High-performance concrete and preparation method thereof

A technology of high-performance concrete and recycled aggregate, which is applied in the field of concrete, can solve the problems of large porosity of recycled aggregate, workability of recycled concrete, impermeability, decreased strength performance, and increased performance degradation. The effect of excellent permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

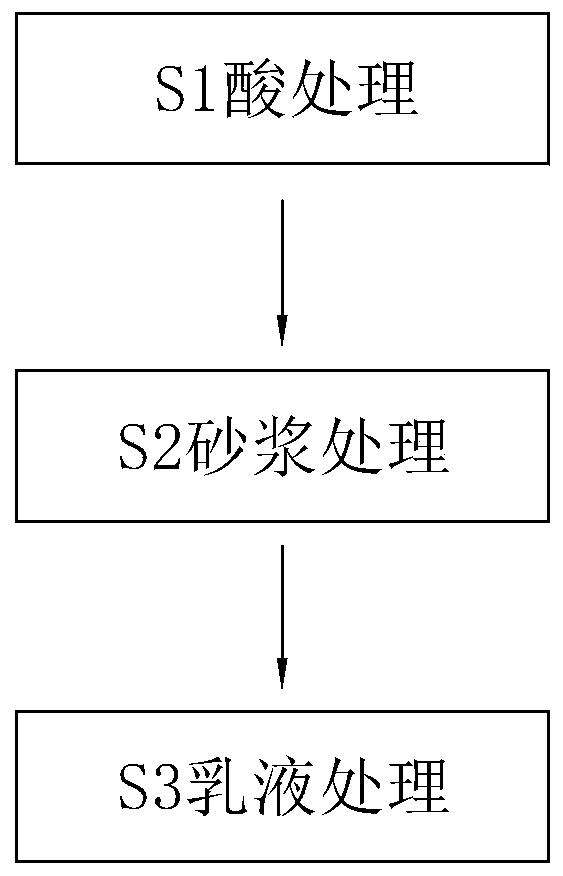

Method used

Image

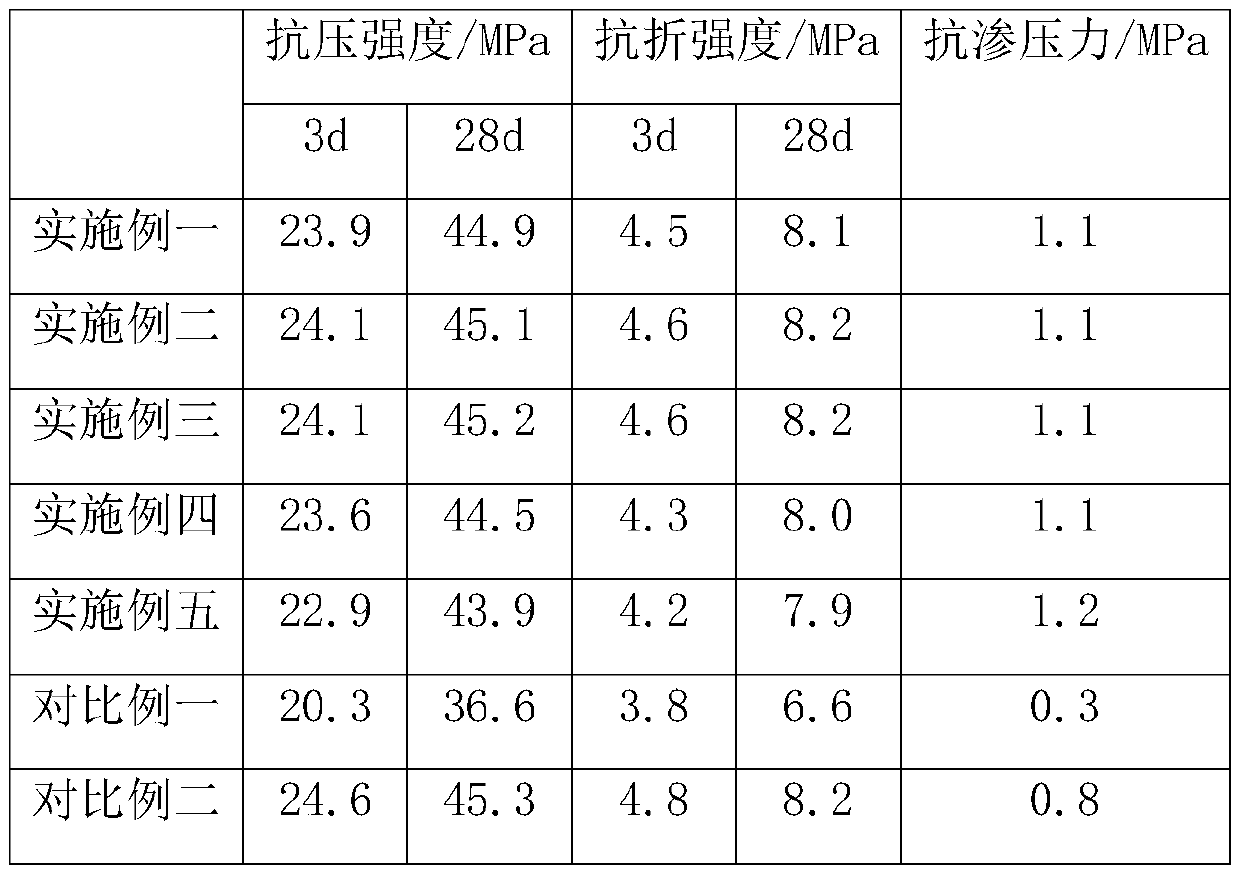

Examples

Embodiment 1

[0041] A high-performance concrete, comprising the following components by weight:

[0042] 350 parts of cement, the variety is P.O42.5;

[0043] 900 parts of coarse aggregate, the coarse aggregate includes 50% recycled aggregate and 50% crushed stone, the crushed stone is produced in Lishui Qingtian and has a continuous gradation of 5-31.5mm, the coarse aggregate of recycled aggregate primary concrete is crushed stone, The recycled aggregate is 5-31.5mm continuous gradation;

[0044] 540 parts of fine aggregate, the fine aggregate is medium sand, produced in Qingtian, Lishui;

[0045] 160 parts of water;

[0046] 190 parts of admixture, the admixture is compounded by mineral powder and fly ash with a mass ratio of 4:3;

[0047] 10 parts of admixture, the admixture is composed of expansion agent and water reducer with a mass ratio of 4:1, the model of the expansion agent is TD-AEA, and the water reducer is TD-5-3, both purchased from Shanghai Tongtai Concrete Admixtures Li...

Embodiment 2

[0059] A high-performance concrete, comprising the following components by weight:

[0060] 390 parts of cement, the variety is P.O42.5;

[0061] 1020 parts of coarse aggregate, the coarse aggregate includes 50% recycled aggregate and 50% crushed stone, the crushed stone is produced in Lishui Qingtian and has a continuous gradation of 5-31.5mm, the coarse aggregate of the recycled aggregate primary concrete is crushed stone, The recycled aggregate is 5-31.5mm continuous gradation;

[0062] 600 parts of fine aggregate, the fine aggregate is medium sand, produced in Qingtian, Lishui;

[0063] 180 parts of water;

[0064] 230 parts of admixture, the admixture is compounded by mineral powder and fly ash with a mass ratio of 4:3;

[0065] 14 parts of admixture, the admixture is composed of expansion agent and water reducer with a mass ratio of 4:1, the model of the expansion agent is TD-AEA, and the water reducer is TD-5-3, both purchased from Shanghai Tongtai Concrete Admixtur...

Embodiment 3

[0077] A high-performance concrete, comprising the following components by weight:

[0078] 370 parts of cement, the variety is P.O42.5;

[0079] 960 parts of coarse aggregate, the coarse aggregate includes 50% recycled aggregate and 50% crushed stone, the crushed stone is produced in Lishui Qingtian and has a continuous gradation of 5-31.5mm, the coarse aggregate of the recycled aggregate primary concrete is crushed stone, The recycled aggregate is 5-31.5mm continuous gradation;

[0080] 570 parts of fine aggregate, the fine aggregate is medium sand, produced in Qingtian, Lishui;

[0081] 170 parts of water;

[0082] 210 parts of admixture, the admixture is compounded by mineral powder and fly ash with a mass ratio of 4:3;

[0083] 12 parts of admixture, the admixture is composed of expansion agent and water reducer with a mass ratio of 4:1, the model of the expansion agent is TD-AEA, and the water reducer is TD-5-3, both purchased from Shanghai Tongtai Concrete Admixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com