Lightweight steel-coarse aggregate reactive powder concrete composite beam structure

A technology of active powder and coarse aggregate, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems affecting the safety and durability of bridge structures, increase the size of the cable tower and the specifications of the stay cables, and reduce the tensile strength and shrinkage. Creep and other problems, to achieve the effect of widening the applicable span, superior seismic performance, and improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

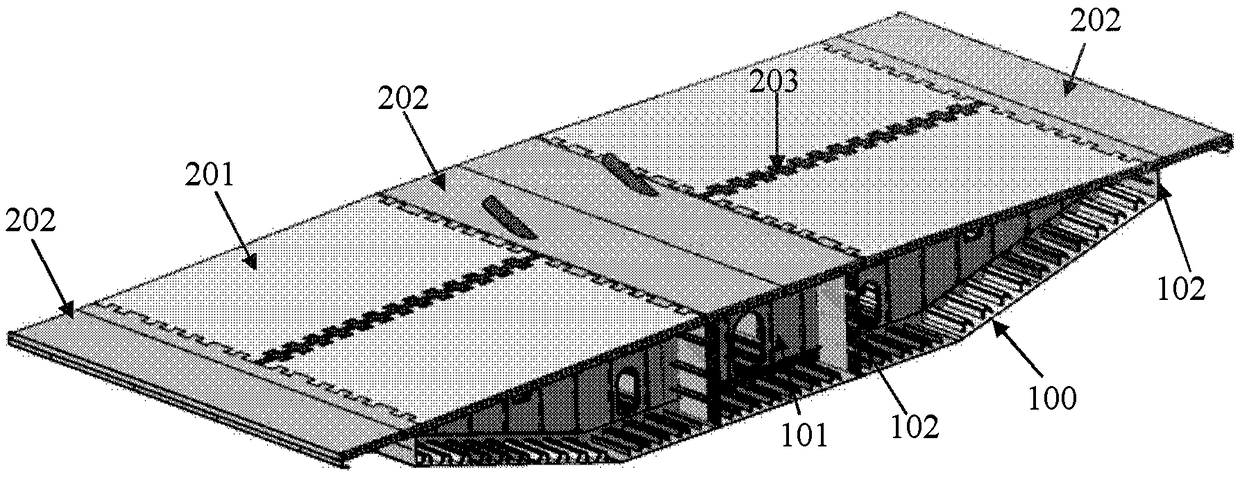

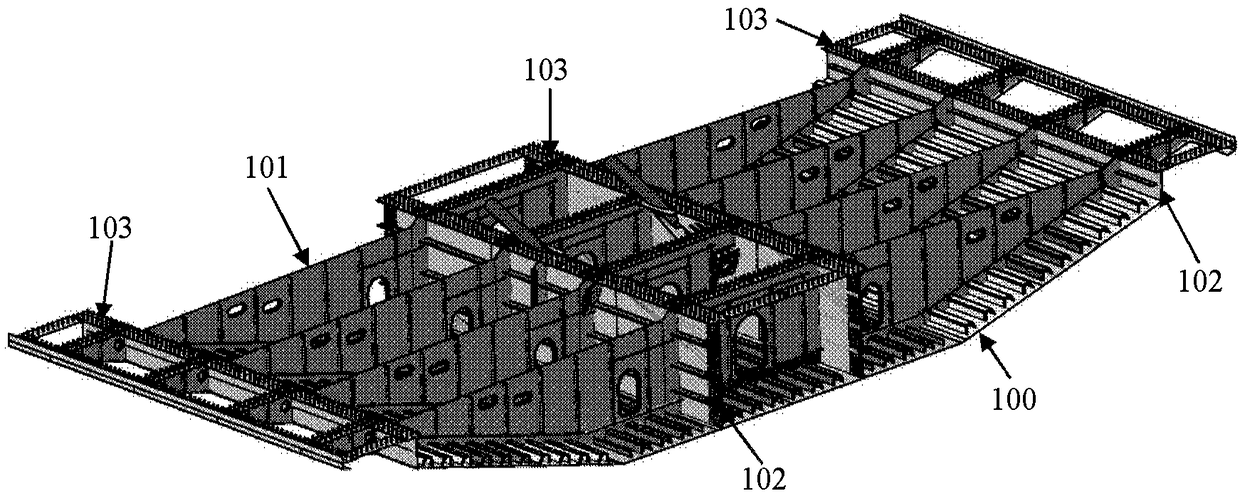

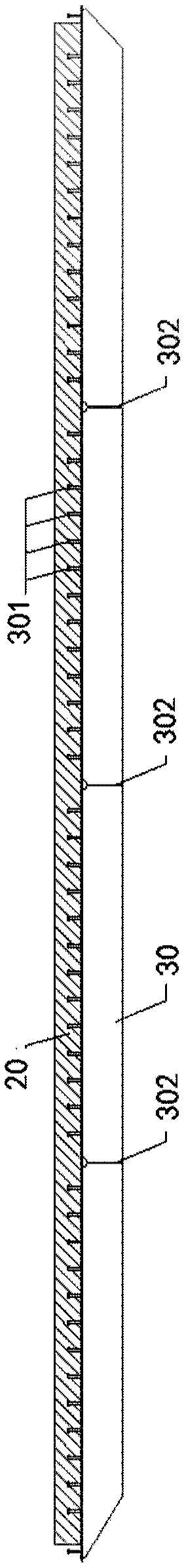

[0040] The present disclosure provides a lightweight steel-coarse aggregate reactive powder concrete composite beam structure, which aims to improve the mechanical performance of the steel-concrete composite beam, increase its applicable span and applicable scope, and improve the construction speed and process quality of bridge engineering. While reducing the mechanical properties of the concrete bridge deck, it overcomes the self-weight of the traditional steel-concrete composite beam and the easy cracking of the bridge deck.

[0041] In order to make the objectives, technical solutions, and advantages of the present disclosure clearer, the following further describes the present disclosure in detail with reference to specific embodiments and drawings.

[0042] Certain embodiments of the present disclosure will be described more fully in the following with reference to the accompanying drawings, and some but not all of the embodiments will be shown. In fact, various embodiments of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com