Divalent metal ion pre-embedded layered vanadium oxide nanometer material as well as preparation method and application thereof

A technology of divalent metal ions and vanadium oxides, which is applied in the field of nanomaterials and electrochemistry, can solve the problems of unreported research work on preparation methods, achieve good cycle stability, low raw material prices, and facilitate market promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

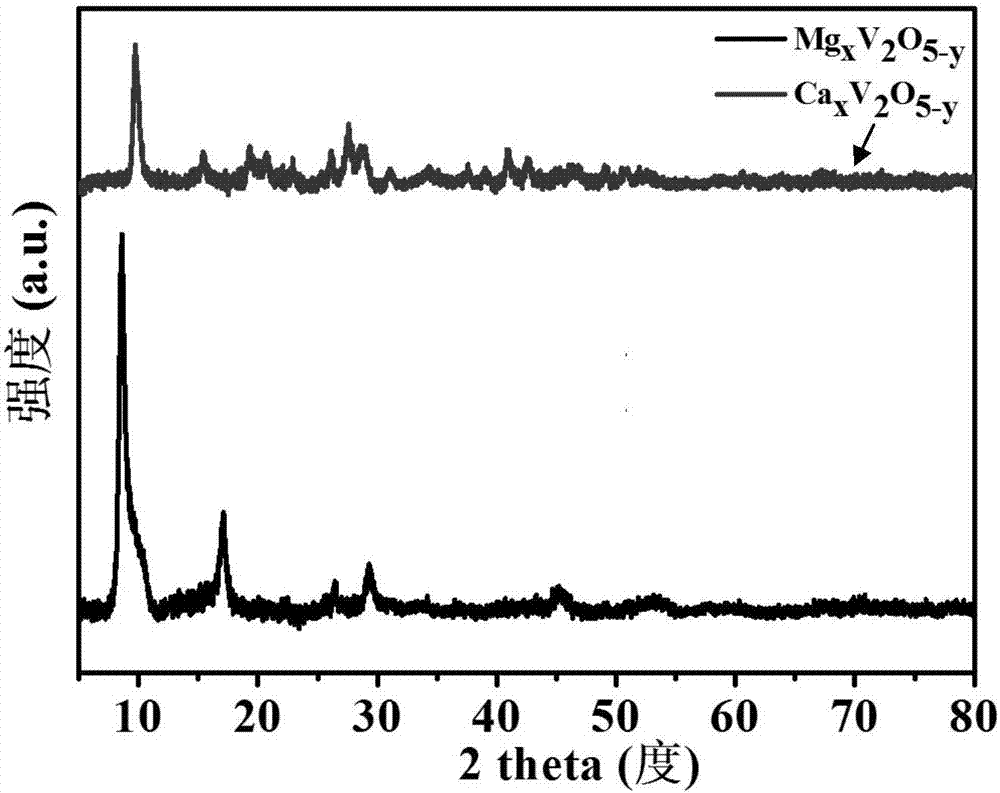

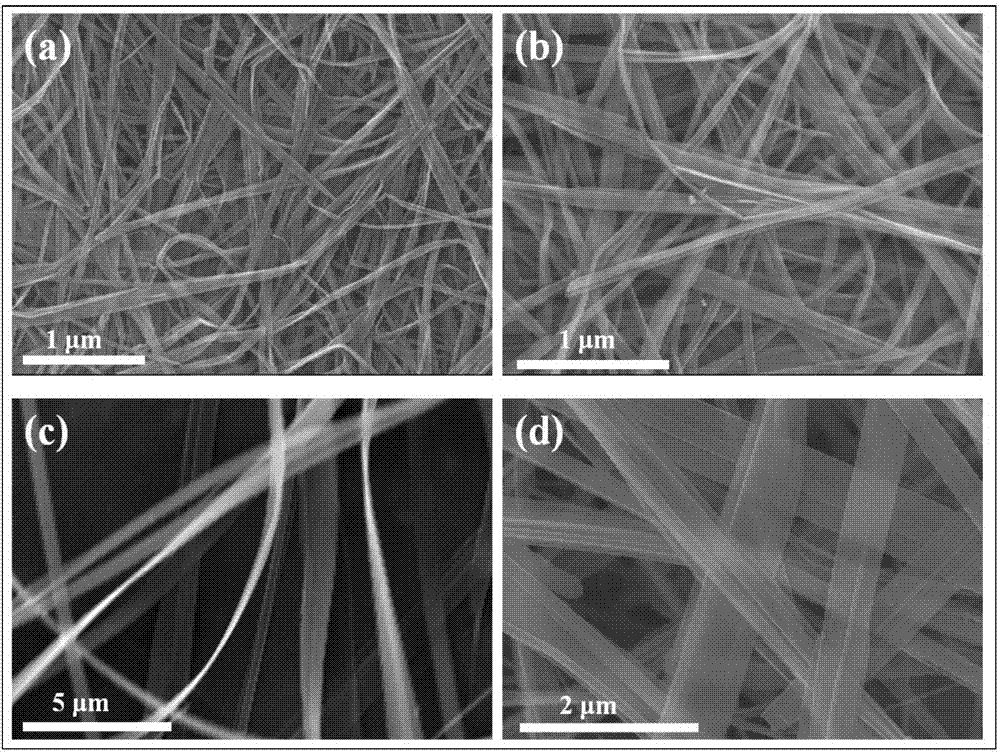

[0030] Mg x V 2 o 5-y The preparation method of nanoribbon material, it comprises the steps:

[0031] 1) Weigh 4 parts of 0.364g V respectively 2 o 5 Add it to 30ml of deionized water, and add 5ml of 30% H 2 o 2 solution, magnetically stirred for half an hour to obtain an orange-red clear solution;

[0032] 2) Weigh 50mmol, 100mmol, 150mmol, and 200mmol MgCl 2 ·6H 2 0, add respectively in the orange-red clear solution in step 1) while magnetic stirring, will be accompanied by violent exothermic reaction, can produce a large amount of orange-red flocculent precipitates, continue to stir for 2~4 hours;

[0033] 3) Transfer the suspension containing flocculent precipitate obtained in step 2) to a 50ml reactor, and heat it at 200°C for 4 days. Then take it out and cool it down to room temperature naturally to obtain dark green, yellow, orange red and red products respectively;

[0034] 4) Pour the product of step 3) into a beaker, mash it, add 30-50ml of deionized water,...

Embodiment 2

[0040] Ca x V 2 o 5-y A preparation method for a nanowire material, comprising the steps of:

[0041] 1) Weigh 0.364g V 2 o 5 Add it to 30ml of deionized water, and add 5ml of 30% H 2 o 2 solution, magnetically stirred for half an hour to obtain an orange-red clear solution;

[0042] 2) Weigh 100mmol CaCl 2 , and add it into the orange-red clear solution in step 1) while magnetically stirring, it will be accompanied by a violent exothermic reaction, and a large amount of orange-red flocculent precipitates will be produced. Stirring was continued for 2-4 hours.

[0043] 3) Transfer the suspension containing flocculent precipitate obtained in step 2) to a 50ml reactor, and heat it at 200°C for 4 days. Then take out and cool to room temperature naturally to obtain orange-red product;

[0044] 4) Pour the product of step 3) into a beaker, mash it, add 30-50ml of deionized water, and stir magnetically to form a uniform suspension;

[0045] 5) The suspension obtained in s...

Embodiment 3

[0048] Sr x V 2 o 5-y The preparation method of nanowire, it comprises the steps:

[0049] 1) Weigh 0.364g V 2 o 5 Add it to 30ml of deionized water, and add 5ml of 30% H 2 o 2 solution, magnetically stirred for half an hour to obtain an orange-red clear solution;

[0050] 2) Weigh 100mmol SrCO 3 Add it into the orange-red clear solution in step 1) while magnetically stirring, and the solution will turn into light brown with a violent exothermic reaction. Continue to stir for 2 to 4 hours to obtain a brown clear solution.

[0051] 3) Transfer the suspension containing flocculent precipitate obtained in step 2) to a 50ml reactor, and heat it at 200°C for 4 days. Then take out and naturally cool to room temperature to obtain a dark green product;

[0052] 4) Pour the product of step 3) into a beaker, mash it, add 30-50ml of deionized water, and stir magnetically to form a uniform suspension;

[0053] 5) The suspension obtained in step 4) is subjected to centrifugal was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com