Preparation method of positive pole material (spinel type lithium nickel manganese oxide) of high-voltage lithium ion battery

A technology for lithium ion batteries and cathode materials, applied in the field of materials, can solve the problems of side reactions of electrolyte, low crystallinity of products, large particle size, etc., and achieve the effects of increasing hydrothermal temperature, prolonging hydrothermal time, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific embodiment one: this embodiment prepares lithium nickel manganese oxide material according to the following steps:

[0023] Weigh 0.021mol Li(CH 3 COO), 0.01mol Ni(CH 3 COO) 2 and 0.03mol Mn(CH 3 COO) 2 , dissolved in 50ml of deionized water, stirred evenly; then added 10ml of absolute ethanol, stirred evenly; while stirring, slowly added 50ml of 2mol / L ammonium bicarbonate solution dropwise.

[0024] The above mixture was transferred to a 200ml hydrothermal reactor, reacted at 180°C for 5h, then evaporated with stirring at 80°C, and dried to obtain a precursor.

[0025] The above precursor was placed in a muffle furnace, pre-calcined at 400°C for 4 hours, calcined at 800°C for 10 hours, and then cooled at a rate of 0.5°C / min to obtain a lithium nickel manganate material.

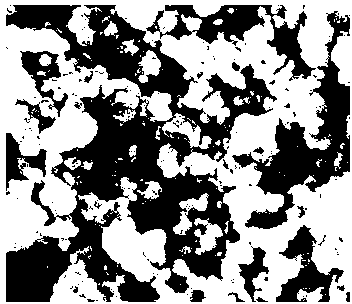

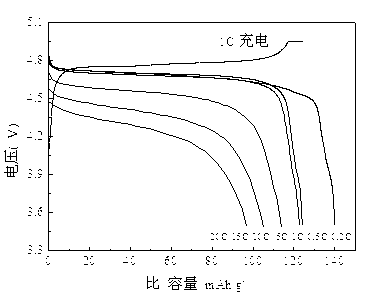

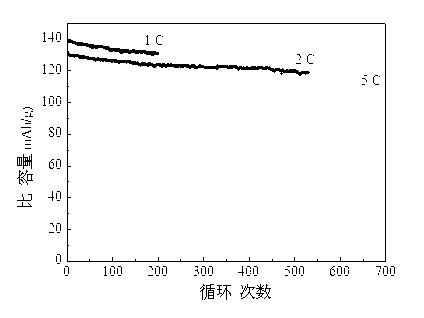

[0026] Such as Figure 1-3 As shown, the particle size of the lithium nickel manganese oxide material prepared in this embodiment is about 1 μm, and the specific capacity can reach 140...

specific Embodiment approach 2

[0027] Specific embodiment two: this embodiment prepares lithium nickel manganese oxide material according to the following steps:

[0028] Weigh 0.021mol Li(CH 3 COO), 0.01mol Ni(CH 3 COO) 2 , 0.03mol Mn(CH 3 COO) 2 , dissolved in 50ml of deionized water, stirred evenly; then added 10ml of absolute ethanol, stirred evenly; while stirring, slowly added 50ml of 2mol / L ammonium bicarbonate solution dropwise.

[0029] The above mixture was transferred to a 200ml hydrothermal reactor, reacted at 160°C for 3h, then evaporated with stirring at 80°C, and dried to obtain a precursor.

[0030] The above precursors were placed in a muffle furnace, pre-calcined at 400°C for 3 hours, calcined at 800°C for 12 hours, and then cooled at 0.5°C / min to obtain a lithium nickel manganese oxide material with a particle size of about 0.5 μm. When discharged at 1C and 5C, the specific capacity can reach 142mAh / g and 120mAh / g, and it has good rate performance and cycle performance.

specific Embodiment approach 3

[0031] Specific embodiment three: this embodiment prepares lithium nickel manganese oxide material according to the following steps:

[0032] Weigh 0.01mol Li(CH 3 COO), 0.005mol Ni(CH 3 COO) 2 , 0.015mol Mn(CH 3 COO) 2 , dissolved in 50ml of deionized water, stirred evenly; added 10ml of absolute ethanol, stirred evenly; while stirring, slowly added 50ml of 1mol / L ammonium bicarbonate solution dropwise.

[0033] The above mixture was transferred to a 200ml hydrothermal reactor, reacted at 180°C for 5h, then evaporated with stirring at 80°C, and dried to obtain a precursor.

[0034] The above precursors were placed in a muffle furnace, pre-calcined at 400°C for 4 hours, calcined at 800°C for 10 hours, and then cooled at 0.5°C / min to obtain a lithium nickel manganese oxide material with a particle size of about 2 μm. When discharged at 1C and 5C, the specific capacity can reach 135mAh / g and 105.5mAh / g, and it has good rate performance and cycle performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com