Concrete-filled steel pipe column internally provided with high-strength angle steel and construction method thereof

A steel tube concrete column and concrete technology, which is applied in the field of concrete columns, can solve the problems that the high yield strength of high-strength steel cannot be fully utilized, and great safety concerns, etc., to achieve the effects of hindering heat transfer rate, improving fire resistance, and improving fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

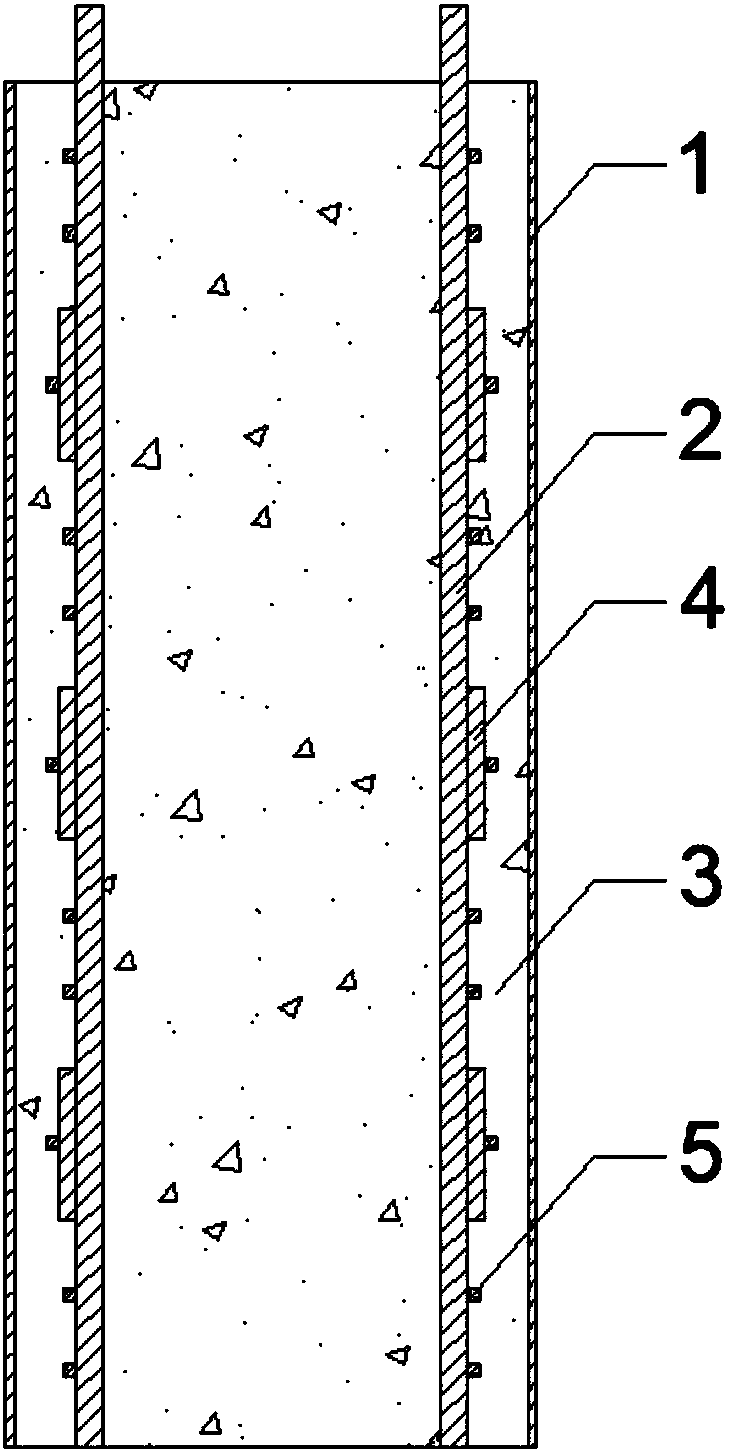

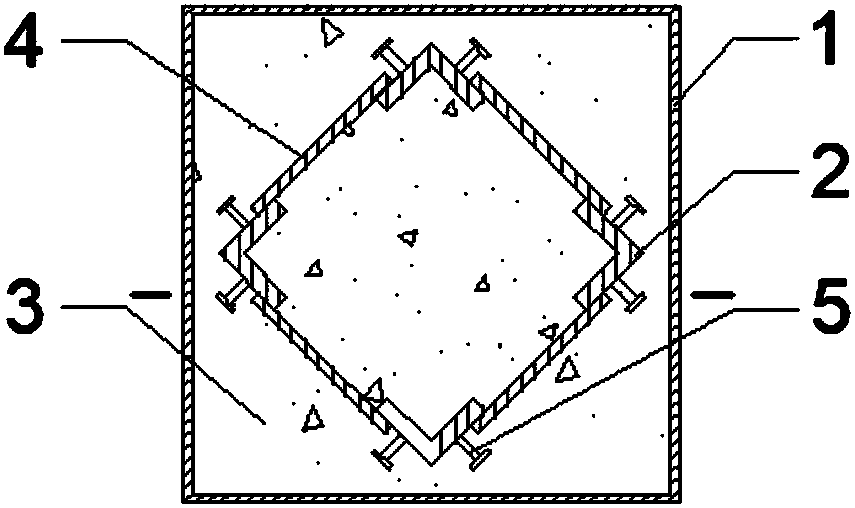

[0037] see Figure 1a , Figure 1b , a steel pipe concrete column with built-in high-strength angle steel, including steel pipe 1, high-strength angle steel 2, concrete 3, connector 4, and stud 5, the steel grade of the steel pipe 1 is Q345, the measured yield strength is 401.9MPa, and its length is 3000mm , the cross section of the steel pipe 1 is square, the side length is 350 mm, and the wall thickness is 6 mm. The high-strength angle steel 2 is an equilateral angle steel, the steel grade is Q690, the measured yield strength is 799.2MPa, the side length is 55mm, the thickness is 12mm, and the length is 3150mm. The number is four, and the adjacent clear distance is greater than 100mm. The penetrating ones are evenly arranged inside the steel pipe 1 and are separated from the inner wall of the steel pipe 1 by 20mm. The vertices of each high-strength angle steel 2 point to the middle of the corresponding side of the polygon, and the openings all face the center of the concret...

Embodiment 2

[0046] In this embodiment, except for the following features, other features are the same as in Embodiment 1:

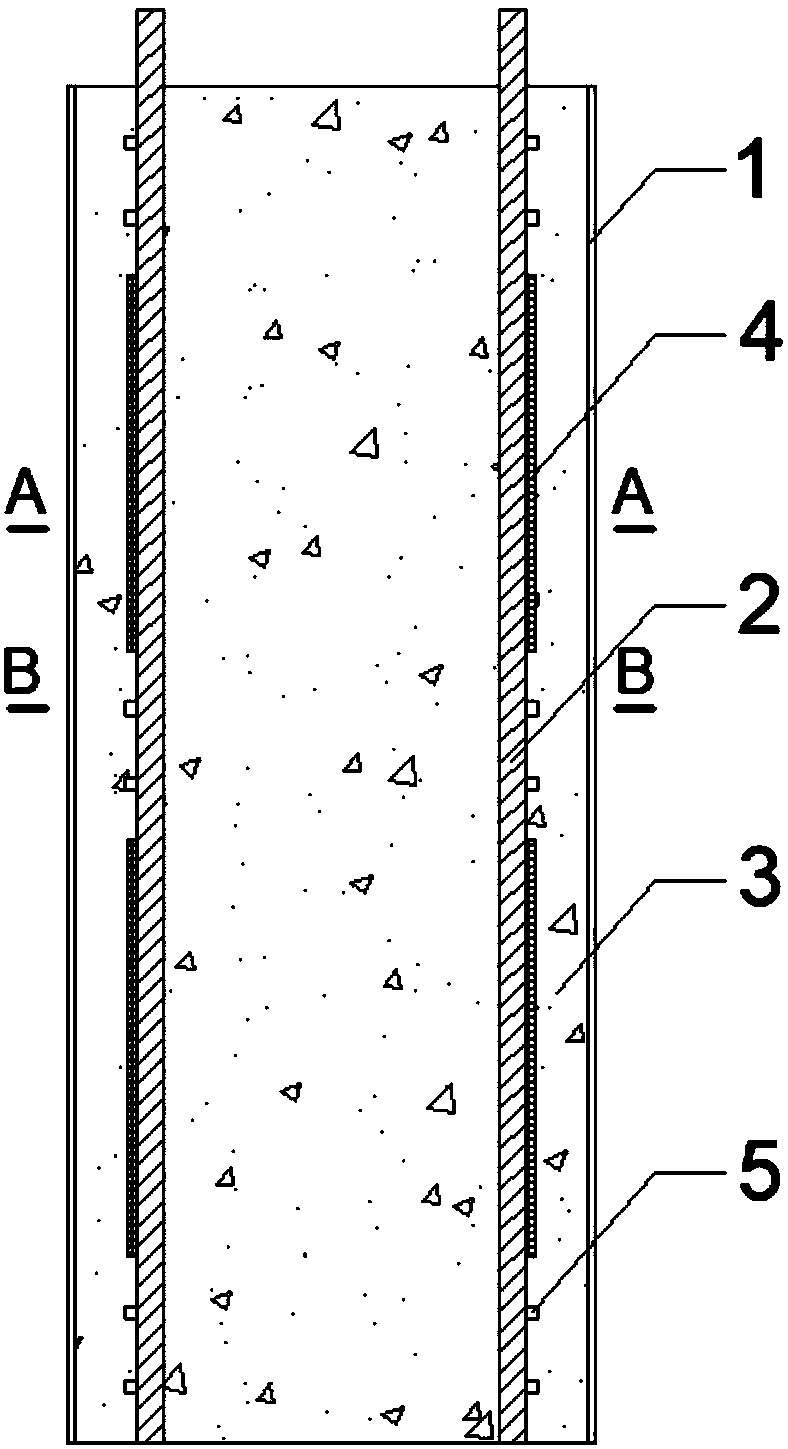

[0047] see Figure 2a , Figure 2b , Figure 2c , the connector 4 is a fiber-reinforced polymer cloth with a thickness of 1mm and a height of 500mm, which is wound around the high-strength angle steel 2 for 2 turns;

[0048] In addition, in the construction method of this embodiment, the first step is: place a steel base plate at the construction position, and weld four high-strength angle steels 2 upright on the steel base plate in sequence; wind fiber reinforced polymer cloth around each high-strength angle steel The outer surface at heights of 1000mm and 2000mm of 2; the studs 5 are welded to the outer surface of the high-strength angle steel 2 at intervals. The third step is: pour concrete into the steel pipe 1 until it is 100 mm away from the upper surface of the steel pipe 1 and stop pouring; then the high-strength angle steels 2 on the upper layer of the bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com