Prestressed concrete electrical pole and its production

A production process and concrete technology, applied in the field of concrete poles and their production processes, can solve the problems of uneven stress on steel bars, brittle failure, and large compressive stress of concrete bodies, and achieve cost savings of lines, improvement of concrete performance, and bearing capacity. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

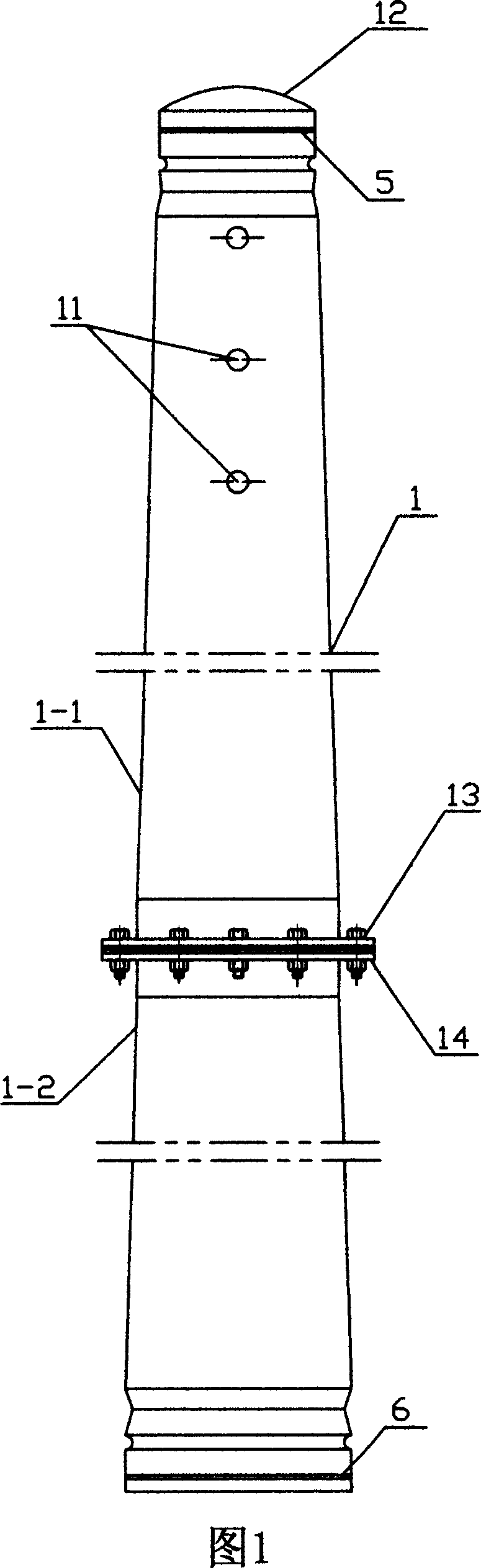

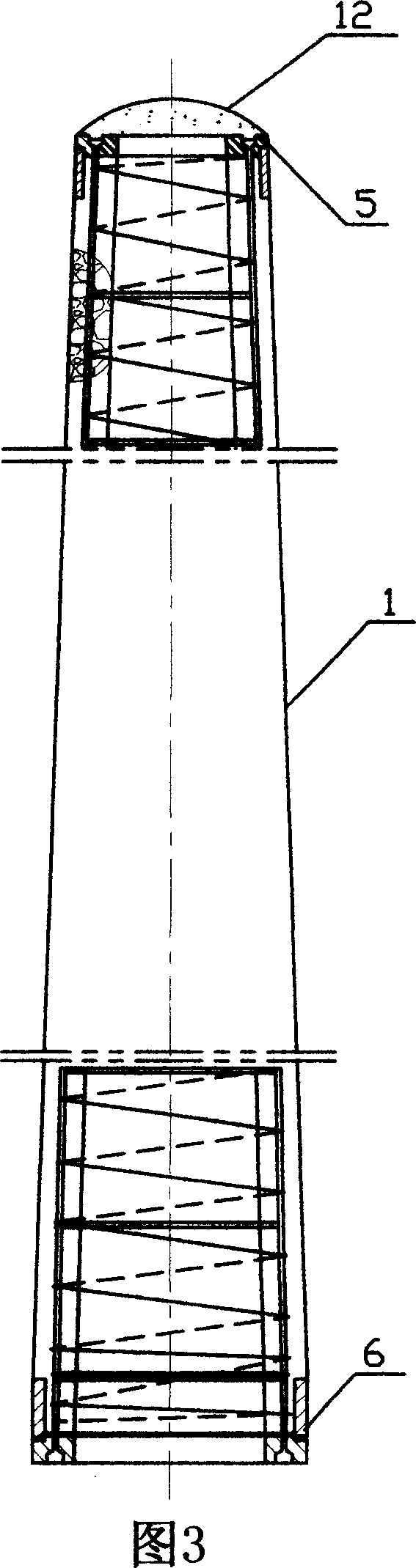

[0051] The design of the present invention is applicable to prestressed concrete poles with different pipe diameters and lengths, at least applicable to poles with a nominal diameter of Φ190 to Φ50, a length of 12m to 18m and more than 18m, so as to meet the different requirements of users, for example, Φ190× 18m, Φ230×18m, Φ310×18m, Φ350×18m, Φ230×15m, Φ190×12m, Φ190×15m, Φ350×12m, etc. Various specifications of electric poles, the taper of the pole is 1:75, and there is a single pole As shown in Figure 3, there are also two-section poles divided into upper and lower sections, as shown in Figure 1. For example, the two-section Φ190×18m can be divided into an upper section of 12m and a lower section of 6m. The head plates are connected by bolts, as shown in Figure 6 and Figure 7.

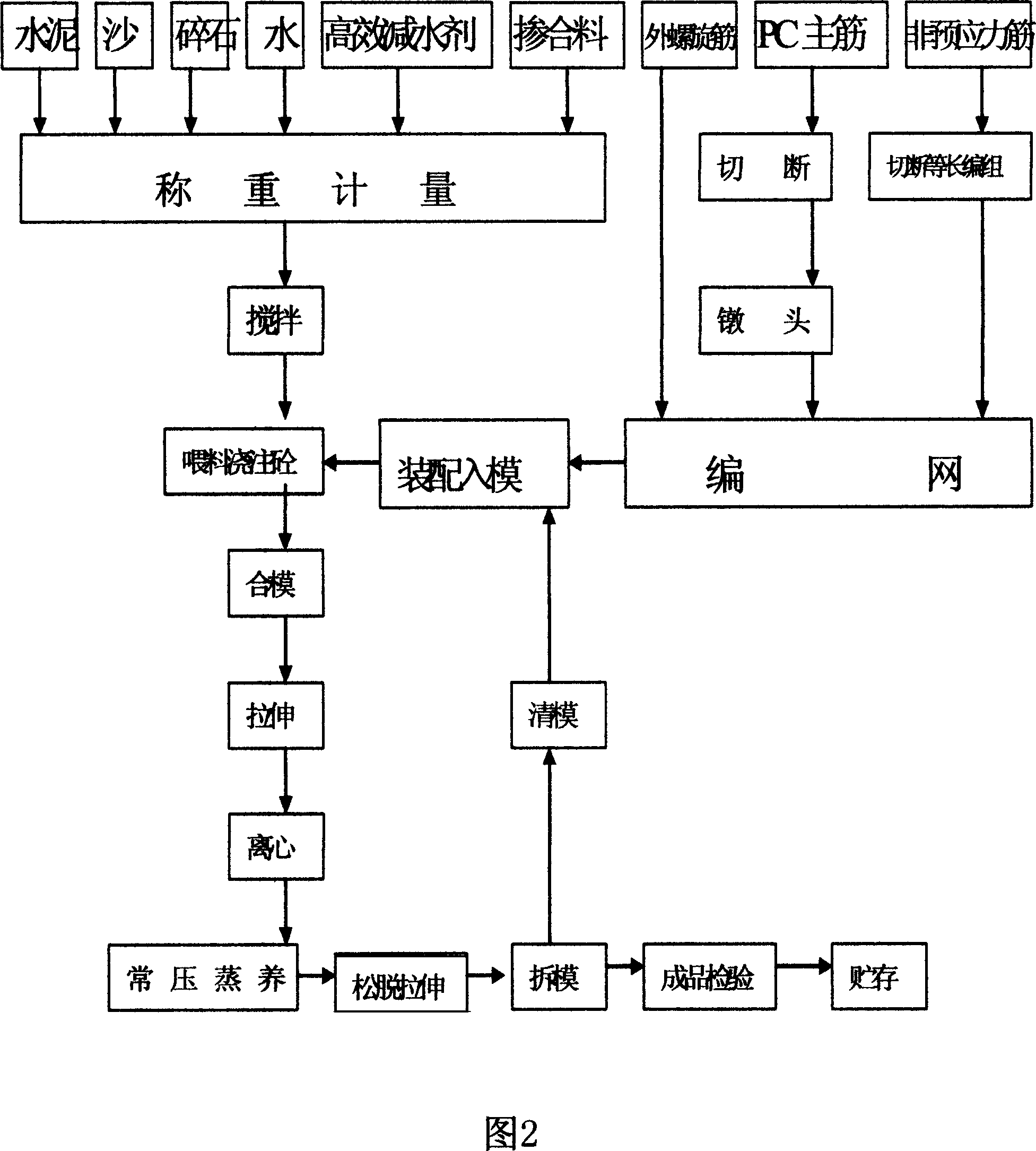

[0052] The electric pole of the present invention is composed of prestressed main ribs 3 and non-prestressed tendons 4, woven into a cage, assembled into a steel mold, poured into concrete slurry, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com