Copper oxide nano-belt and preparation method thereof

A technology of nanobelt and copper oxide, which is applied in the field of nanomaterials and can solve the problems of few reports on copper oxide ribbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

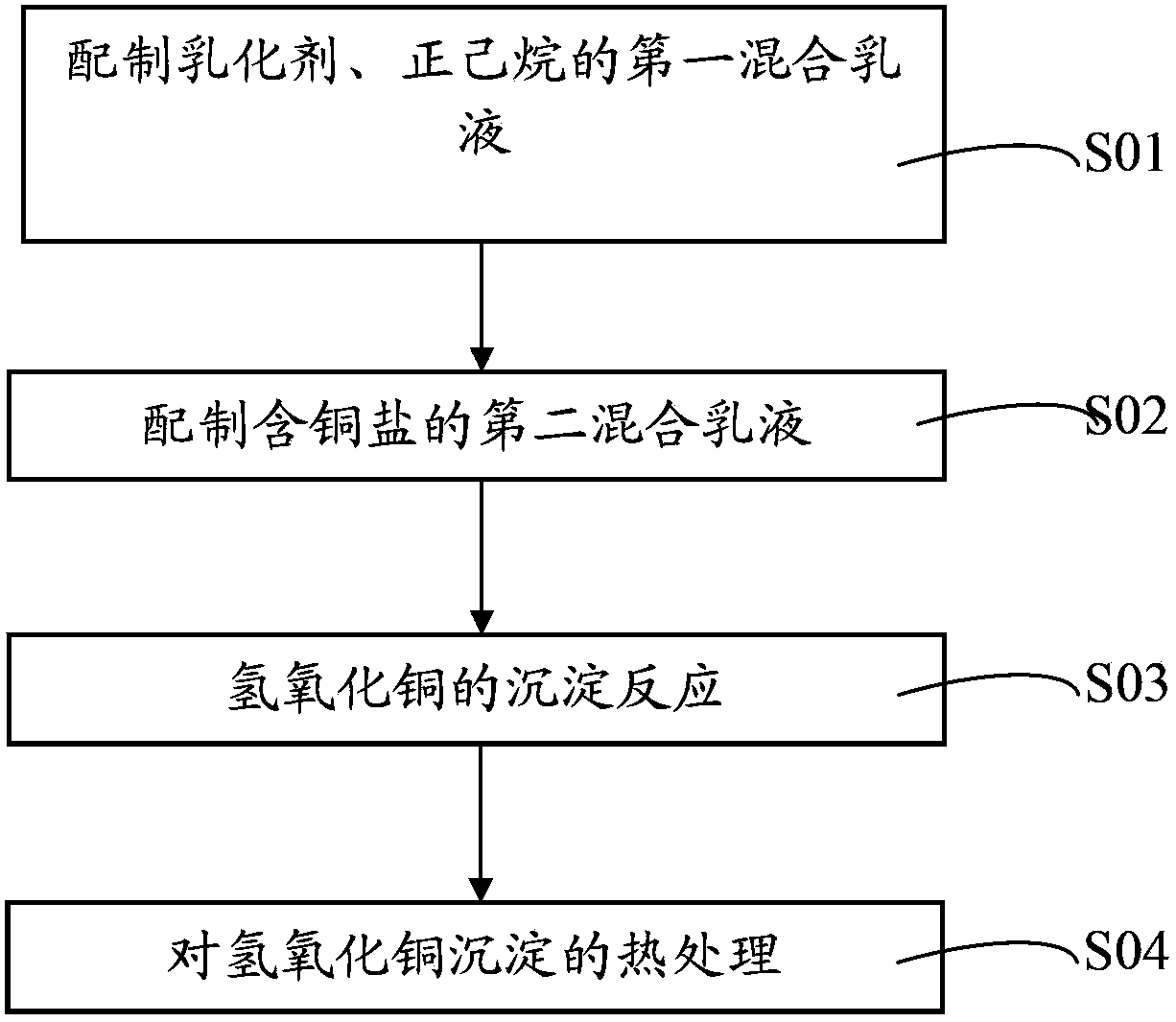

[0022] The embodiment of the present invention provides a method for preparing copper oxide nanoribbons with simple process and easy controllable conditions. The preparation method technological process of this copper oxide nanobelt is as follows figure 1 shown, including the following steps:

[0023] Step S01. Prepare the first mixed emulsion of emulsifier and n-hexane: mix the emulsifier and n-hexane and perform emulsification treatment to prepare the first mixed emulsion; wherein, the ratio of emulsifier and n-hexane is 1.5g:60 ~90mL;

[0024] Step S02. Prepare the second mixed emulsion containing copper salt: mix the aqueous solution of copper salt with the first mixed emulsion prepared in step S01, and then perform secondary emulsification treatment to prepare the second mixed emulsion;

[0025] Step S03. Precipitation reaction of copper hydroxide: add water to the second mixed emulsion prepared in step S02 for mixing, and add ammonia water dropwise, adjust the pH of th...

Embodiment 1

[0044] A copper oxide nanobelt and a preparation method thereof. The preparation method is as follows:

[0045] (1) Dissolve 1.5g of Span80 in 72mL of n-hexane, emulsify and mix evenly at a speed of 10000rpm, and record it as the first mixed emulsion;

[0046] (2) Add 18mL of 1.0M CuSO 4 Add the solution to the first mixed emulsion prepared in step (1), continue to emulsify at high speed (10000rpm) for 1min, and record the obtained mixed solution as the second mixed emulsion;

[0047] (3) Quickly add the second mixed emulsion prepared in step (2) to 126mL of deionized water, stir vigorously and dropwise add 0.5M ammonia water to adjust the pH value to about 4, continue stirring for 3 hours, and filter the formed copper hydroxide precipitate, Wash with deionized water and ethanol several times to remove Span80, n-hexane and unreacted raw materials, and dry the washed copper hydroxide precipitate at 80°C for 12 hours in vacuum;

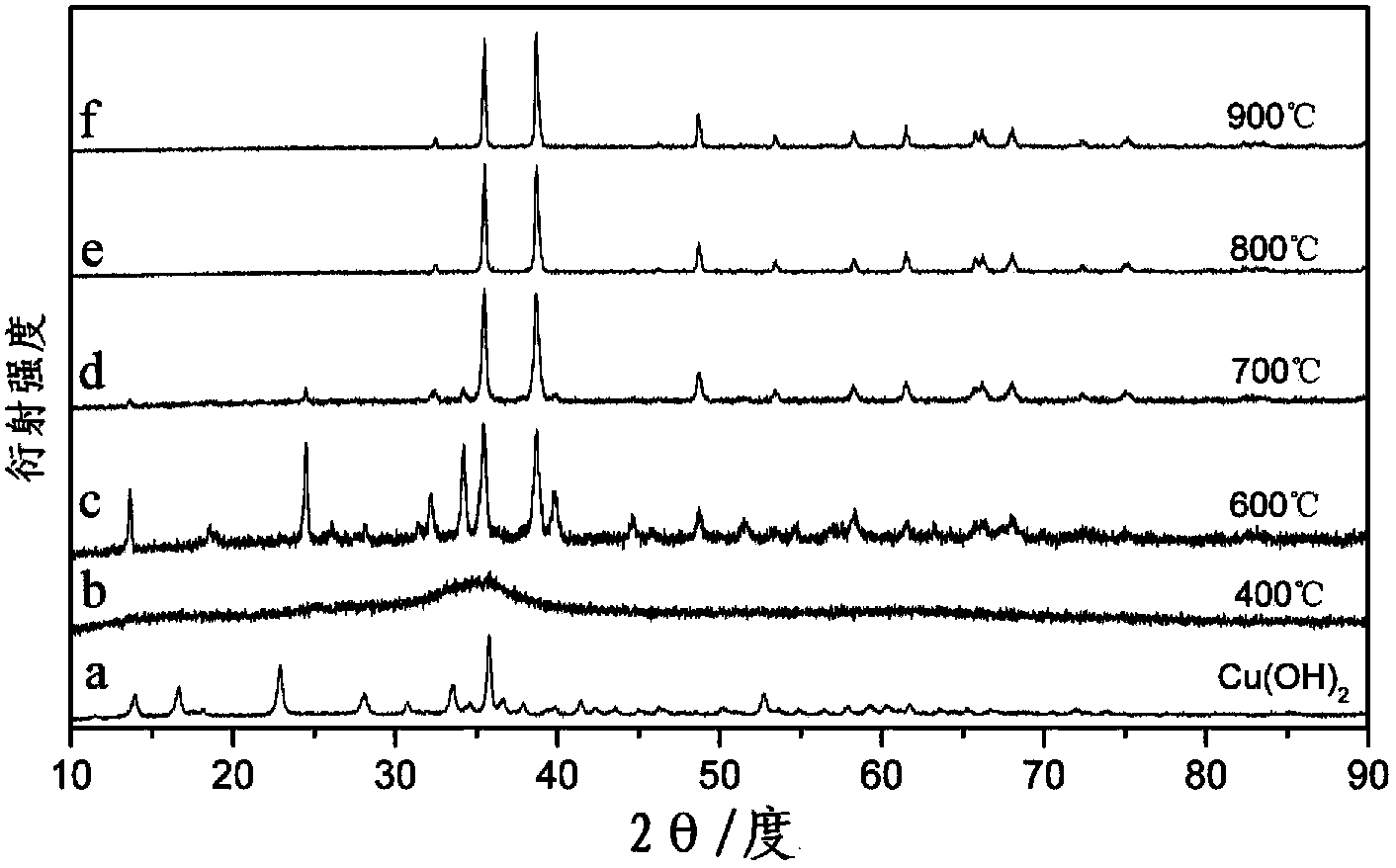

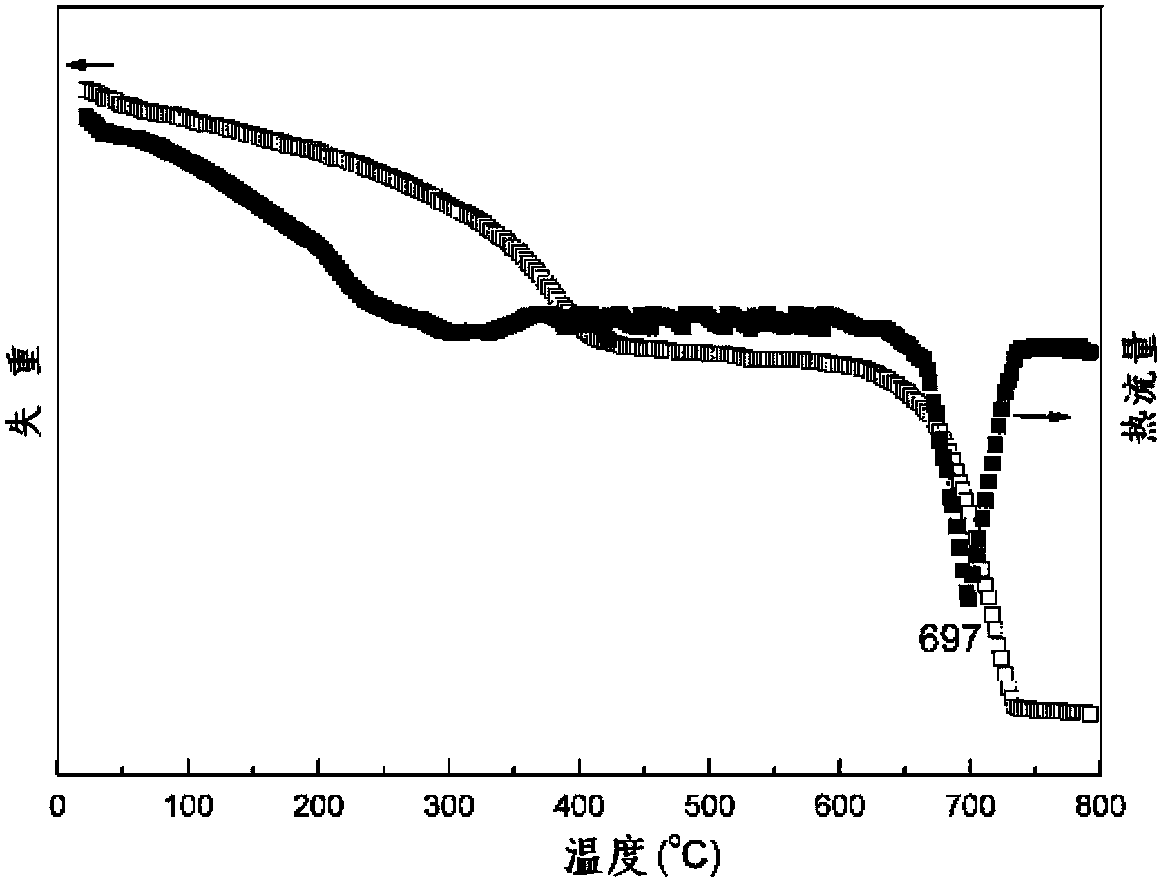

[0048] (4) Calcining the dried copper hydroxid...

Embodiment 2

[0050] A copper oxide nanobelt and a preparation method thereof. The preparation method is as follows:

[0051] Steps (1) to (3) refer to steps (1) to (3) in Example 1;

[0052] Step (4): calcining the dried copper hydroxide precipitate at 600° C. for 0.5-1.0 hour to obtain a copper oxide nanobelt product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com