Environment-friendly high-temperature self-gel-breaking resistance reducing agent as well as preparation method and application thereof

A drag-reducing agent and an environment-friendly technology, which is applied in the field of environment-friendly high-temperature self-breaking drag-reducing agent and its preparation, can solve the problems of inaccurate addition, fluctuation of gel-breaking effect, unautomated addition of gel-breaker, etc., and achieve saving cost, reduce preparation cost, and reduce the effect of process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The second aspect of the present invention provides a method for preparing an environment-friendly high-temperature self-breaking drag-reducing agent, wherein the method includes:

[0031] (1) uniformly mixing the polymerized monomer, stabilizer, oxidizing agent, precipitation agent and water to obtain a clear solution;

[0032] (2) In an inert atmosphere, the reducing agent is mixed with the clear solution to perform a polymerization reaction to obtain the environment-friendly high-temperature self-breaking drag reducing agent.

[0033] In the present invention, a two-phase aqueous reaction polymerization system is used to prepare the drag reducing agent, and its continuous phase is an aqueous phase. During the preparation process, by adjusting the feeding sequence of the oxidizing agent and the reducing agent, the gel breaker is added in advance during the preparation of the drag reducing agent, and together with the copolymer in the drag reducing agent, a uniform liq...

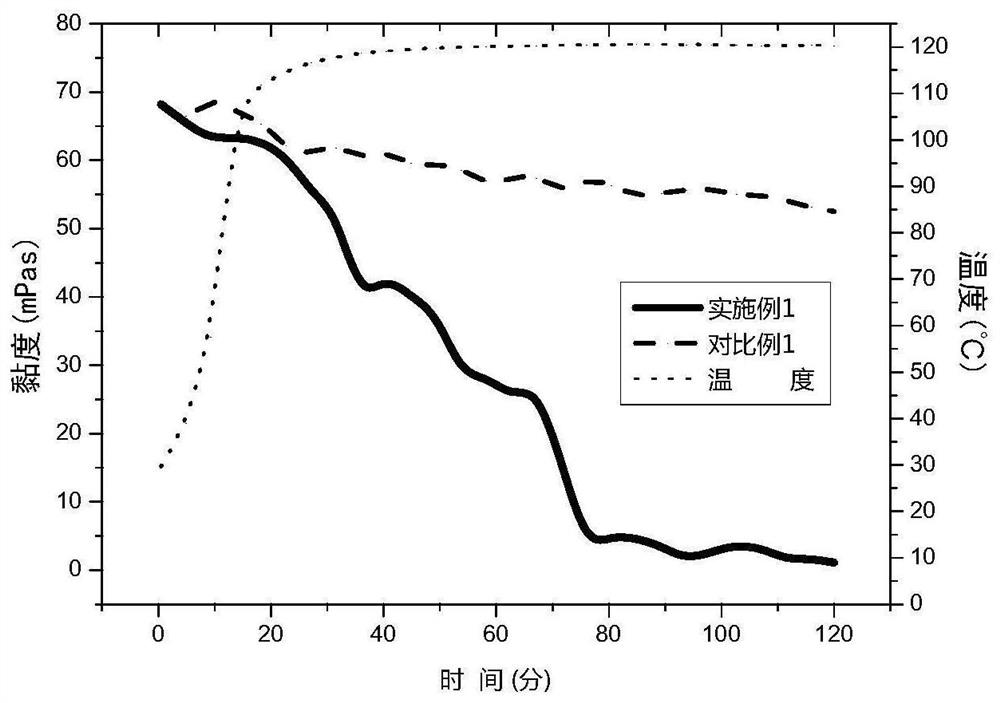

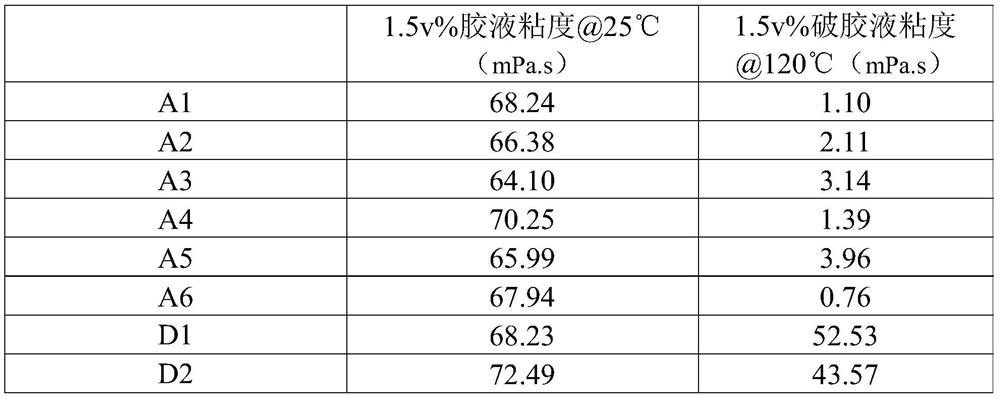

Embodiment 1

[0063] At room temperature, in a 500ml three-neck flask, add 500,000 molecular weight poly-2-acrylamido-2-dimethylpropanesulfonate sodium 5g, deionized water 235g, acrylamide 50g, acrylic acid 24g, potassium chlorate 1g, dissolve evenly , add 80g of ammonium sulfate, fully dissolved to form a clear solution. Nitrogen was bubbled under stirring for 20 minutes. Under nitrogen protection, under the condition of 30°C, 5g of 16wt% sodium bisulfite solution was uniformly added within 6 hours, and the molar ratio of the oxidizing agent gaining electrons to the reducing agent losing electrons was 3.2:1. The system gradually turns white within 10 hours, forming a white emulsion drag reducer A1. After testing, in the drag reducer A1, the oxidant content is 0.22wt%, and the solid content is 18.5wt%. In the acrylamide copolymer, acrylamide The content of the structural unit is 68wt%, and the content of the structural monomer B is 32wt%.

Embodiment 2

[0065] At room temperature, in a 500ml three-necked flask, add 500,000 molecular weight poly 2-acrylamido-2-dimethylpropanesulfonate sodium 5g, deionized water 232.1g, acrylamide 55g, methacrylic acid 22g, potassium chlorate 0.9g , After dissolving evenly, add 80g of ammonium sulfate, fully dissolve to form a clear solution. Nitrogen was bubbled under stirring for 20 minutes. Under nitrogen protection, at 30°C, 5 g of 16% sodium bisulfite solution was evenly added within 6 hours, and the molar ratio of the oxidizing agent gaining electrons to the reducing agent losing electrons was 2.9:1. The system gradually turns white within 10 hours, forming a white emulsion drag reducer A2. After testing, the content of oxidant in drag reducer A2 is 0.19wt%, and the solid content is 19.25wt%. Among acrylamide copolymers, acrylamide The content of the structural unit is 71 wt%, and the content of the structural monomer B is 29 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com