Method for testing property of low-carbon asphalt and low-carbon asphalt mixtures

A technology of asphalt mixture and measurement method, which is applied in the direction of material inspection product, investigation stage/state change, etc., can solve the problems of inability to measure low-carbon asphalt mixing, compaction temperature, low-carbon asphalt aging environment and production safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

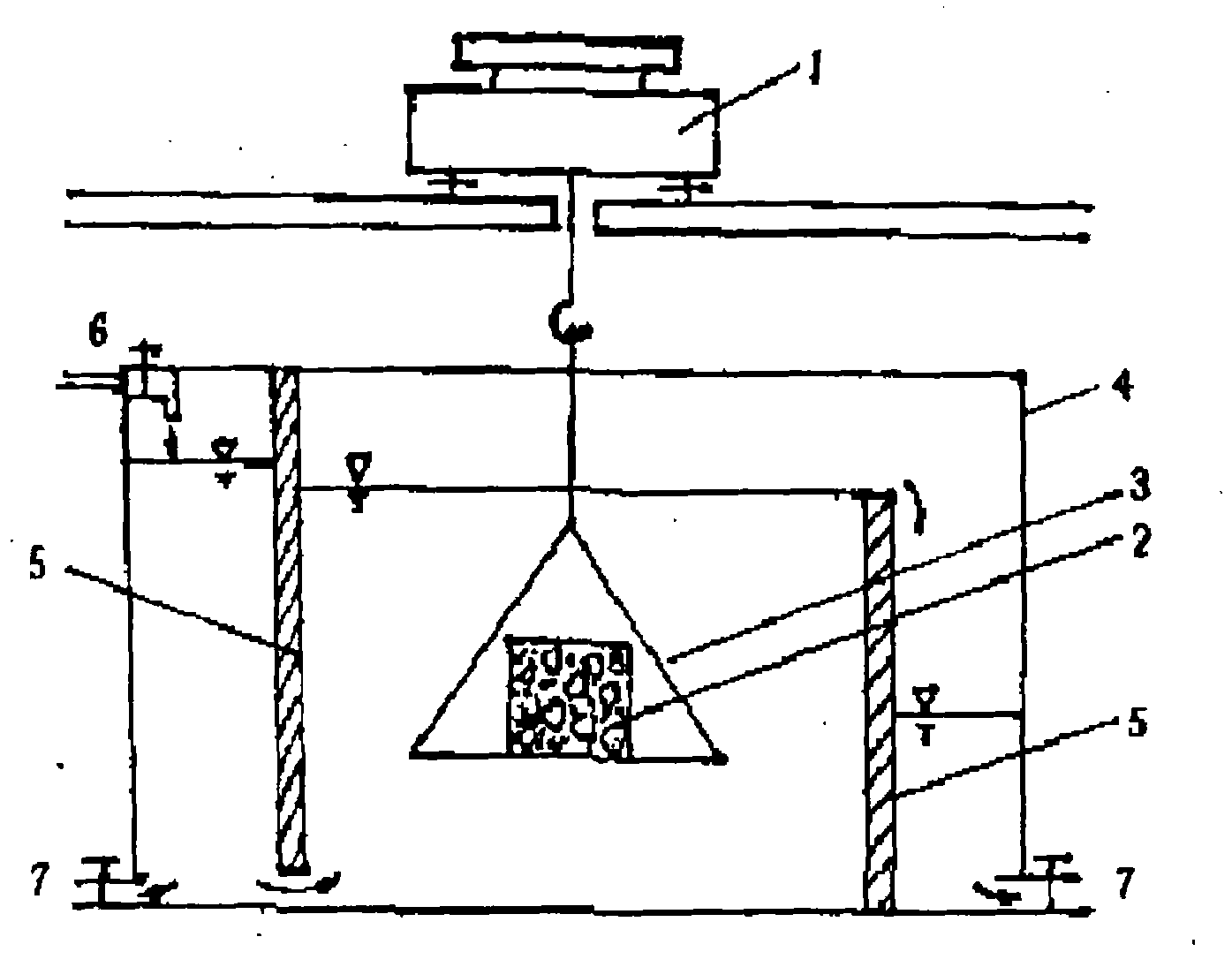

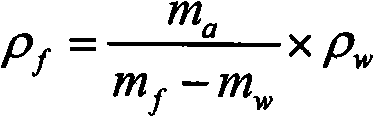

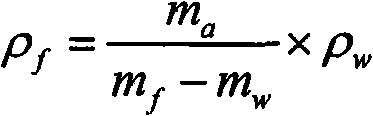

[0032] 1. Determination of mixing temperature of low carbon asphalt

[0033] The temperature of mixing and compaction is an important factor affecting the ratio design and quality control of asphalt mixture, which directly affects the design results of asphalt mixture ratio, asphalt pavement construction quality and road performance. "Technical Specifications for Construction of Highway Asphalt Pavement" (JTGF40-2004) The mixing and compacting temperature of ordinary asphalt mixture should be determined by the method of viscosity-temperature curve. The compaction temperature is often too high, and too high mixing and compaction temperature will cause problems such as aging of low-carbon asphalt, environment and production safety.

[0034] The present invention is further illustrated below by examples. A traditional AC-13 mixture with compact structure is selected as a sample. The cementing material is 70# matrix asphalt, and the low carbon agent is A and B.

[0035] 1) Low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com