothermal reaction at 130°C, and the reaction time is 20h;

[0035] (3) After the hydrothermal reaction is finished, the reaction product is separated and washed, and then the reaction product is calcined at 400° C. for 10 h to obtain porous cobalt trioxide nanobelts.

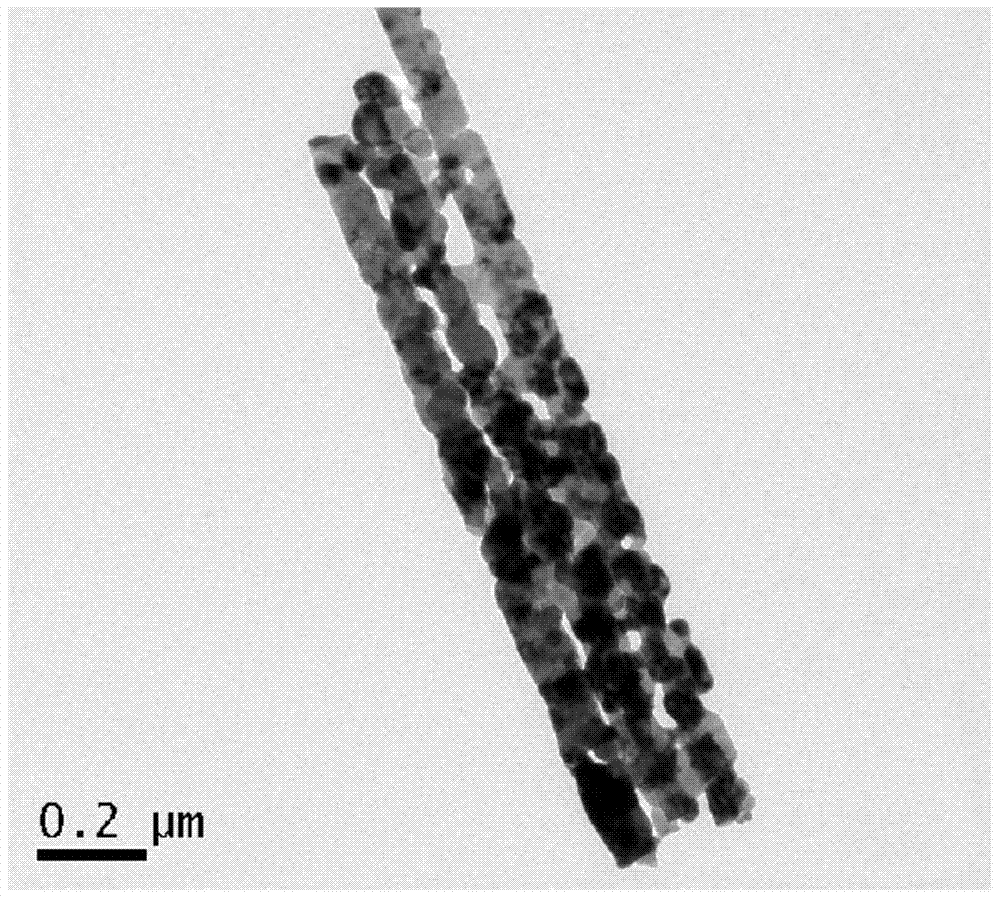

[0036] XRD spectrum analysis product is cubic cobalt tetroxide. SEM photos show that the morphology of cobalt tetroxide presents a porous band structure with a width of 150nm-200nm. The TEM photos show that the cobalt trioxide nanoribbon has a size of about 200nm, is formed by the assembly of nanoparticles with a size of 30nm-50nm, and has a pore diameter of about 25nm. The specific surface area measured by nitrogen adsor...

Embodiment 3

[0038] (1) First dissolve cobalt nitrate and dicyandiamide in water to form a mixed solution, the concentration of cobalt nitrate is 150mmol / l, and the molar ratio of cobalt nitrate and dicyandiamide is 1:7;

[0039] (2) Then put the mixed solution into a hydrothermal kettle, and conduct a hydrothermal reaction at 200°C, and the reaction time is 8h;

[0040] (3) After the hydrothermal reaction, the reaction product was separated and washed, and then the reaction product was calcined at 700°C for 1 hour to obtain porous cobalt trioxide nanobelts.

[0041] XRD spectrum analysis product is cubic cobalt tetroxide. SEM photos show that the morphology of cobalt tetroxide presents a porous band structure with a width of 100nm-500nm. The TEM photos show that the cobalt trioxide nanoribbon has a size of about 250nm, is formed by assembling nanoparticles with a size of 40nm-60nm, and has a pore diameter of about 25nm. The specific surface area measured by nitrogen adsorption instrumen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com