Concrete expanding agent with triple expansion sources and preparation method of concrete expanding agent

An expansion agent and concrete technology, applied in the field of concrete additives, can solve the problems of disappearance, short expansion period, unfavorable long-term stability of cement strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

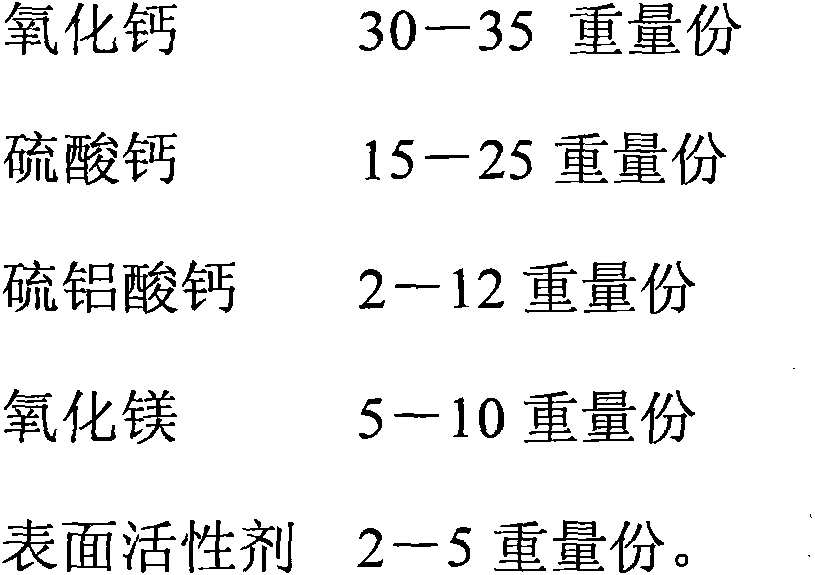

Method used

Image

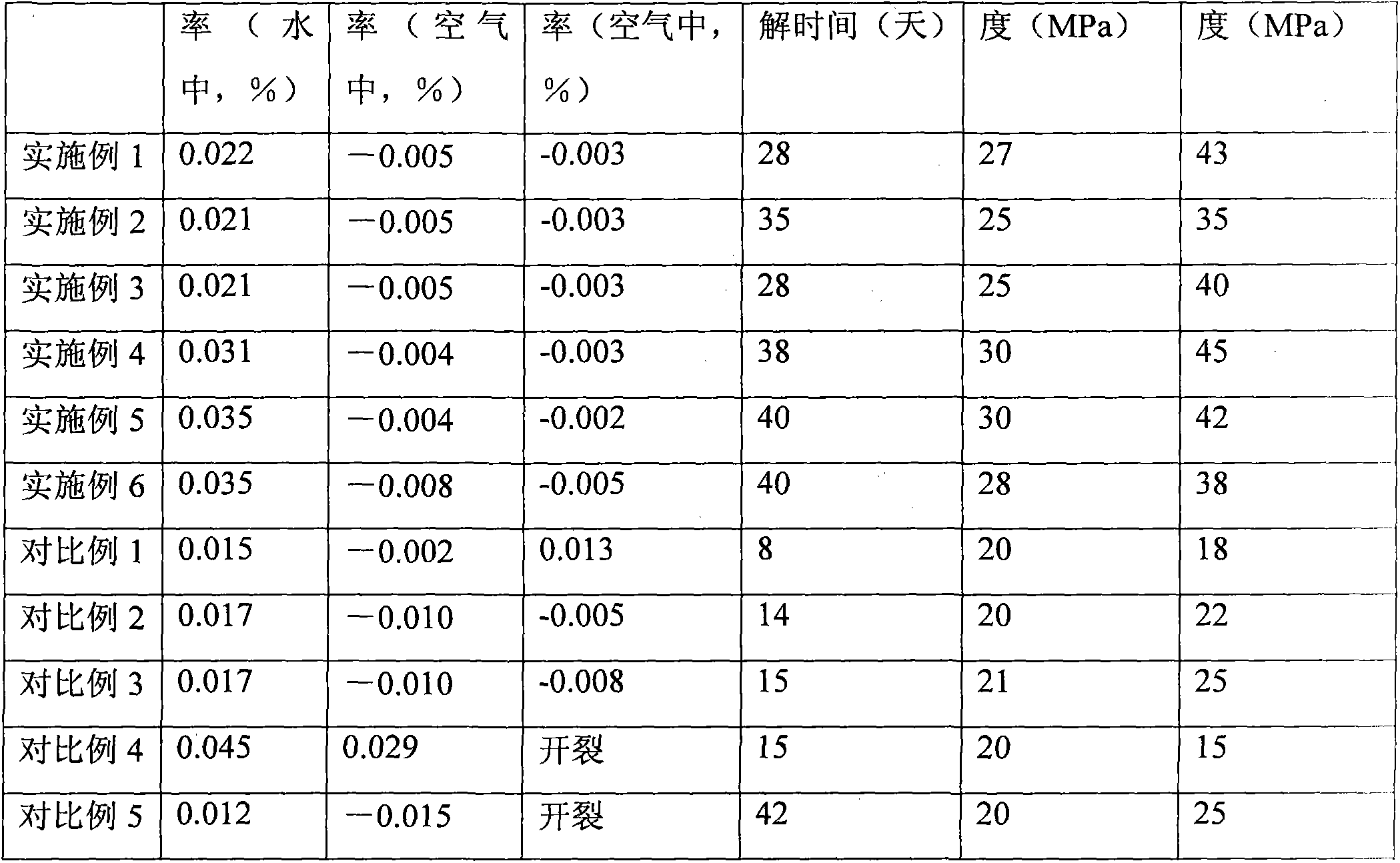

Examples

Embodiment 1

[0012] 30 parts by weight of calcium oxide, 20 parts by weight of calcium sulfate, 10 parts by weight of calcium sulfoaluminate and 6 parts by weight of magnesium oxide are jointly ground and then calcined at 1150°C-1200°C to form expanded clinker, and then three Ethanolamine, 100-120°C, mix well.

Embodiment 2

[0014] Other conditions are the same as in Example 1, except that calcium stearate is used instead of triethanolamine, and the obtained clinker is fully mixed with calcium stearate at 120-150° C. accordingly.

Embodiment 3

[0016] Other conditions were the same as in Example 1, except that the mixing of the clinker and triethanolamine was carried out at normal temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com