Clay inhibitor combined with polycarboxylic water reducer for use

A technology of clay inhibitor and water reducing agent, which is applied in the field of preparation of clay inhibitor, can solve the problems of rising air content, adverse effect on later strength, prolonging of concrete setting time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

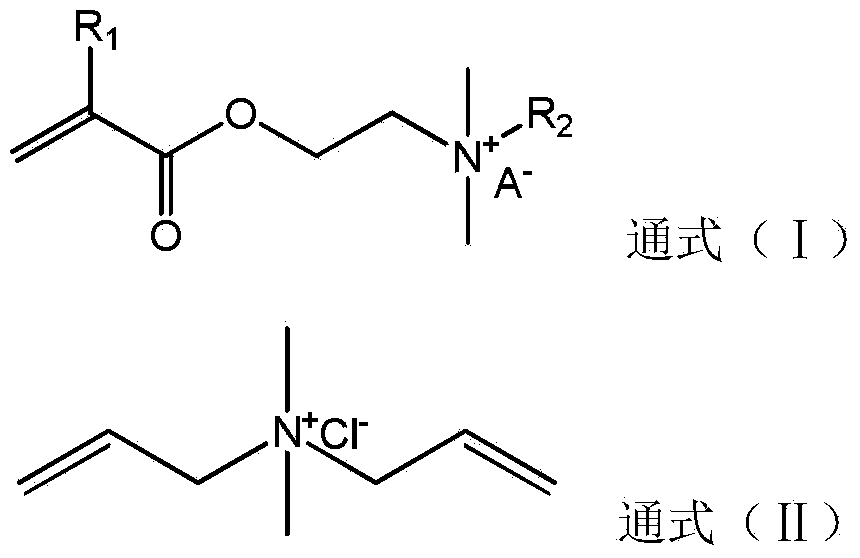

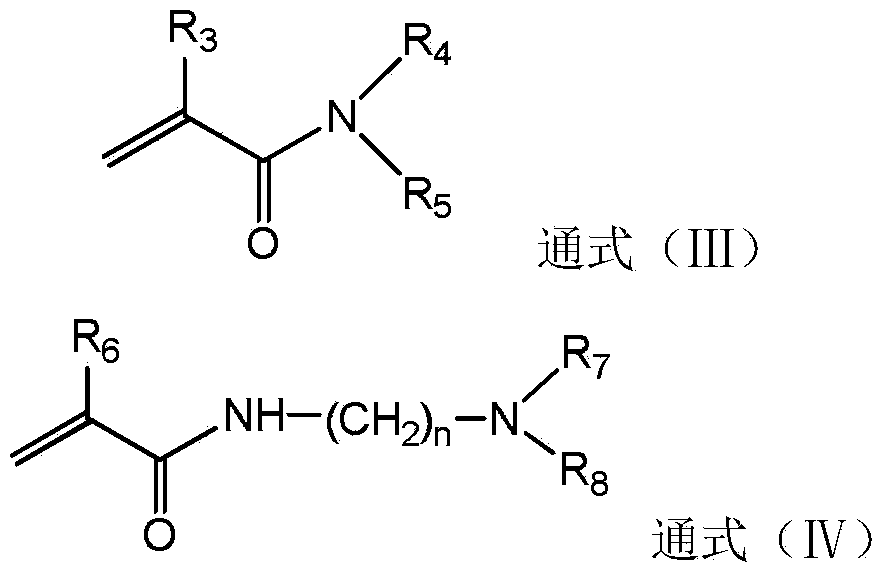

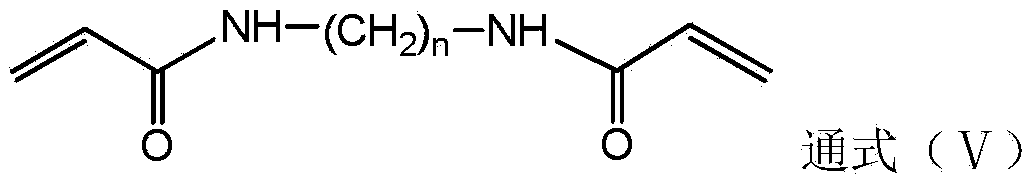

Method used

Image

Examples

Embodiment 1

[0037] In a 1L glass round-bottomed flask equipped with a thermometer, a stirrer, a dropping funnel and a nitrogen conduit, add 400 g of distilled water, stir to raise the temperature, and purge the round-bottomed flask with nitrogen to get rid of the oxygen in the system. Under the protection of nitrogen, the temperature was raised to 90°C, and then 45.8g of monomer a-1, 12.3g of monomer a-2, 27.2g of monomer b-1, 9.3g of monomer c-1, 0.48g of 3-mercaptopropionic acid Mix and stir with 200g of water to form a homogeneous monomer aqueous solution, and drop it into a round bottom flask at a constant speed for 5 hours. At the same time, an aqueous initiator solution prepared by 205 g of distilled water and 1.8 g of potassium persulfate was added dropwise at a constant speed for 5.5 hours. After adding all the solutions dropwise, keep the constant temperature for 6 hours, then cool down to about 40°C and discharge to obtain the clay modifier PA-1 with a solid content of 10.5%.

Embodiment 2

[0039] In a 1L glass round-bottomed flask equipped with a thermometer, a stirrer, a dropping funnel and a nitrogen conduit, add 300 g of distilled water, stir to raise the temperature, and purge the round-bottomed flask with nitrogen to remove the oxygen in the system. Under the protection of nitrogen, the temperature was raised to 80°C, and then 165.4g of monomer a-2, 17.6g of monomer b-2, 2.4g of monomer c-2, 3.5g of thioglycolic acid and 250g of water were mixed and stirred to form a uniform single The aqueous solution was added dropwise to the round bottom flask at a constant speed for 4 hours. At the same time, an aqueous initiator solution prepared by 164 g of distilled water and 1.2 g of azobisisobutylamidine hydrochloride was added dropwise at a constant speed for 4.5 hours. After adding all the solutions dropwise, continue to keep constant temperature for 5 hours, then cool down to about 40°C and discharge to obtain clay modifier PA-2 with a solid content of 20.6%.

Embodiment 3

[0041] In a 1L glass round-bottomed flask equipped with a thermometer, a stirrer, a dropping funnel and a nitrogen conduit, add 300 g of distilled water, stir to raise the temperature, and purge the round-bottomed flask with nitrogen to remove the oxygen in the system. Under nitrogen protection, the temperature was raised to 50°C, and then 113.6g of monomer a-3, 7.5g of monomer b-3, 21.1g of monomer c-1, 1.7g of 2-mercaptopropionic acid, 0.35g of sodium bisulfite and 250g of water was mixed and stirred to form a homogeneous monomer aqueous solution, which was added dropwise into a round bottom flask at a constant speed for 2 hours. At the same time, an aqueous initiator solution prepared by 207 g of distilled water and 1.73 g of potassium persulfate was added dropwise at a constant speed for 2.5 hours. After the dropwise addition of the whole solution, continue to keep the constant temperature for 6 hours, then cool down to about 40°C and discharge the material to obtain the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com