Preparation method and use method of core-shell catalyst for carbon dioxide hydrogenation

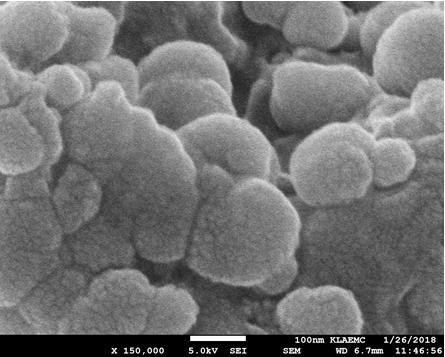

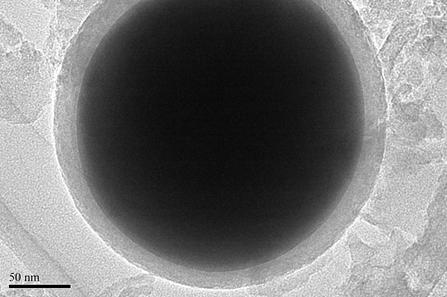

A core-shell structure, carbon dioxide technology, applied in the direction of catalyst activation/preparation, carbon monoxide, physical/chemical process catalysts, etc., can solve the problems of poor thermal stability, easy sintering of copper catalysts, etc., to promote adsorption, and the preparation method is simple, efficient, and good The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Mix 45 g of copper nitrate solution with a mass fraction of 5% and 45 g of a zinc nitrate aqueous solution with a mass fraction of 5%, and stir at room temperature for 30 minutes to obtain a mixed solution A;

[0042] (2) Weigh 36.5 g of cetyltrimethylammonium bromide aqueous solution with a mass fraction of 10%, mix it with 84.6 g of a prepared sodium carbonate aqueous solution with a mass fraction of 5%, and stir at room temperature for 1 hour, Obtain mixed solution B;

[0043] (3) Slowly add the mixed solution A and the mixed solution B into a three-necked flask containing 50 g of water by co-precipitation method under stirring at 60 °C. The pH value of the solution in the flask is about 8, until the dropwise addition of the mixed solution A is completed, continue to stir for 2 hours, then stop heating, cool to room temperature, then repeatedly wash with deionized water, suction filter until the filtrate is neutral, and the filter cake passes through After dryin...

Embodiment 2

[0048] (1) Mix 45 g of copper nitrate solution with a mass fraction of 5% and 45 g of a zinc nitrate aqueous solution with a mass fraction of 5%, and stir at room temperature for 30 minutes to obtain a mixed solution A;

[0049] (2) Weigh 18.3 g of a 10% polyvinylpyrrolidone aqueous solution, mix it with 110.1 g of a prepared 5% sodium carbonate aqueous solution, and stir at room temperature for 1 hour to obtain a mixed solution B;

[0050] (3) Slowly add mixed solution A and mixed solution B into a three-necked flask containing 40 g of water by co-precipitation method under stirring at 50 °C. The pH value of the solution in the flask is about 8, until the dropwise addition of the mixed solution A is completed, continue to stir for 2 hours, then stop heating, cool to room temperature, then repeatedly wash with deionized water, suction filter until the filtrate is neutral, and the filter cake passes through After drying at 80°C for 4 hours, continue drying at 120°C for 2 hours ...

Embodiment 3

[0055] (1) Mix 45 g of copper nitrate solution with a mass fraction of 5% and 45 g of a zinc nitrate aqueous solution with a mass fraction of 5%, and stir at room temperature for 30 minutes to obtain a mixed solution A;

[0056] (2) Weigh 30.4 g of an aqueous solution of polyethylene glycol with a mass fraction of 10%, mix it with 63.9 g of a prepared aqueous sodium carbonate solution with a mass fraction of 5%, and stir at room temperature for 1 hour to obtain a mixed solution B;

[0057] (3) Slowly add mixed solution A and mixed solution B into a three-necked flask containing 40 g of water by co-precipitation method under stirring at 60 °C. The pH value of the solution in the flask is about 8, until the dropwise addition of the mixed solution A is completed, continue to stir for 2 hours, then stop heating, cool to room temperature, then repeatedly wash with deionized water, suction filter until the filtrate is neutral, and the filter cake passes through After drying at 80°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com