Preparation method of composite high-magnification silicon-based material, cathode material and lithium battery

A technology of silicon-based composite materials and negative electrode materials, which is applied in the field of materials, can solve the problems of cumbersome preparation methods, large specific surface area of materials, and low first effect of negative electrode materials, and achieve simple and easy preparation methods, excellent rate performance, and good cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

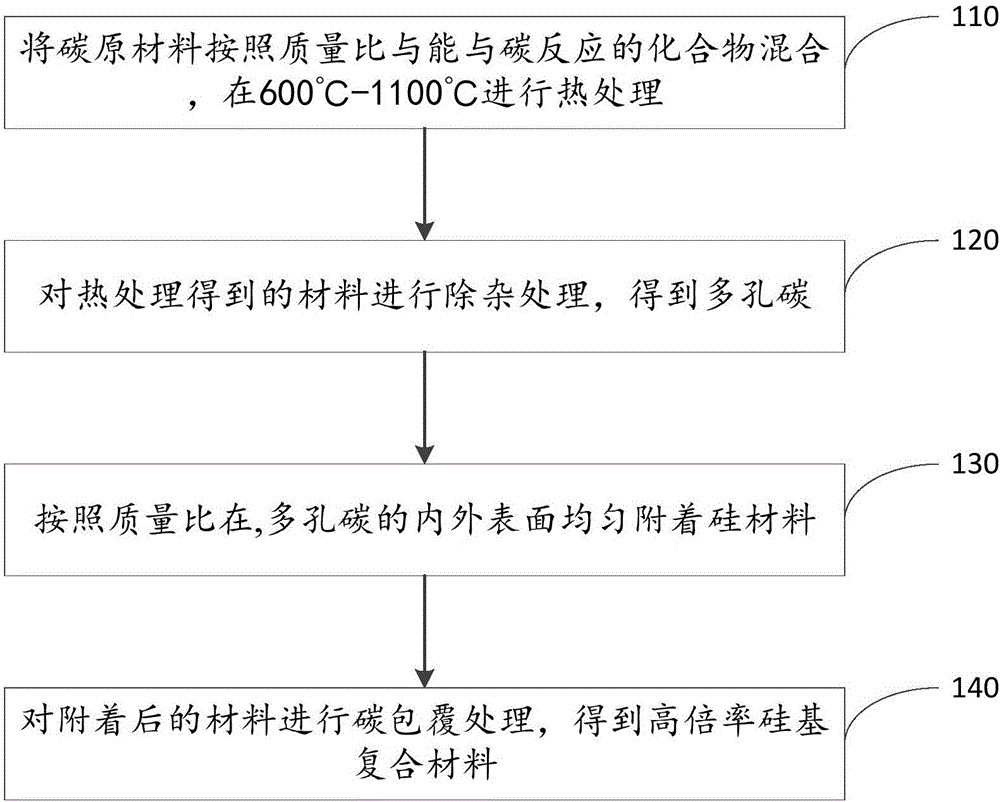

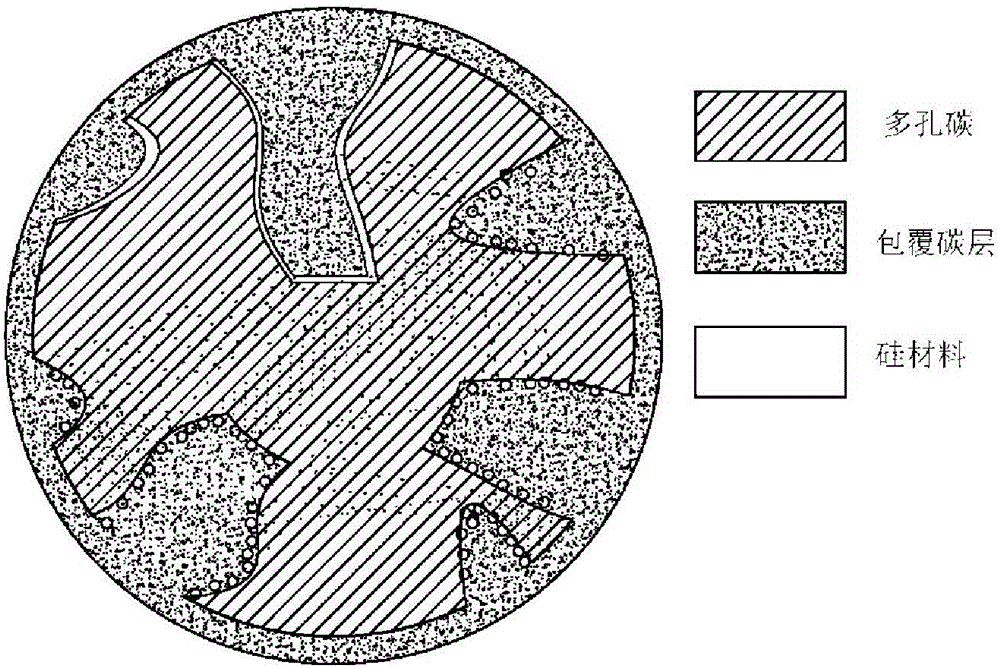

[0045] Embodiment 1 of the present invention provides a method for preparing a high-magnification silicon-based composite material. Such as figure 1 Shown, this preparation method comprises the steps:

[0046] Step 110, mixing the carbon raw material with a compound capable of reacting with carbon according to the mass ratio, and performing heat treatment at 600°C-1100°C;

[0047] Specifically, the particle size of the carbon raw material is 2 μm-40 μm, specifically including: graphite material and / or non-graphite material; wherein the non-graphite material includes: one of soft carbon, hard carbon, porous carbon or mesocarbon microspheres or Several combinations; the graphite material includes: one or more combinations of graphitized mesophase microspheres, natural graphite, modified natural graphite or artificial graphite;

[0048]The above-mentioned compounds that can react with carbon have a particle size of 20nm-2000nm, specifically including: one or more of metal compo...

Embodiment 2

[0065] This embodiment provides a specific method for preparing a high-magnification silicon-based composite material, including:

[0066] (1) uniformly mix metallurgical coke with an average particle size of 20 microns and iron oxide with an average particle size of 1 micron according to a mass ratio of 9:1, heat to 900° C., and keep the temperature for 2 hours;

[0067] (2) heat-treating the obtained material at 3000°C to obtain porous carbon;

[0068] (3) Heating metal silicon powder with a median particle size of 20 microns to 1500° C. under 10 Pa, and depositing it on porous carbon according to a mass ratio of 1:9;

[0069] (4) The obtained material was mixed with petroleum pitch at a mass ratio of 8:2 and then heat-treated at 850°C for 2 hours to obtain a high-magnification silicon-based composite material.

[0070] The prepared high-magnification silicon-based composite material and graphite A are uniformly mixed according to the mass ratio of 1:2 and used as the lithi...

Embodiment 3

[0077] This embodiment provides a specific method for preparing a high-magnification silicon-based composite material, including:

[0078] (1) Evenly mix phenolic resin pyrolytic carbon with an average particle size of 20 microns and copper oxide with an average particle size of 500 nm according to a mass ratio of 9:1, heat to 800° C., and keep warm for 2 hours;

[0079] (2) After stirring the obtained material in 10% dilute nitric acid for 8 hours, rinse repeatedly with pure water to obtain porous carbon;

[0080] (3) Metal silicon powder with a median particle size of 20 microns is heated to 1500° C. under 10 Pa, and deposited on porous carbon according to a mass ratio of 2:8;

[0081] (4) The obtained material was mixed with polyvinyl alcohol at a mass ratio of 8:2, and then heat-treated at 850° C. for 2 hours to obtain a high-magnification silicon-based composite material.

[0082] The obtained high-rate silicon-based composite material and soft carbon material were mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com