Method for preparing carbon particles/copper composite materials

A composite material and particle technology, applied in the field of preparing carbon-based particles/copper composite materials, can solve the problems of poor compatibility, difficulty in achieving compatibility of carbon-based particles and copper, etc., and achieve the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The first method of preparing the composite material according to the present invention is described below.

[0032] First, a solution of a polymer organic compound having a carbon backbone and a copper precursor in a solvent is mixed with a dispersion of carbon-based particles in a first dispersion medium to prepare a mixture (step 1).

[0033] The polymeric organic compound has a carbon backbone and may preferably include, but is not limited to, polyvinylpyrrolidone and polyvinyl alcohol, preferably in single or combined form, as long as the compound is soluble in a solvent.

[0034] The copper precursor may include any type of copper precursor as long as the copper precursor can form copper(I) oxide by a reducing agent as described below, such as i) a copper carboxyl compound of formula 1, or ii) The carboxyl group-containing compound of the general formula 2 and a copper salt.

[0035]

[0036] (R 1 -COO) 2 Cu

[0037] where R 1 is an alkyl group containing 1...

Embodiment 1

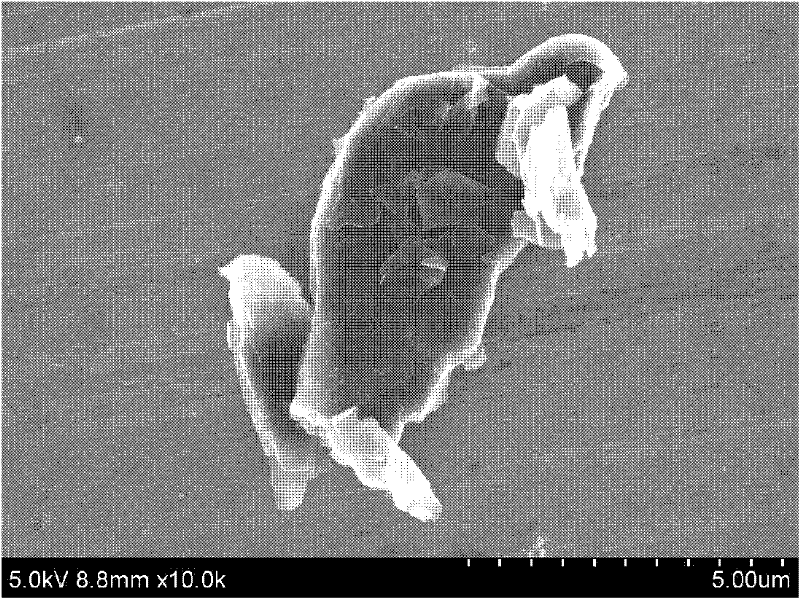

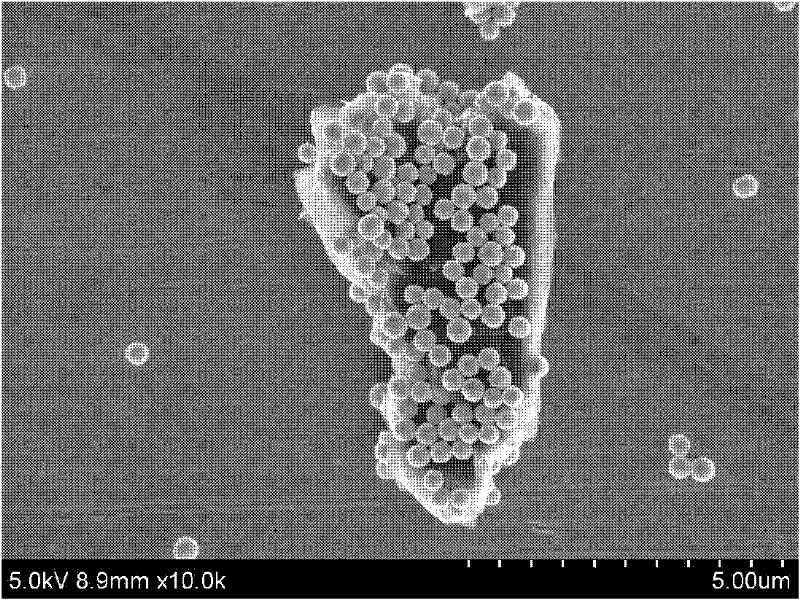

[0057] (1) 3 mg of graphite having an average particle size of 7 μm was added to 10 ml of ethylene glycol and subjected to ultrasonic treatment for 1 hour to prepare a dispersion. 50 mg of copper(II) acetate and 200 mg of polyvinylpyrrolidone (PVP) were dissolved in 5 ml of water, and then added to the dispersion liquid prepared above, followed by stirring.

[0058] (2) 15mg of N 2 H 5 OH was dissolved in 5 ml of water and added dropwise to the mixture obtained according to step 1. The particles were separated from the mixture, washed twice with water and dried.

[0059] (3) After the temperature was raised to 700°C at a temperature increase rate of 40°C / min, the particles obtained according to step 2 were sintered for 5 minutes in a nitrogen atmosphere.

Embodiment 2

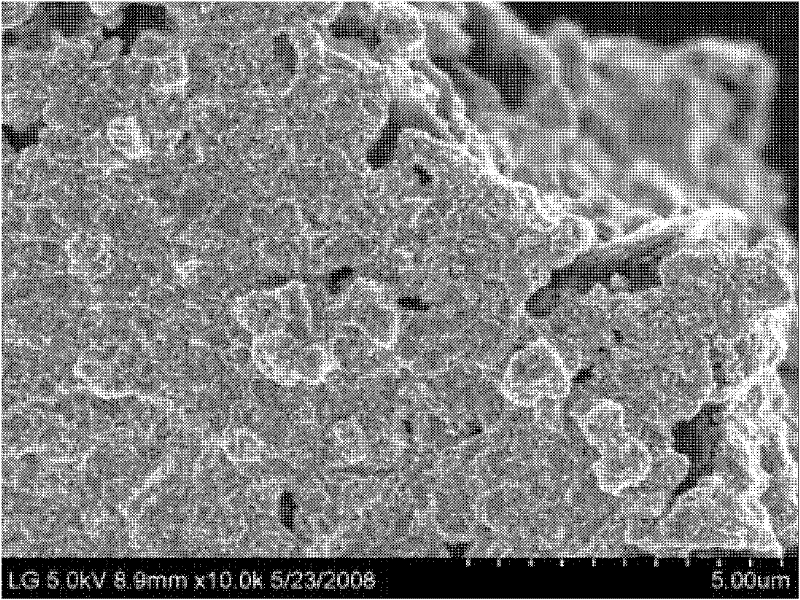

[0061] The particles prepared according to steps 1 and 2 of Example 1 were redispersed in water to which excess NaBH was added 4 aqueous solution. The particles were isolated from the dispersion, washed twice with water and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com