Preparation method of lithium-sulphur battery positive pole material with sulfur-graphene composite structure

A graphene composite, lithium-sulfur battery technology, applied in battery electrodes, structural parts, circuits, etc., can solve problems such as damage to the health of operators, limited sulfur load, and time-consuming energy consumption, and achieve the suppression of shuttle and migration channels Short, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

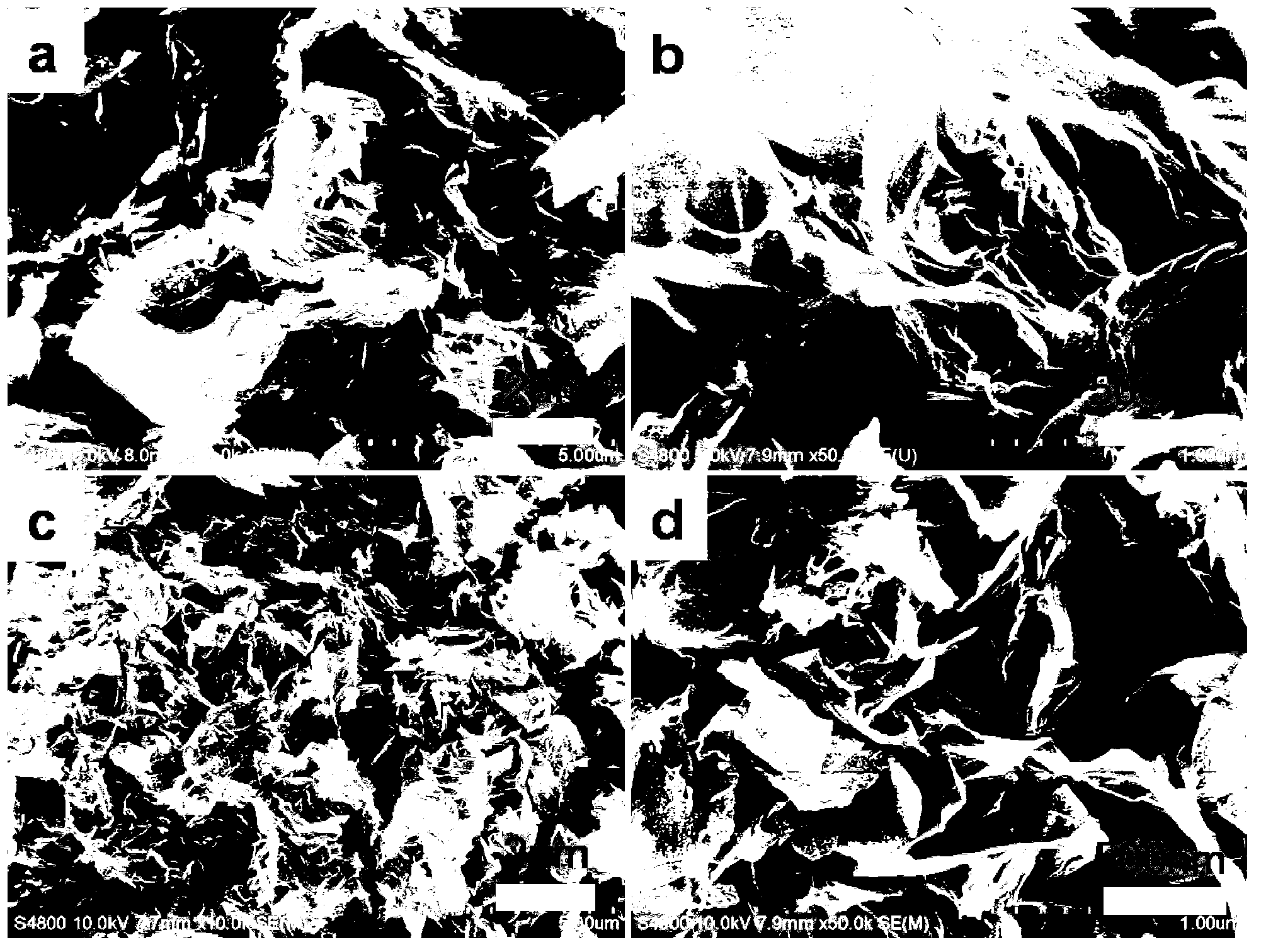

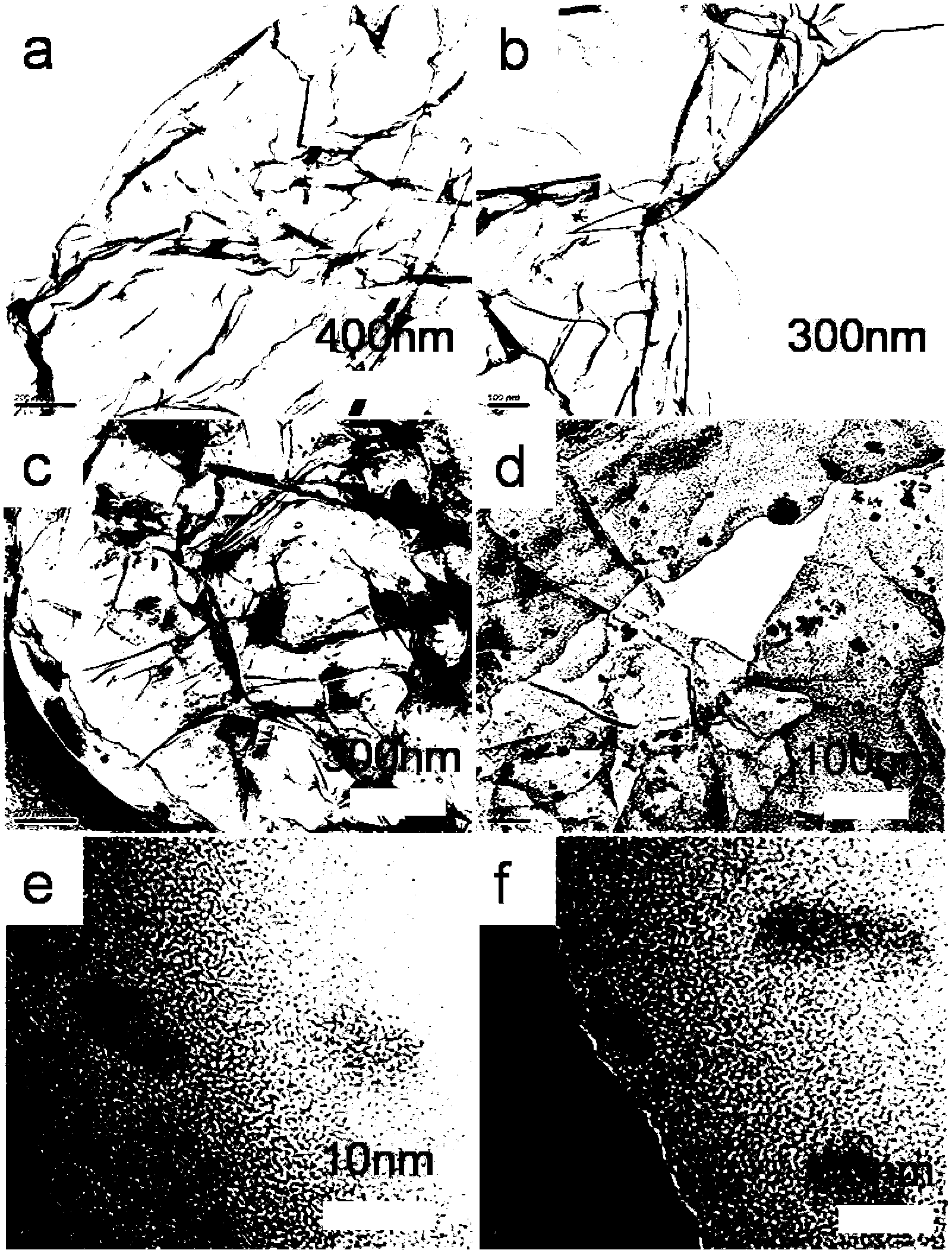

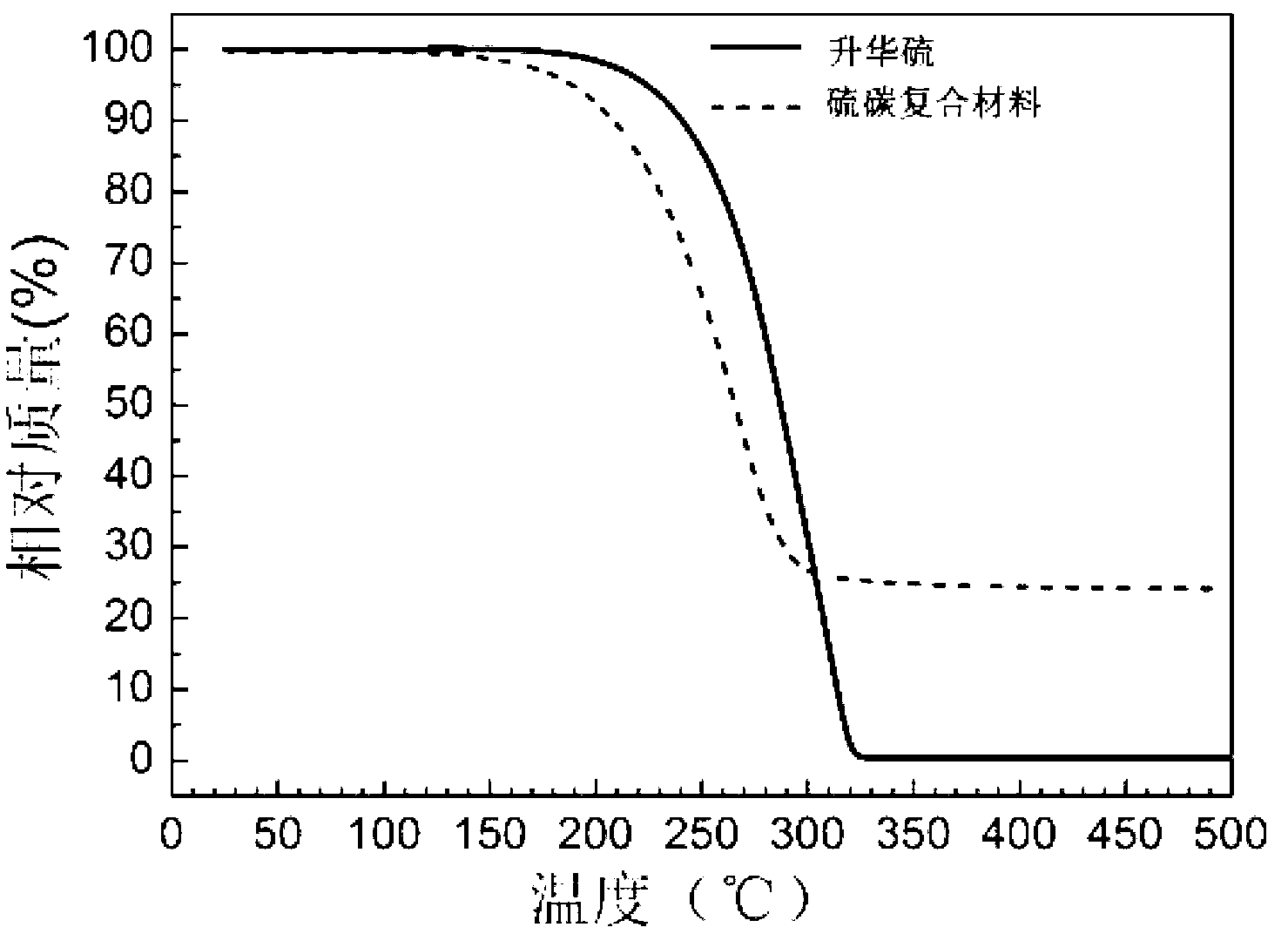

[0028] This embodiment provides a method for preparing a cathode material for a lithium-sulfur battery with a sulfur-graphene composite structure, which is prepared by using graphene, ethylamine and sublimated sulfur as raw materials.

[0029] The specific operation steps are as follows:

[0030] A. Add 0.4 g of sublimed sulfur into 8 mL of ethylamine, and mix uniformly to obtain a first dispersion.

[0031] Take 0.1 g of graphene and add it to 5 mL of acetone, and uniformly mix with ultrasonic waves to obtain a second dispersion;

[0032] B. Under continuous stirring, the first dispersion is added dropwise to the second dispersion at a dropping rate of 0.005 mL / min to obtain a third dispersion;

[0033] C. Slowly add 150 mL of 1 mol / L hydrochloric acid to the third dispersion liquid, and 0.375 g of polyvinylpyrrolidone (PVP) with a molecular weight of 55000 has been dissolved in the hydrochloric acid solution as a surfactant. At this time, nano-sulfur is generated in large ...

Embodiment 2

[0036] This embodiment provides a method for preparing a positive electrode material for a lithium-sulfur battery, which is prepared by using graphene, ethylenediamine, and sublimated sulfur as raw materials.

[0037] The specific operation steps are as follows:

[0038] A. Add 0.2 g of sublimation sulfur into 1 mL of ethylenediamine, and uniformly mix to obtain a first dispersion;

[0039] Take 0.05g of graphene and add it to 50mL of anhydrous ethanol, and uniformly mix with ultrasonic waves to obtain a second dispersion;

[0040] B. Under continuous stirring, the first dispersion is added dropwise to the second dispersion at a dropping rate of 0.05 mL / min to obtain a third dispersion;

[0041] C. Quickly add 150 mL of deionized water to the third dispersion. At this time, nano-sulfur is generated in a large amount in the third dispersion liquid and adsorbed on the surface and pores of graphene, and the composite material is gradually formed;

[0042] D. Continue stirring ...

Embodiment 3

[0056] The present embodiment provides a method for preparing a positive electrode material for a lithium-sulfur battery, which is prepared by using surface-functionalized graphene, methylamine, and sublimated sulfur as raw materials.

[0057] The specific operation steps are as follows:

[0058] A. Add 2 g of sublimed sulfur into 5 mL of methylamine, and mix uniformly to obtain the first dispersion.

[0059] Take 0.5g of functionalized graphene and add it to 25mL of isopropanol, and after uniform mixing with ultrasonic waves, a second dispersion is obtained;

[0060] B. Under continuous stirring, the first dispersion is added dropwise to the second dispersion at a dropping rate of 0.01 mL / min to obtain a third dispersion;

[0061] C. Slowly add 100 mL of 1 mol / L acetic acid to the third dispersion liquid, and 3.64 g of cetyltrimethylammonium bromide (CTAB) has been dissolved in the acetic acid solution. At this time, it can be seen that the nano-sulfur-graphene composite ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com