Method for preparing high-purity cupric oxide powder from acid cupriferous waste liquid

A technology of copper oxide powder and waste liquid, which is applied in the direction of copper oxide/copper hydroxide, etc., can solve the problems of high-purity copper oxide powder filtration and washing difficulties, and achieve the effect of eliminating the difficulty of re-filtration, simple process and eliminating the difficulty of washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

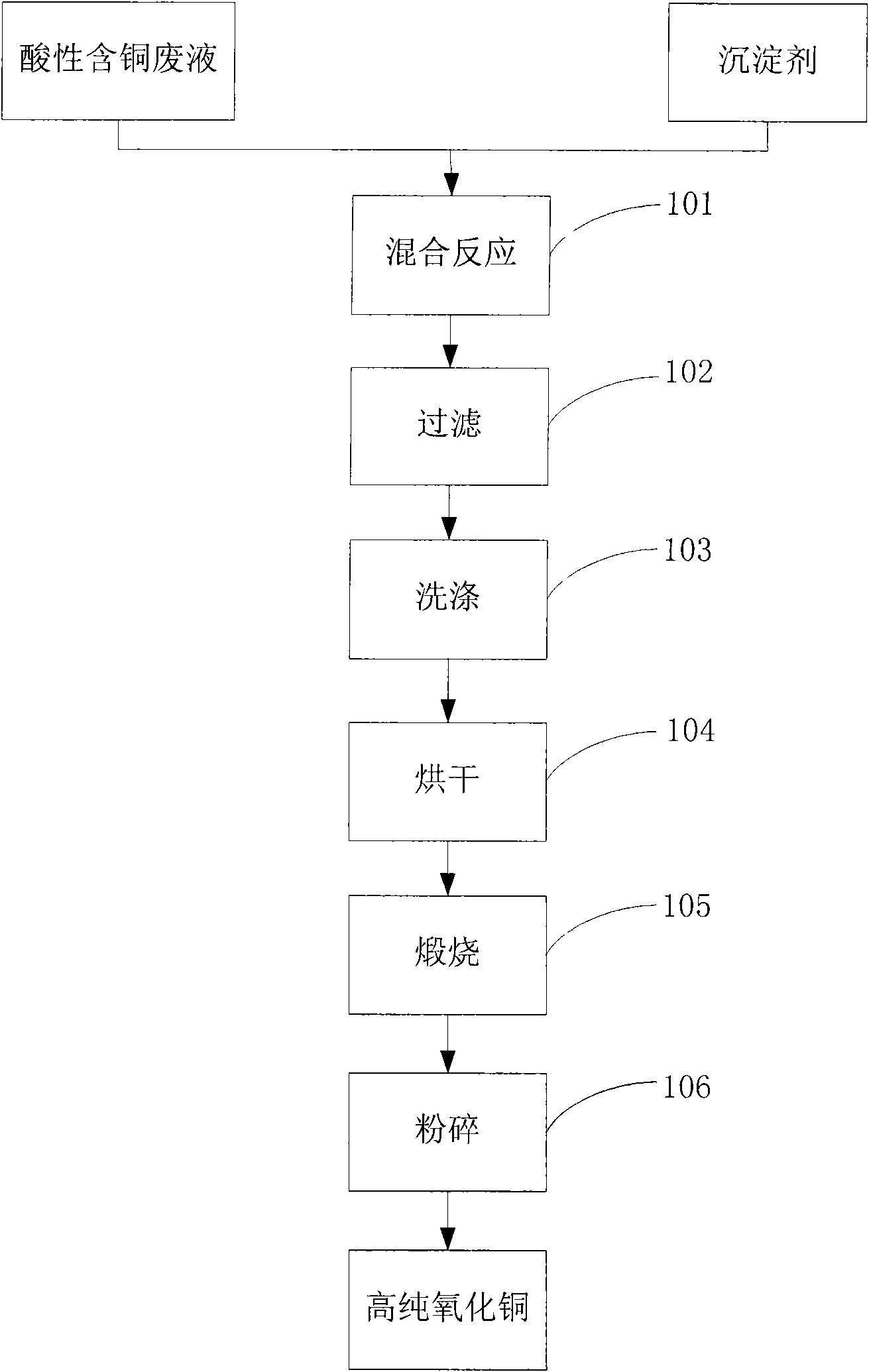

Image

Examples

Embodiment 1

[0037] Take the acidic etching waste liquid (mainly containing Cu 2+ : 130-140g / L, HCl: 80-110g / l, NaClO: 4-6g / l) in a beaker, mix and react with precipitant under high-speed stirring state (mass percentage is 30% sodium hydroxide and 30% % sodium carbonate mixed solution), the pH value of the mixture after the reaction was 11.0 ± 0.5. The resulting mixture was transferred to a sand core funnel for suction filtration, then washed with water, then washed with a mixed aqueous solution of 1% by mass of ammonium carbonate and ammonium bicarbonate, and finally washed with water. The washed filter cake is dried at 50°C, then calcined at 400°C, and finally crushed to obtain high-purity copper oxide powder.

Embodiment 2

[0039] Take the acidic etching waste liquid (mainly containing Cu 2+ : 130-140g / L, HCl: 80-110g / l, NaClO: 4-6g / l) in a beaker, mix and react with precipitant under high-speed stirring state (mass percentage is 40% potassium hydroxide and 10 % ammoniacal liquor), the pH of the mixture was 9.0 ± 0.5 after the reaction. The resulting mixture was transferred to a sand core funnel for suction filtration, then washed with water, then washed with 20% by mass ammonium nitrate aqueous solution, and finally washed with water. The washed filter cake is dried at 60°C, then calcined at 800°C, and finally crushed to obtain high-purity copper oxide powder.

Embodiment 3

[0041] Take the acidic etching waste liquid (mainly containing Cu 2+ : 130-140g / L, HCl: 80-110g / l, NaClO: 4-6g / l) in a beaker, mixed with a precipitant under high-speed stirring to react (sodium hydroxide solution with a mass percentage of 30%) , the pH of the mixture was 11.0±0.5 after the reaction. Transfer the reaction mixture to a sand core funnel for suction filtration, then wash with water, then with 0.1% by mass aqueous ammonia solution, and finally with water. The washed filter cake is dried at 50°C, then calcined at 900°C, and finally crushed to obtain high-purity copper oxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com