Method for preparing graphene/copper/cuprous oxide composite powder through low-energy ball mill

A cuprous oxide and composite powder technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of destroying the hexagonal structure of graphene carbon atoms, lengthy and cumbersome process, and difficulty in mass production , to achieve good powder dispersion effect, simple process steps and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Graphene with a purity of 99.0wt% is immersed in a mixed acid with a volume ratio of hydrochloric acid and nitric acid of 1:1 for 1.5h. After cleaning and drying, it is ultrasonically dispersed in deionized water for 40min to obtain a mass concentration of 0.3wt%. Graphene dispersion liquid;

[0028] (2) Copper powder is placed in the polytetrafluoroethylene ball mill jar that zirconia ball is housed, and ball material ratio is 1:1, carries out pre-ball milling 1h under the condition of 30r / min and mixes with graphene dispersion liquid, described The quality of graphene accounts for 1wt% of the copper powder mass, and its pH is adjusted to 3.0 by using 10wt% dilute hydrochloric acid, and then the mixed slurry is obtained after secondary ball milling for 1h under the condition of 30r / min;

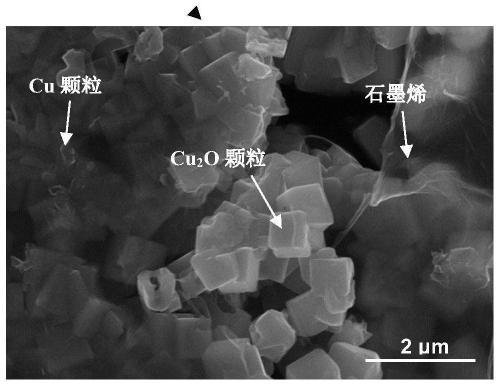

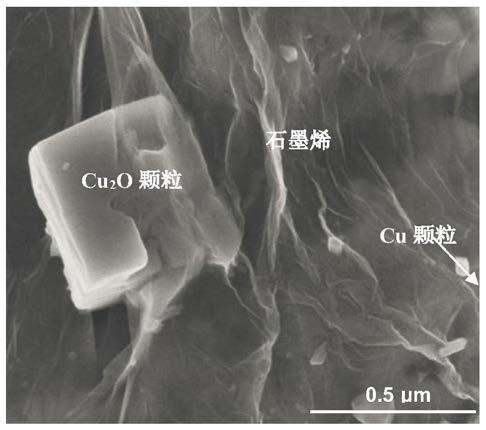

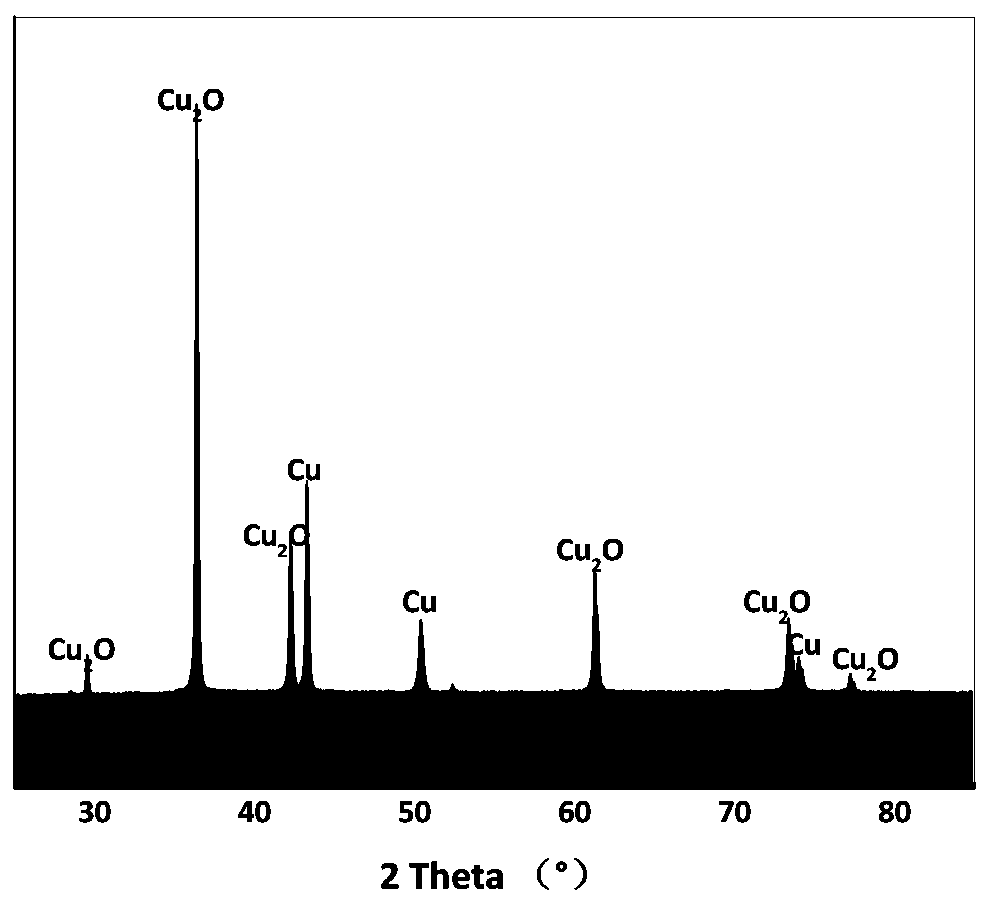

[0029] (3) The mixed slurry was diluted to neutral with deionized water, then stirred and reacted at 70° C. for 15 minutes, and the graphene / copper / cuprous oxide composite powder ...

Embodiment 2

[0031] (1) the graphene that purity is 99.0wt% is soaked 3h in the mixed acid that hydrochloric acid and nitric acid volume ratio are 3:1, after cleaning, drying, obtain mass concentration after ultrasonic dispersion 60min in deionized water and be 0.5wt% Graphene dispersion;

[0032] (2) Copper powder is placed in the polytetrafluoroethylene ball mill jar that zirconia ball is housed, and ball material ratio is 2:1, carries out pre-ball milling 1.5h under the condition of 60r / min and mixes with graphene dispersion liquid, so The quality of the graphene accounts for 3wt% of the copper powder quality, adopting 10wt% dilute hydrochloric acid to adjust its pH to 4.0, and then performing secondary ball milling for 1.5h under the condition of 60r / min to obtain the mixed slurry;

[0033] (3) Dilute the mixed slurry to neutral with deionized water, then stir and react at 80°C for 20 minutes, and after suction filtration and freeze-drying, the graphene / copper / cuprous oxide composite p...

Embodiment 3

[0035] (1) the graphene that purity is 99.0wt% is soaked 3h in the mixed acid that hydrochloric acid and nitric acid volume ratio are 1:3, after cleaning, drying, obtain mass concentration after ultrasonic dispersion 80min in deionized water and be 0.8wt% Graphene dispersion;

[0036] (2) Copper powder is placed in the agate ball mill jar that agate ball is housed, and ball-to-material ratio is 3:1, carries out pre-ball milling 1.5h under the condition of 100r / min and mixes with graphene dispersion liquid after, described graphene The mass accounts for 3wt% of the copper powder mass, and the pH is adjusted to 4.0 by using 10wt% dilute hydrochloric acid, and then the mixed slurry is obtained after secondary ball milling under the condition of 100r / min for 8.0h;

[0037] (3) Dilute the mixed slurry to neutral with deionized water, then stir and react at 80°C for 20 minutes, and after suction filtration and freeze-drying, the graphene / copper / cuprous oxide composite powder is obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com