Preparation method of nanoparticle and nanofiber composite stable high internal phase emulsion

A nanofiber and nanoparticle technology, applied in the field of high internal phase emulsion, can solve the problems of oil leakage in demulsification, high cost of natural materials, adverse effects on human health, etc., and achieve safe use, good anti-oxidation performance, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

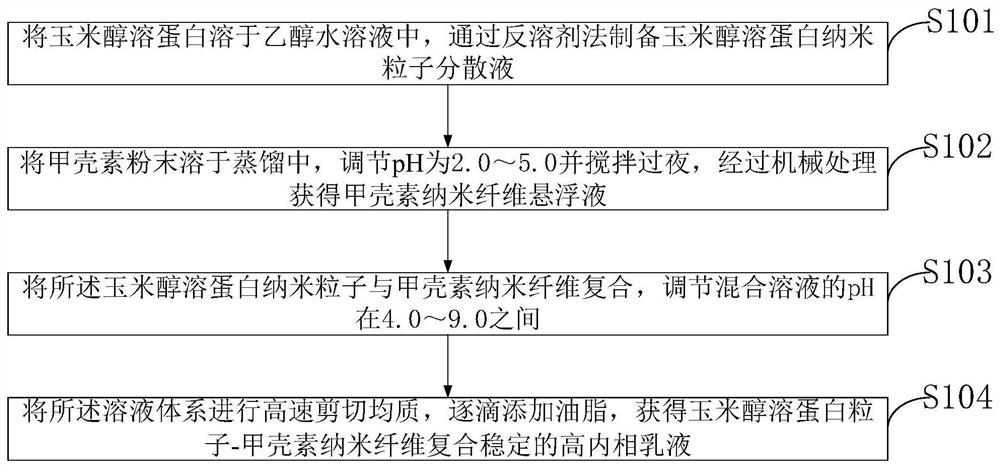

[0051] Such as figure 1 As shown, the present invention provides a method for preparing a zein particle-chitin nanofiber composite stable high internal phase emulsion, comprising the following steps:

[0052] S101, dissolving zein in an aqueous ethanol solution, and preparing a dispersion of zein nanoparticles by an anti-solvent method.

[0053] S102, dissolving the chitin powder in distillation, adjusting the pH to 2.0-5.0 and stirring overnight, and mechanically treating to obtain a suspension of chitin nanofibers.

[0054] S103. Composite the zein nanoparticles and chitin nanofibers, and adjust the pH of the mixed solution to be between 4.0 and 9.0.

[0055] S104, performing high-speed shear homogenization on the solution system, adding oil dropwise to obtain a high internal phase emulsion with zein particles-chitin nanofibers composite and stable.

[0056] The preparation method of the stable high internal phase emulsion of the particle and nanofiber composite provided b...

Embodiment 1

[0059] 1. Dissolve 4 g of zein powder in 100 mL of ethanol solution (75% v / v), and then add the solution to 300 mL of ultrapure water under continuous stirring (800 r / min). After stirring for 15 minutes, the concentration of zein nanoparticles (ZCPs) was 6% w / v by removing ethanol and part of the water in the particle dispersion by using a rotary evaporator. The resulting solution was centrifuged at 1000 rpm for 10 minutes to remove insoluble precipitates.

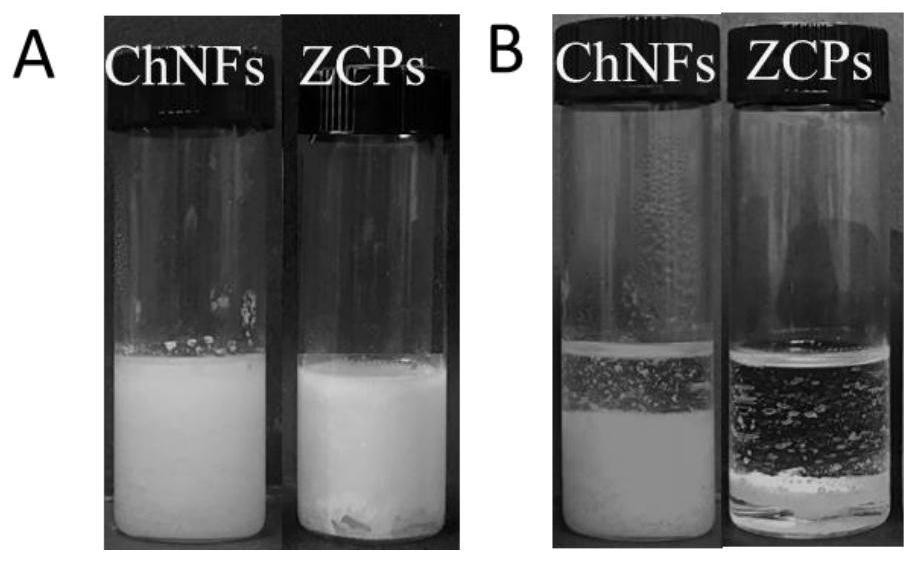

[0060] 2. Disperse 2 g of chitin powder in 200 mL of distilled water, adjust the pH to 2.0-5.0 with HCl, and keep stirring overnight. Then the chitin suspension was homogenized by dynamic high pressure, homogenized 25 times under the condition of 1000bar to obtain the chitin nanofiber suspension (ChNFs) with 0.8% w / w, and dried to a constant weight at a constant temperature of 60°C to determine solids content.

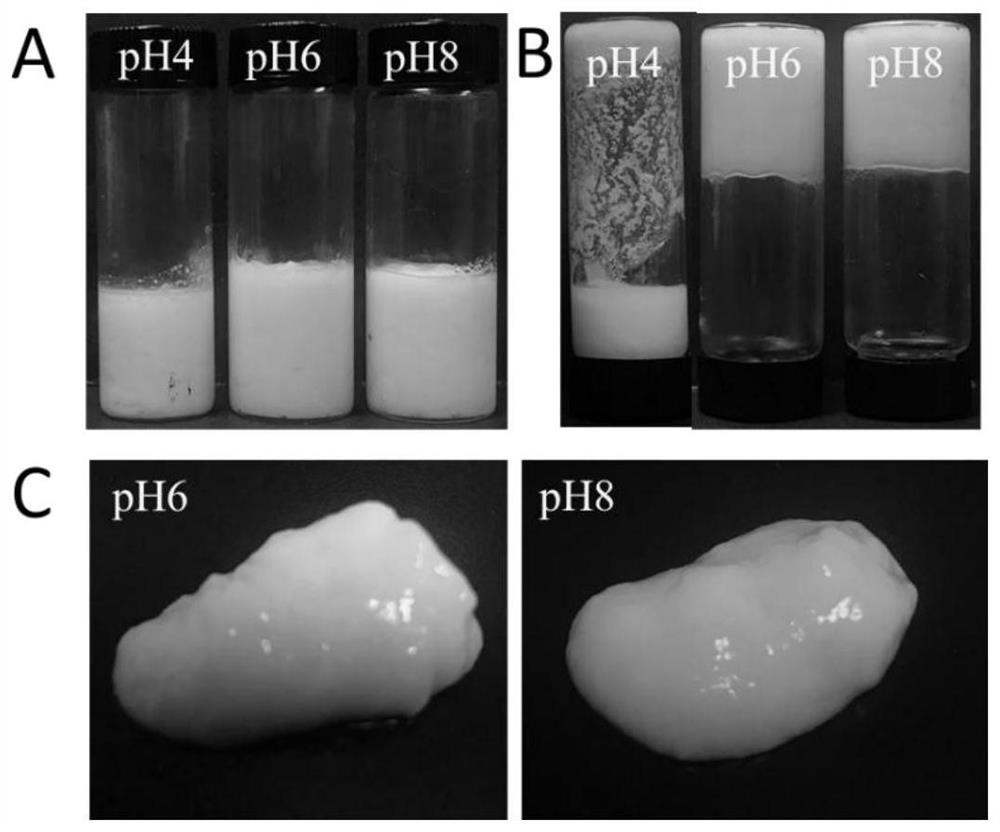

[0061] 3. Mix 2ml of the ZCPs solution obtained in step 1 with 3mL of the ChNFs solution obtained in step 2 an...

Embodiment 2

[0070] 1. Dissolve 4 g of zein powder in 100 mL of ethanol solution (75% v / v), and then add the solution to 300 mL of ultrapure water under continuous stirring (800 r / min). After stirring for 15 minutes, the concentration of zein nanoparticles (ZCPs) was 6% w / v by removing ethanol and part of the water in the particle dispersion by using a rotary evaporator. The resulting solution was centrifuged at 1000 rpm for 10 min to remove insoluble precipitates.

[0071] 2. Disperse 2 g of chitin powder in 200 mL of distilled water, adjust the pH to 2.0-5.0 with HCl, and keep stirring overnight. Then the chitin suspension was homogenized by dynamic high pressure, homogenized 25 times under the condition of 1000bar to obtain the chitin nanofiber suspension (ChNFs) with 0.8% w / w, and dried to a constant weight at a constant temperature of 60°C to determine solids content.

[0072] 3. Add the ChNFs solution obtained in step (2) to the ZCPs solution obtained in step (1) in different volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com