Concrete internal curing agent as well as preparation method and using method thereof

An internal and curing agent technology for concrete, which is applied in the field of concrete internal curing agent, can solve the problems of wasting water resources, manpower and material resources, large changes in slump over time, unable to meet construction requirements, etc., so as to promote sustainable development of resources and reduce later stages Maintenance cost and effect of saving maintenance water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

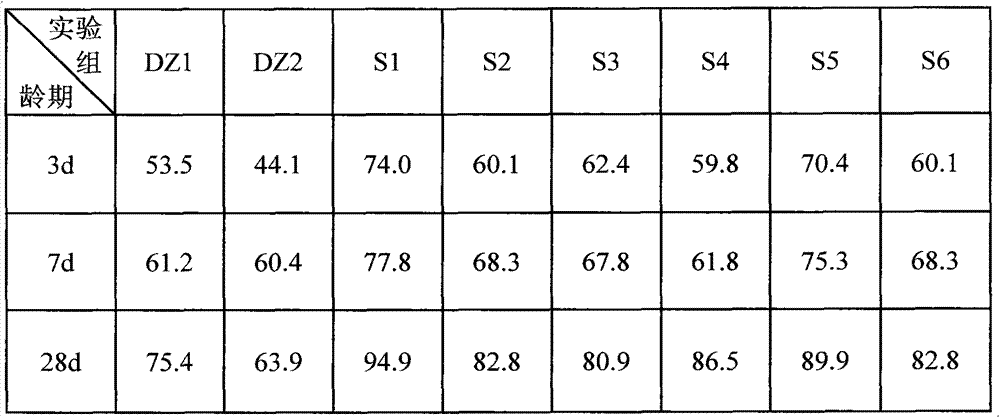

Examples

Embodiment 1

[0029] Formula: 47.6% deionized water, 22.4% acrylic acid, 5% sodium hydroxide, 17.9% sodium persulfate, 0.3% N'N-methylenebisacrylamide, 6.8% kaolin.

[0030] Preparation:

[0031] First dissolve sodium hydroxide in deionized water, then mix it with acrylic acid evenly, and control the temperature of the mixture below 50°C; then add sodium persulfate, N'N-methylenebisacrylamide and kaolin in sequence, and stir Uniform, microwave treatment in a microwave oven with a microwave power of 270W for 2 minutes, you can get the expansion of the concrete internal curing agent; soak the obtained expansion in alcohol that has not passed the surface of the expansion for 30 minutes, and then put it into an oven with a constant temperature of 80 degrees to Dry at 100°C for 8 hours to obtain a bulky concrete internal curing agent; crush the bulky concrete internal curing agent with a pulverizer, and then sieve it with an 80-mesh sieve to obtain a concrete internal curing agent with a mesh nu...

Embodiment 2

[0033] Formula: 47.8% deionized water, 22.1% acrylic acid, 5.5% sodium hydroxide, 17.7% sodium persulfate, 0.3% N'N-methylenebisacrylamide, 6.6% kaolin.

[0034] The preparation method was the same as in Example 1, and an 80-mesh concrete internal curing agent was prepared.

Embodiment 3

[0036] Formula: 48% deionized water, 21.7% acrylic acid, 6.1% sodium hydroxide, 17.4% sodium persulfate, 0.3% N'N-methylenebisacrylamide, 6.5% kaolin.

[0037] The preparation method was the same as in Example 1, and an 80-mesh concrete internal curing agent was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com