Dye-sensitized solar cell based on electrospun ultra-fine titanium dioxide fibers and fabrication method thereof

a technology of titanium dioxide and solar cells, applied in titanium dioxide, light-sensitive devices, electrolytic capacitors, etc., can solve the problems of non-liquid electrolyte infiltration, liquid electrolyte leakage, non-liquid electrolyte infiltration, etc., and achieve the effect of improving adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

Example 1

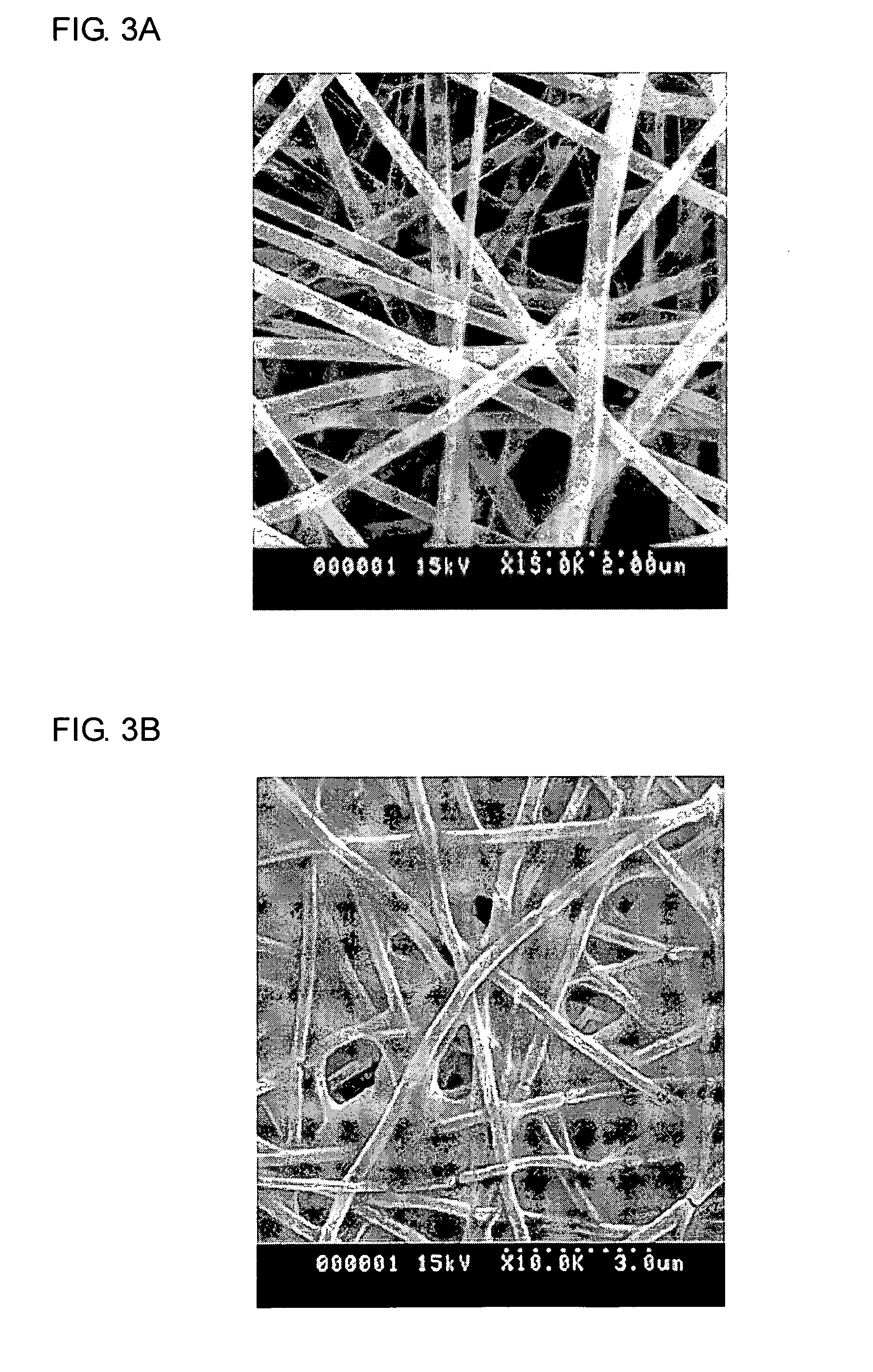

Fabrication of an Electrospun Titanium Dioxide Fiber Layer

[0061] 6 g of titanium isopropoxide was slowly added in a polymer solution in which 30 g of polyvinylacetate (Mw 500,000, a product of Aldrich Co.) was dissolved in a 270 m of acetone and 30 ml of dimethylformamide mixed solvent. As the reaction was initiated by moisture contained in the solvent, the reaction mixture was changed into a suspension. 2.4 g of acetic acid was then slowly added dropwise as a reaction catalyst to the reaction mixture. As the reaction was proceeding, the suspension was changed into a clear solution. The resulting spinning solution should be spun to ultra-fine titanium dioxide fibers within 24 hours once it was prepared, because if it is left for a long time after the acetic acid was added, the solution is changed into a dark brown color due to hydrolysis of the polymer.

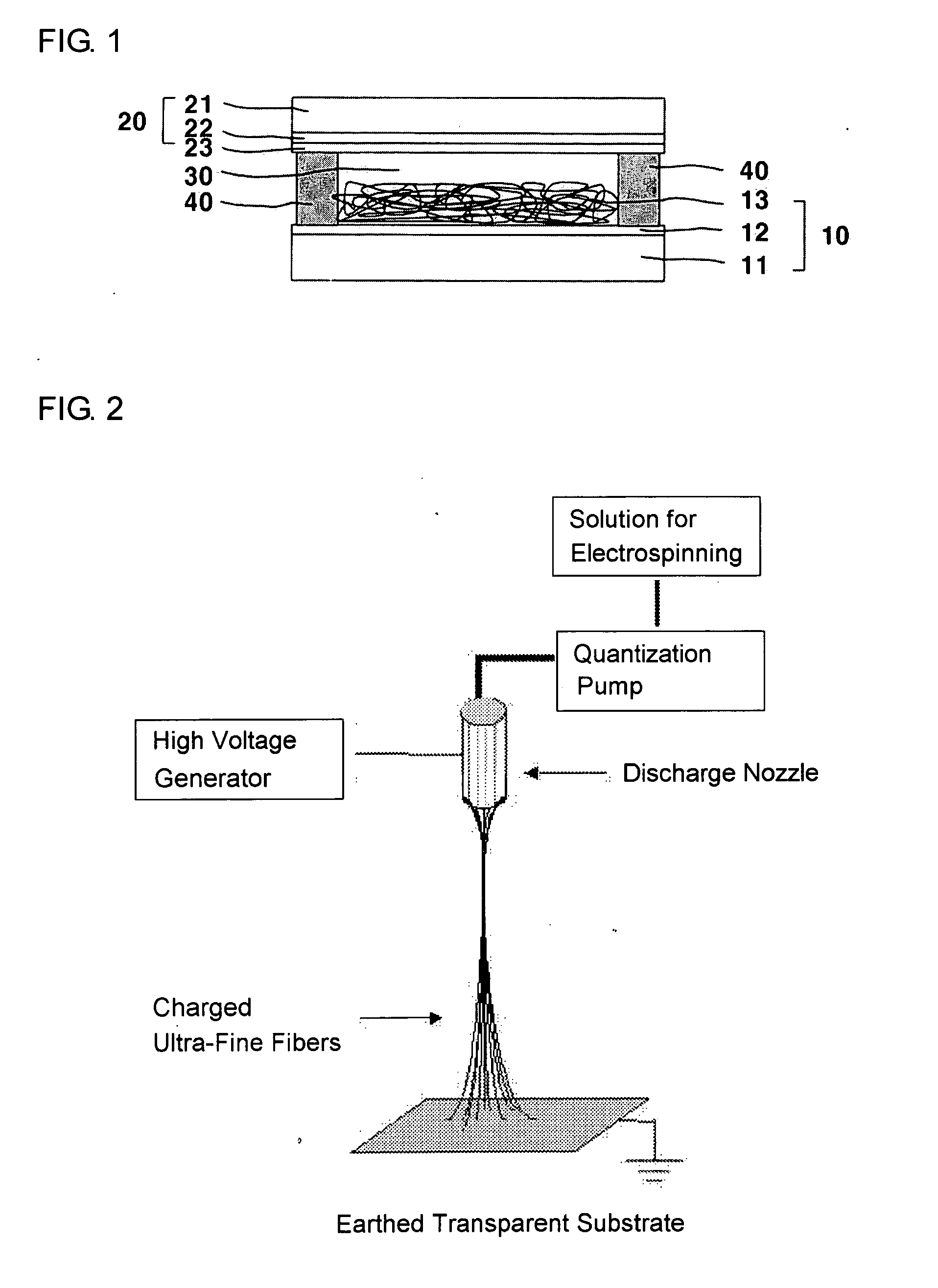

[0062] Electrospinning was performed with the electrospinning apparatus shown in FIG. 2, wherein a FTO-coated transparen...

example 2

Pre-Treatment and Thermal Treatment of the Substrate on Which a Layer of Titanium Dioxide Fibers was Formed Fabricated in Example 1

[0063] The layer of titanium dioxide fibers fabricated in Example 1 includes polymer and titanium dioxide mixed therein. Thus, in order to use the polymer-titanium dioxide composite film-formed substrate as a semiconductor electrode of a dye-sensitized solar cell, the substrate should be thermally treated at a high temperature to remove polyvinylacetate, a polymer binder, and the spun ultra-fine titanium dioxide fibers should be converted into a crystal form. However, if the substrate fabricated in Example 1 is thermally treated at a high temperature without pre-treatment, the titanium dioxide film would not be attached on the FTO-coated substrate but be separated therefrom, and thus, it cannot be used as a semiconductor electrode for a dye-sensitized solar cell.

[0064] Thus, before the thermal treatment, the substrate, on which the polymer-titanium dio...

example 3

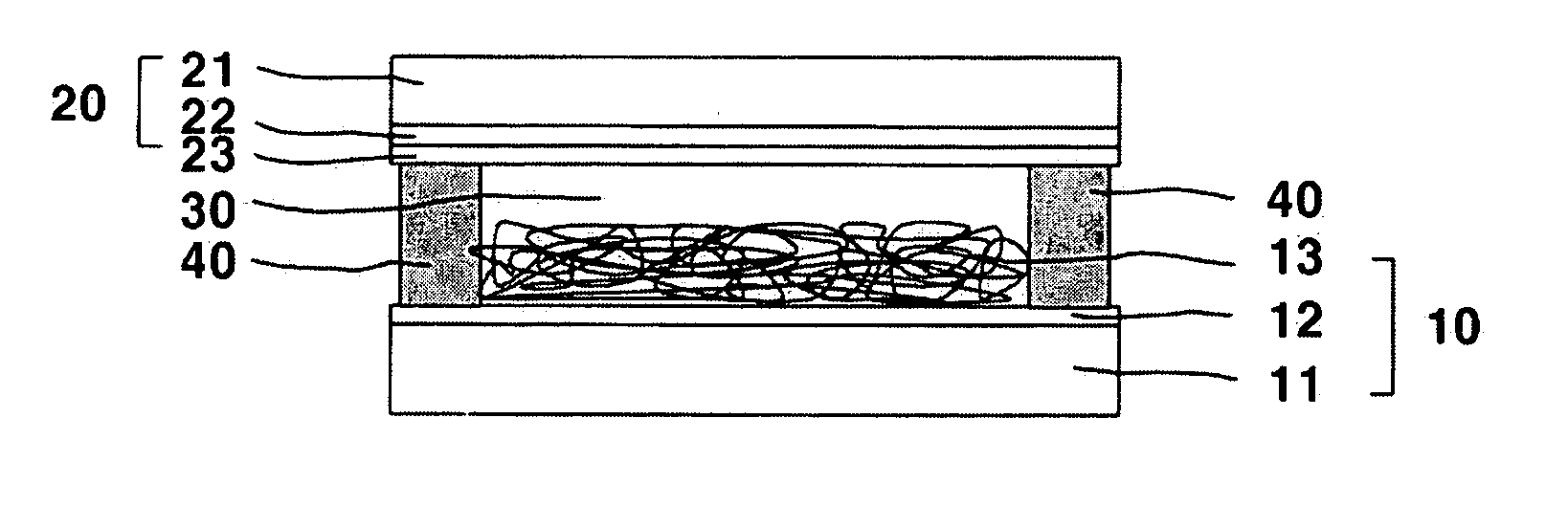

Fabrication of a Dye-Sensitized Solar Cell Using the Titanium Dioxide Fiber Layer Fabricated in Example 2

[0072] Dye molecules were adsorbed onto the ultra-fine titanium dioxide fibers in the substrate fabricated in Example 2. Specifically, the transparent conductive glass substrate fabricated in Example 2 was impregnated in 3×10−4M solution of RuL2(NCS)2 (L=2,2′-bipyridyl-4,4′-dicarboxyl acid) (Ruthenium 535, available from Solaronix,), a ruthenium-based dye, in ethanol for 12 hours, so as to adsorb the dye molecules therein. The resulting substrate was washed with ethanol several times and then dried, thereby to give a semiconductor electrode. Separately, a platinum layer was coated onto a FTO-coated transparent conductive glass substrate to obtain a counter electrode.

[0073] Next, a spacer having a thickness of about 20 μm was located between the semiconductor electrode and the counter electrode fabricated as described above, and a certain pressure was applied thereto at 120° C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com