Preparation method of octahedral cuprous oxide catalyst for synthesizing methyl chlorosilane monomers

A cuprous oxide and octahedral technology, which is applied in the field of preparation of octahedral cuprous oxide catalysts, can solve the problems of high cost, poorly controllable morphology, and difficulty in large-scale generation, and achieves low cost, simple preparation process, and controllability. Conditions and means easy to implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

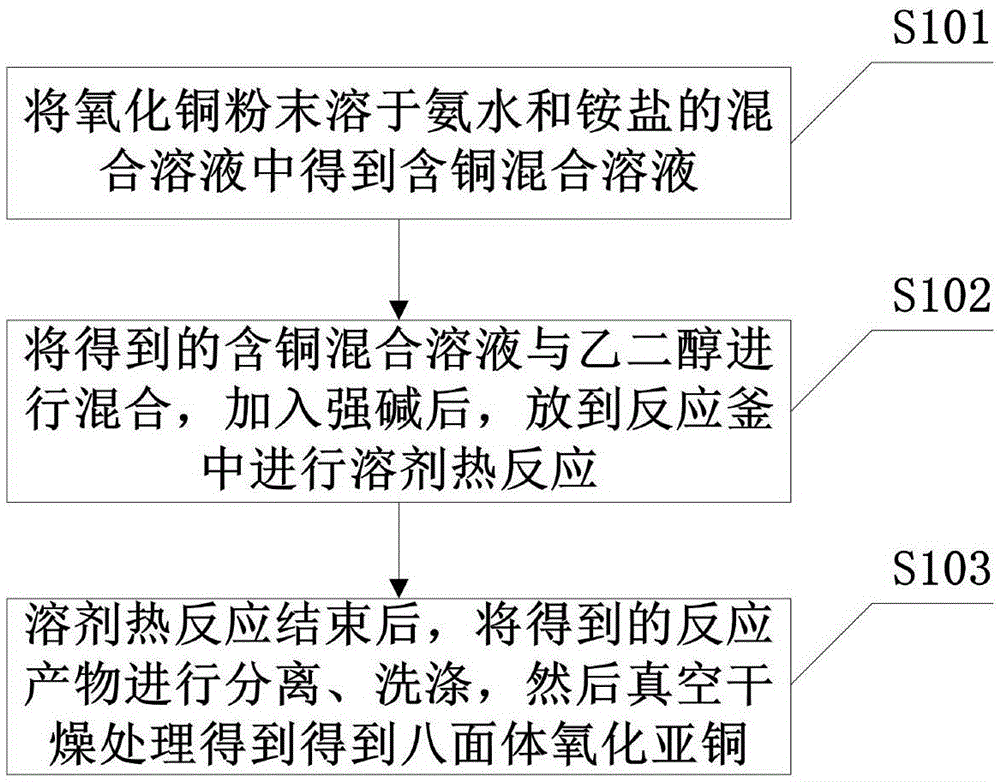

[0033] See figure 1 As shown, the preparation method of the octahedral cuprous oxide catalyst provided in this embodiment includes:

[0034] Step 101: dissolving copper oxide powder in a mixed solution of ammonia water and ammonium salt to obtain a copper-containing mixed solution;

[0035] Step 102: Mix the obtained copper-containing mixed solution with ethylene glycol, add a strong base, and put it into a reaction kettle for solvothermal reaction;

[0036] Step 103: After the solvothermal reaction is completed, extract the obtained reaction product to obtain octahedral cuprous oxide. Extracting the obtained reaction product includes separating, washing and then vacuum drying the obtained reaction product. The specific separation, washing and vacuum drying techniques can be selected according to specific conditions.

[0037] In this example, copper oxide powder is used as the copper source, no structure-directing agent is added, and octahedral cuprous oxide is synthesized ...

Embodiment 2

[0047] In order to better understand the present invention, this embodiment further illustrates the present invention in conjunction with a specific example:

[0048] Take 0.6g copper oxide powder and dissolve in 9.0ml ammonia water containing ammonium carbonate (33.3wt%) to form a mixed solution. Then add 30.0ml of ethylene glycol (the volume ratio of the mixed solution to ethylene glycol is 0.3, and the concentration of copper ions is 0.2mol / l), stir well and add 0.8g of sodium hydroxide (0.5mol / l), then mix the above The solution was transferred to a 100ml stainless steel hydrothermal kettle, heated to 135°C and kept for 10h. After the reaction, the product was filtered, washed, and vacuum-dried to obtain a powder product.

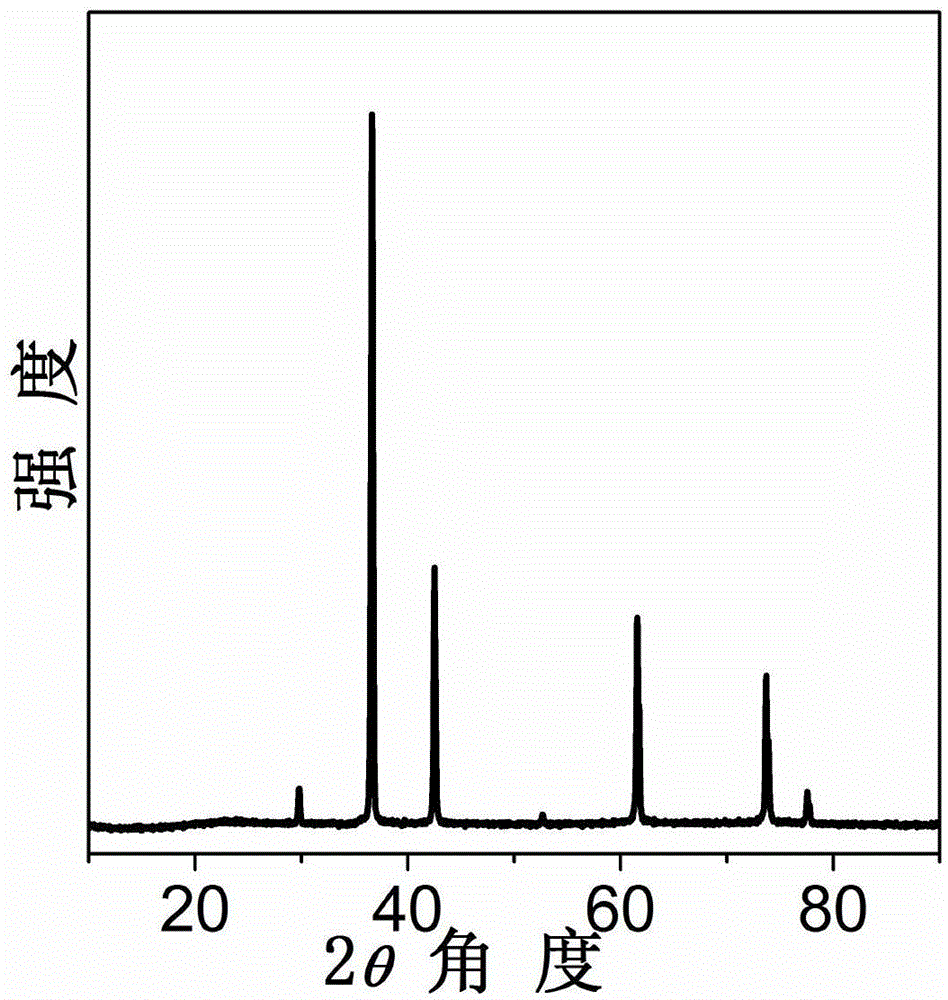

[0049] The product obtained after the above drying was subjected to XRD test on a D / max-rB multifunctional X-ray diffractometer produced by Shimadzu Corporation of Japan. figure 2 It is the XRD spectrum pattern of the powder product that embodiment 1 ...

Embodiment 3

[0052] In order to better understand the present invention, this embodiment further illustrates the present invention in conjunction with a specific example:

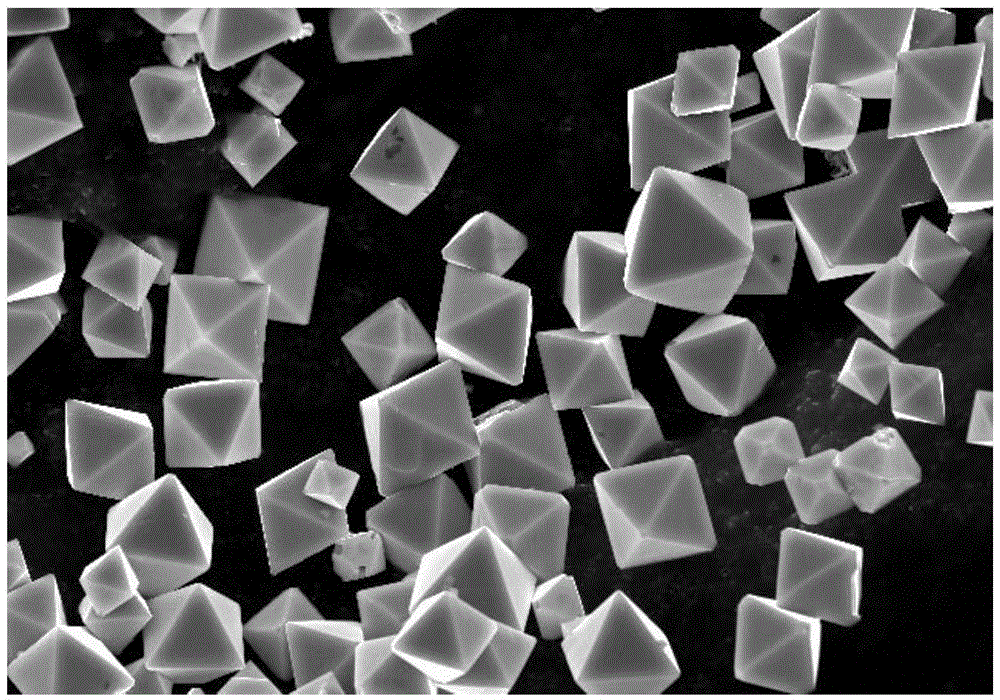

[0053] Take 0.2g of copper oxide powder and dissolve in 5.0ml of ammonia water containing ammonium carbonate (33.3wt%) to form a mixed solution. Then add 50.0ml of ethylene glycol (the volume ratio of the mixed solution to ethylene glycol is 0.1, and the concentration of copper ions is 0.05mol / l), stir well and add 0.2g of sodium hydroxide (0.1mol / l), then mix the above The solution was transferred to a 100ml stainless steel hydrothermal kettle, heated to 180°C and kept for 6 hours. After the reaction, the product was filtered, washed, and vacuum-dried to obtain a powder product. The XRD spectrum confirmed that the product was cubic cuprous oxide. Scanning electron micrographs show that the cuprous oxide powder is octahedral in shape with a size of 5-8 μm. Transmission electron microscope photos further confirm that c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com