Gas shielded welding method of bridge steel with tensile strength Rm greater than or equal to 810 MPa

A tensile strength and protection welding technology, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve the problem of no preheating, and achieve improved root toughness, excellent low temperature toughness, and improved crack resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Gas-shielded welding is carried out by using equal-thickness bridge steel plate with base material test plate size of 600mm×400mm×40mm;

[0036] 1) Mechanical properties of the base material: The mechanical properties are characterized by: yield strength R eL : 699MPa, tensile strength R m : 842MPa, Elongation A: 17%, -40℃KV 2 The impact energy is 225J; the thickness is 40mm equal thickness bridge steel;

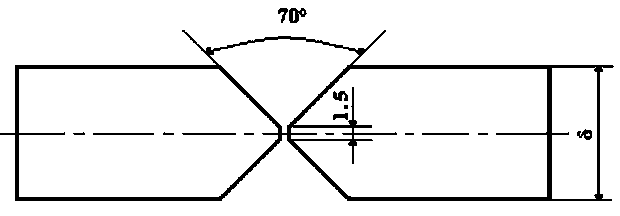

[0037] 2) The groove adopts double-sided V-shaped symmetrical groove, the groove angle is 70°, and the blunt edge is 1.5mm;

[0038] 3) Two matching welding wires: the mechanical properties of the base gas shielded welding wire deposited metal are R eL =492MPa,R m =598MPa, A=27%, Z=65%, impact energy -40℃KV 2 =158J, the diameter of the welding wire is Ф1.2mm; the mechanical properties of the gas shielded welding wire for filling and covering are R eL =791MPa, R m =883MPa, A=17%, Z=64%, impact energy -40℃KV 2 =106J, the wire diameter is Ф1.2mm;

[0039] 4) Wel...

Embodiment 2

[0044] Gas-shielded welding is carried out by using equal-thickness bridge steel plate with base material test plate size of 600mm×400mm×40mm;

[0045] 1) Mechanical properties of the base material: The mechanical properties are characterized by: yield strength R eL : 699MPa, tensile strength R m : 842MPa, Elongation A: 17%, -40℃KV 2 The impact energy is 225J; the thickness is 40mm equal thickness bridge steel;

[0046] 2) The groove adopts double-sided V-shaped symmetrical groove, the groove angle is 70°, and the blunt edge is 1.5mm;

[0047] 3) Two matching welding wires: the mechanical properties of the base gas shielded welding wire deposited metal are R eL =492MPa,R m =598MPa, A=27%, Z=65%, impact energy -40℃KV 2 =158J, the diameter of the welding wire is Ф1.2mm; the mechanical properties of the gas shielded welding wire for filling and covering are R eL =791MPa, R m =883MPa, A=17%, Z=64%, impact energy -40℃KV 2 =106J, the wire diameter is Ф1.2mm;

[0048] 4) Wel...

Embodiment 3

[0053] Gas-shielded welding is carried out by using equal-thickness bridge steel plate with base material test plate size of 600mm×400mm×40mm;

[0054] 1) Mechanical properties of the base material: The mechanical properties are characterized by: yield strength R eL : 704MPa, tensile strength R m : 838MPa, Elongation A: 16%, -40℃KV 2 The impact energy is 230J; the thickness is 40mm equal thickness bridge steel;

[0055] 2) The groove adopts double-sided V-shaped symmetrical groove, the groove angle is 70°, and the blunt edge is 1.5mm;

[0056] 3) Two matching welding wires: the mechanical properties of the base gas shielded welding wire deposited metal are R eL =492MPa,R m =598MPa, A=27%, Z=65%, impact energy -40℃KV 2 =158J, the diameter of the welding wire is Ф1.2mm; the mechanical properties of the gas shielded welding wire for filling and covering are R eL =791MPa, R m =883MPa, A=17%, Z=64%, impact energy -40℃KV 2 =106J, the wire diameter is Ф1.2mm;

[0057] 4) Wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com