Preparation of nano alkali metal carbonate and application of nano alkali metal carbonate in preparation of poly(aryl ether ketone)

A technology of alkali metal carbonate and aryl ether ketone, applied in the direction of alkali metal carbonate, alkali metal compound, nanotechnology, etc., can solve the problem of low reactivity of nano-calcium carbonate, and achieve easy operation and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] Embodiment 1 prepares nano potassium carbonate

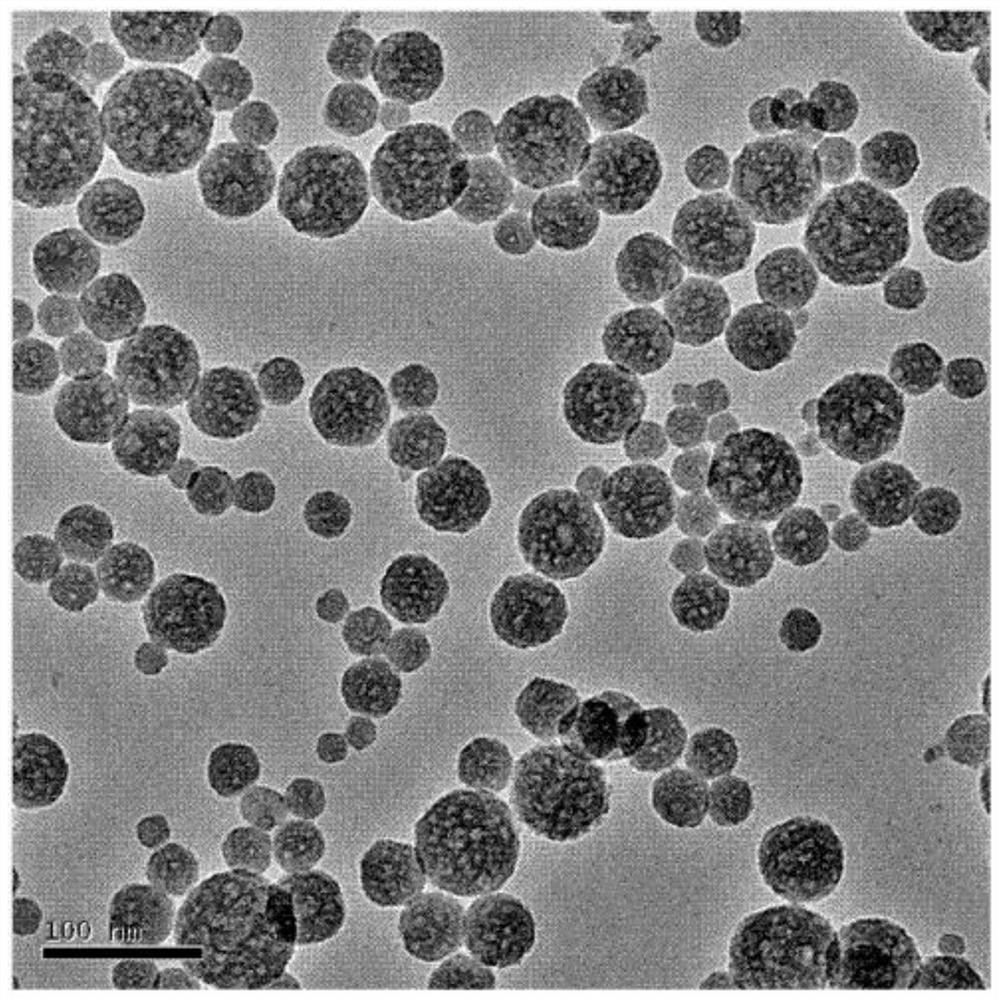

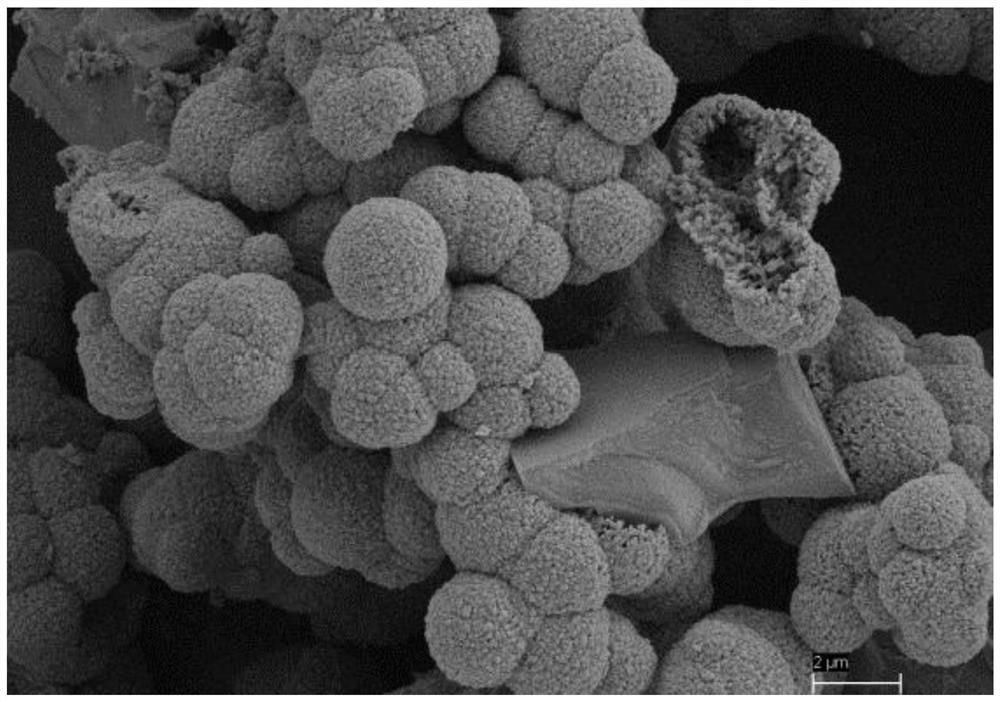

[0098] First, weigh 10g of potassium carbonate, dissolve it in 100ml of distilled water to prepare a potassium carbonate solution, then take 5g of nano-titanium dioxide, and add it to the prepared potassium carbonate solution, stir and mix with a stirrer at high speed, and then add it to the mixture Add 0.2g of polyethylene glycol, stir for 15 minutes, add 0.3g of high-strength foaming agent 4,4'-oxybisbenzenesulfonyl hydrazide to the mixture, stir until a large number of bubbles exist stably, at this time a large amount of Bubble liquid film, potassium carbonate crystallizes on the interface of the liquid film, and then these stable bubbles are spread on the tray and placed in an oven at 56-891 ° C for 12 hours to dry. Finally, the obtained dried product is slightly ground to obtain potassium carbonate particles with nano-scale particle diameters, which are close to spherical in diameter and within the range of 1-2000nm....

Embodiment 2

[0100] Embodiment 2 prepares nano sodium carbonate

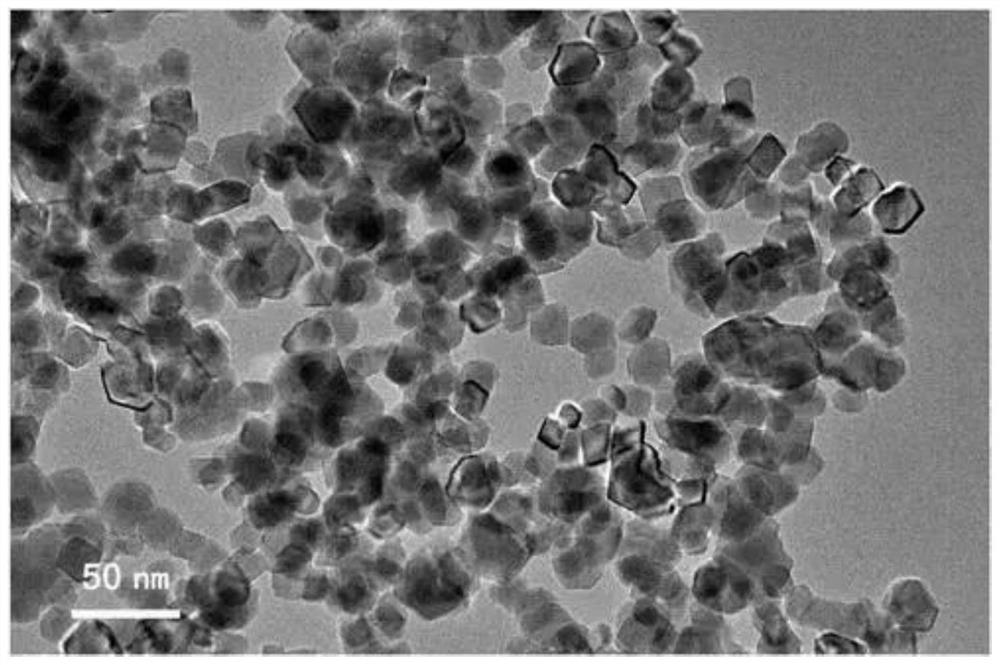

[0101] First weigh 10g of sodium carbonate, dissolve it in 100ml of distilled water to prepare a sodium carbonate solution, then take 2g of nanometer iron sesquioxide Fe 2 o 3 , and add it to the prepared sodium carbonate solution, stir and mix with a stirrer at high speed, then add 0.05g of polyoxyethylene to the mixture, stir for 15 minutes, add 0.08g of high-strength foaming Agent 4,4'-oxobisbenzenesulfonyl hydrazide, stir until a large number of bubbles exist stably, at this time a large number of bubble liquid films are formed, sodium carbonate crystallizes on the liquid film interface, and then spread these stable bubbles on the tray, Dry in an oven at 56-851°C for 12 hours. Finally, the obtained dried product is slightly ground to obtain sodium carbonate particles with a nano-scale particle diameter, which is close to spherical in diameter and within the range of 1-2000nm.

[0102] figure 2 It is the field emissi...

Embodiment 3

[0105] Preparation and purification of embodiment 3 hydroquinone disodium salt (using the nano-sodium carbonate prepared by embodiment 2)

[0106] Preparation: Place a 500ml three-necked bottle in a temperature-regulating electric heating mantle, insert a stirring paddle into the middle port, connect a tee with a thermometer and high-purity nitrogen at one side port, and connect a spherical condenser with the other side port. Weigh 184.18g (2mol) of glycerol and add in the there-necked flask, weigh 110.1g (1mol) of hydroquinone and 127.188g (1.2mol) of nano-sized Na 2 CO 3 Add it into a three-necked flask, feed high-purity nitrogen gas to a flow rate of 200ml / min, heat until the hydroquinone melts, and turn on the stirring paddle to a stirring speed of 85rpm. When the temperature rose to 220° C., the temperature was kept constant for 1 hour, and the reaction was completed, and then cooled to room temperature under the protection of nitrogen at a flow rate of 200 ml / min.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com