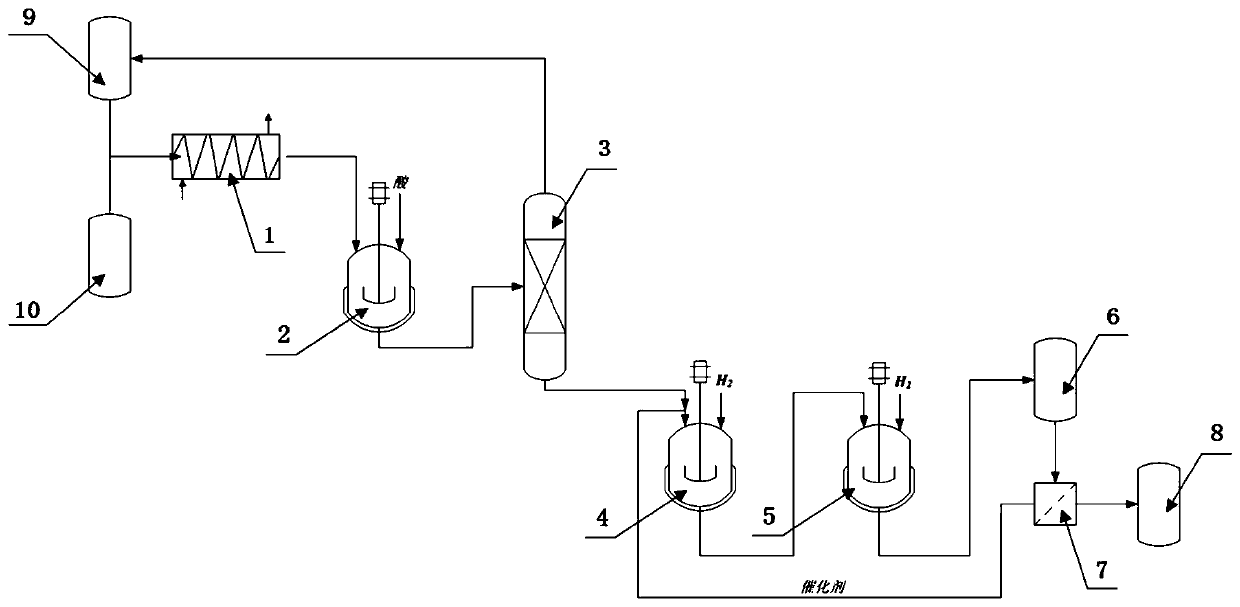

Method and system for preparing 1, 3-butanediol with high selectivity

A high-selectivity, butanediol technology, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, and preparation of organic compounds, etc., can solve problems such as unstable output rate, achieve the effect of reducing side reactions and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, the inner diameter of the coiled tube of the coiled tube reactor 1 is 3.0 mm, the wall thickness is 0.8 mm, and the length is 35.0 m.

[0046] The experimental steps are as described above, wherein:

[0047] S1. Preparation of crude 3-hydroxybutyraldehyde: the inorganic base is 10wt% NaOH aqueous solution, and the mass ratio of acetaldehyde and NaOH entering coil reactor 1 is 25:1. The pH of the reaction system was 13.0, and the residence time of the reaction solution was 7.5 minutes. A cooling medium is passed through the interlayer of the heat exchange chamber, and the reaction temperature is controlled to maintain at 3.0±0.8°C.

[0048] S3. Preparation of 1,3-butanediol by hydrogenation: the mass ratio of the skeleton nickel catalyst to the crude 3-hydroxybutyraldehyde solution in the two hydrogenation reactors is 1:6, the reaction temperature is 70°C, and the reaction pressure is 3.5 MPa, the hydrogenation reaction time is 25min.

[0049] Acco...

Embodiment 2

[0051] In this embodiment, the inner diameter of the coiled tube of the coiled tube reactor 1 is 4.0 mm, the wall thickness is 0.9 mm, and the length is 37.5 m.

[0052] The experimental steps are as described above, wherein:

[0053] S1. Preparation of crude 3-hydroxybutyraldehyde: the inorganic base is 10wt% KOH aqueous solution, and the mass ratio of acetaldehyde and KOH entering coil reactor 1 is 35:1. The pH of the reaction system was 13.0, and the residence time of the reaction solution was 6 minutes. A cooling medium is passed through the interlayer of the heat exchange chamber, and the reaction temperature is controlled to maintain at 2.0±0.8°C.

[0054] S3. Preparation of 1,3-butanediol by hydrogenation: the mass ratio of the skeleton nickel catalyst to the crude 3-hydroxybutyraldehyde solution in the two hydrogenation reactors is 1:8, the reaction temperature is 66°C, and the reaction pressure is 4.5 MPa, the hydrogenation reaction time is 30min.

[0055] Accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com