High-performance concrete construction pretreatment process

A high-performance concrete and pre-treatment technology, applied in grain processing, packaging, etc., can solve problems that affect project quality, unqualified quality, and danger, and achieve the effects of precise proportioning, control of incoming standards, and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

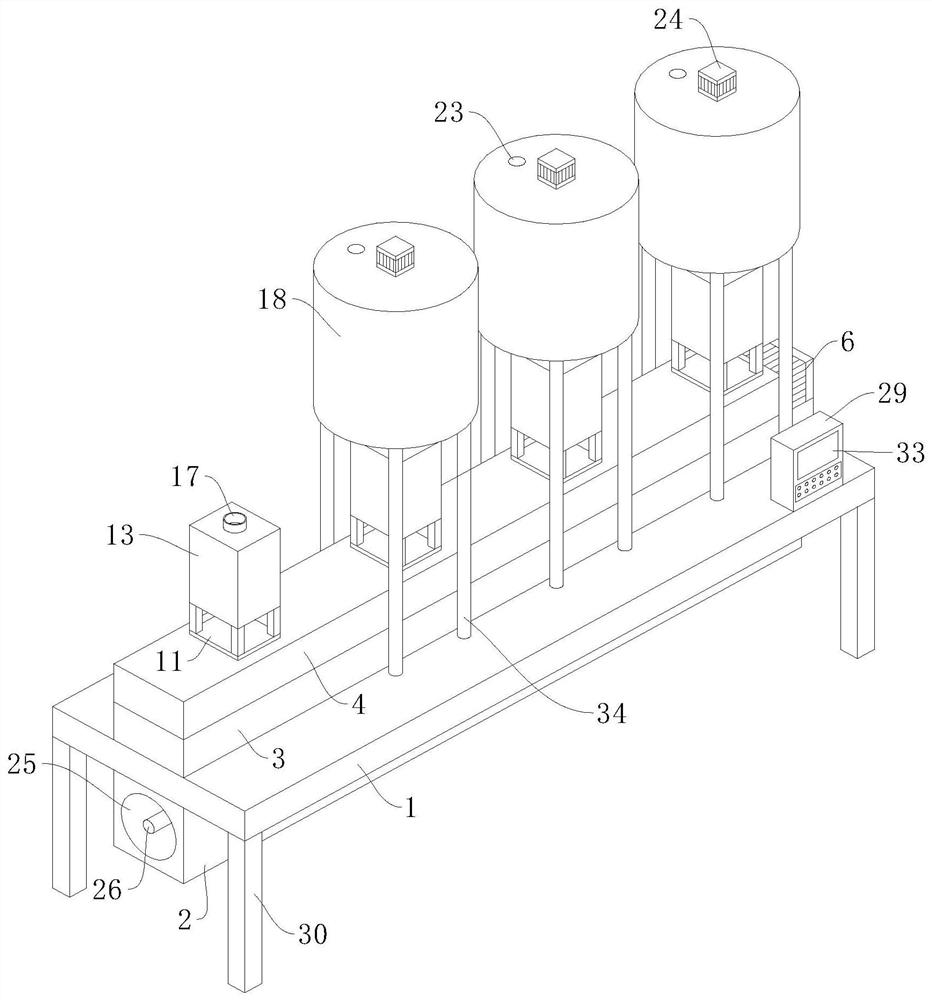

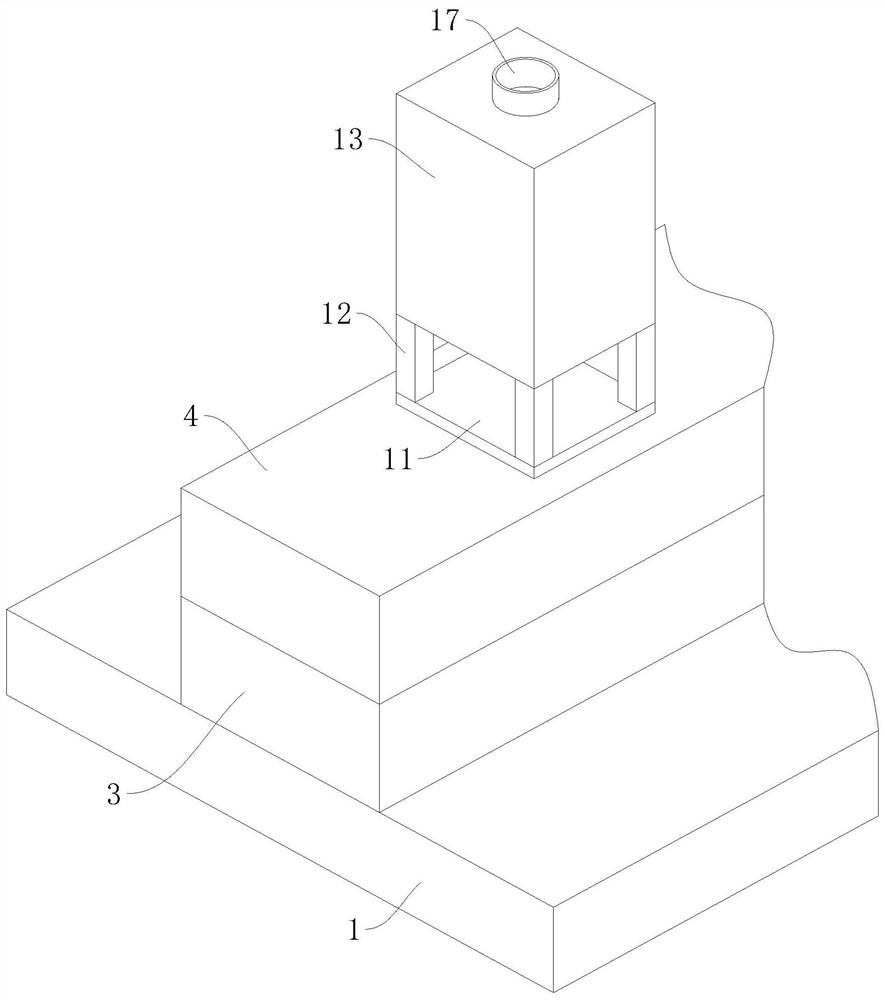

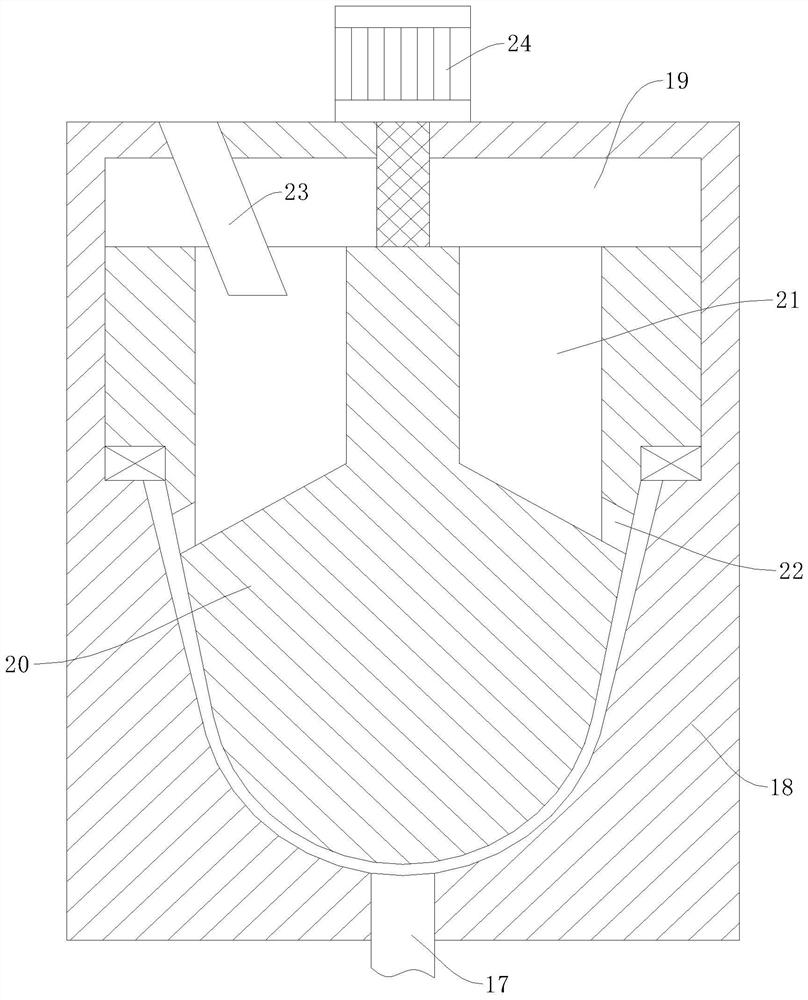

[0042] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 As shown, a high-performance concrete construction pre-treatment process of the present invention includes a placement plate 1 and a transport channel 2, the transport channel 2 is fixed in the middle of the bottom end of the placement plate 1, and the middle part of the top of the placement plate 1 is provided with a transport mechanism. The transport mechanism includes The lower conveying box 3, the upper conveying box 4, the cushion block 5, the conveying motor 6, the rotating shaft 7 and the auger blade 8, and the top of the upper conveying box 4 are equidistantly provided with four metering mechanisms, and the metering mechanism includes a placement groove 9, an annular Pressure sensor 10, load bearing plate 11, connecting column 12, placement box 13, electromagnetic valve 14, circular through hole 15, feeding hose 16 and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com